Tubular type double-annular channel double-sided heat-exchange large-flux microchannel reactor

A micro-channel reactor, double-ring technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the increase in the complexity and cost of microreactor detection and control, etc. problems, to solve dangerous problems, reduce floor space, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

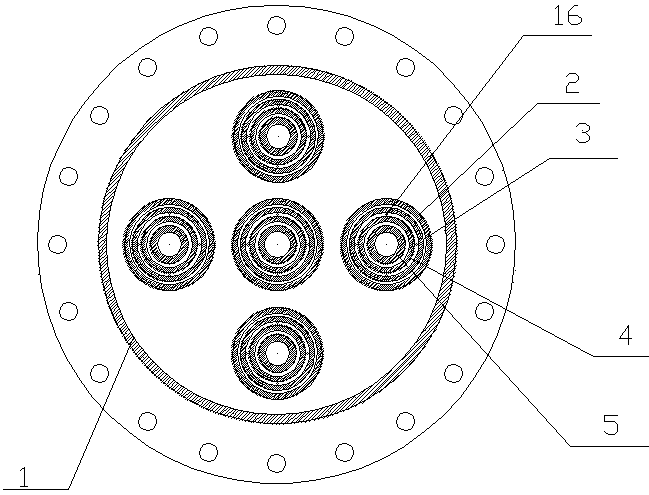

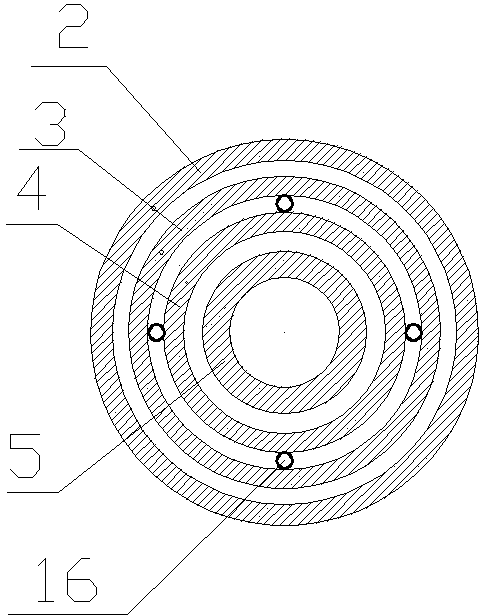

[0029] like Figure 1-3As shown, the tube-type double-annular channel double-sided heat exchange microchannel reactor includes: cylinder 1, column tube 2, isolation sleeve 3, middle sleeve 4, inner sleeve 5, No. 1 flange 6, three No. 7 flange tube plate, No. 3 flange 8, No. 1 head 9, No. 2 tube box 10, No. 2 flange 11, No. 2 flange tube plate 12, No. 1 tube box 13, No. 1 flange tube Plate 14, baffle plate 15, fixed-distance round steel 16, No. 2 head 17, supporting flower plate 18, No. 4 flange 19 and No. 4 flange tube plate 20, and one end of cylinder 1 is welded to No. 1 flange On the tube plate 14, the other end of the cylinder 1 is welded on the No. 4 flange tube plate 20. The cylinder 1 has a baffle 15 inside, and the cylinder 1 is provided with a heat exchange medium inlet and a heat exchange medium outlet. The tubes 2 are set in the cylinder body 1, one end of the tubes 2 is welded on the No. 1 flange tube plate 14, the other end of the tubes 2 is welded on the No. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com