Waterproof down jacket making method and waterproof down jacket

A production method and technology for down jackets, applied in the field of down jackets, can solve the problems of low fastness of seamless fit, poor waterproof and anti-drilling effect at the splicing parts of garment pieces, etc. Improve waterproof performance and improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

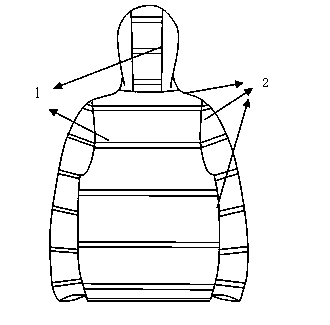

Image

Examples

Embodiment 1

[0022] The whole process of making the whole waterproof down jacket mainly includes the following steps:

[0023] Step 1: Material selection: the surface fabric is water pressure resistant above 10000mmwc, and the weight is 133g / m 2 100% coated nylon fabric; middle layer fabric weight 77g / m 2 Polyester woven fabric; the inner fabric has a ventilation rate of 1.0cc / cm 2 Below / sec, the weight is 102g / m 2 Pure polyester calendered fabric.

[0024] Step 2: Plate making, plate verification, and cutting according to the template.

[0025] Step 3: Quilting, seamless fit: first quilting the middle layer fabric and the inner layer fabric of the back body, sleeves, collar, hat and other parts with sewing thread, and adding the front body piece between the middle layer and the inner layer A layer of bag cloth, quilting the middle layer fabric and bag cloth fabric with sewing thread; then iron the double-sided adhesive tape on the quilting line of each part, and then place the surfac...

Embodiment 2

[0034] The whole process of making the whole waterproof down jacket mainly includes the following steps:

[0035] Step 1: Material selection: the surface fabric is water pressure resistant above 10000mmwc, and the weight is 133g / m 2 Laminated and processed pure polyester fabric; the middle layer fabric has a weight of 85g / m 2 Polyester mesh fabric; the inner layer fabric weighs 102g / m 2 Calendered pure polyester fabric.

[0036] Step 2: Plate making, plate verification, and cutting according to the sample; the middle layer fabric is cut into two layers.

[0037] Step 3: Quilting and seamless fit: First, quilt the two layers of middle layer fabric and inner layer fabric of the back body, sleeves, collar, hat and other parts with sewing thread, and place the front body on the inner layer of the middle layer Add a layer of bag cloth between the inner layer and the two layers of middle layer fabric and bag cloth fabric with sewing thread; then place the surface layer fabric on ...

Embodiment 3

[0046] The whole process of making the whole waterproof down jacket mainly includes the following steps:

[0047] Step 1: Material selection: the surface fabric is water pressure resistant above 10000mmwc, and the weight is 120g / m 2 100% coated nylon fabric; the middle layer is 30g / m 2 , 80% nylon and 20% polyester are non-adhesive non-woven interlinings; the inner fabric has a ventilation volume of 1.0cc / cm 2 Below / sec, weight 102g / m 2 Pure polyester fabric after calendering.

[0048] Step 2: Plate making, plate verification, and cutting according to the template.

[0049] Step 3: Quilting, seamless fit: First, quilt the middle layer of non-adhesive non-woven interlining and the inner fabric of the back body, sleeves, collars, hats, etc. A layer of pocket cloth is added between the inner layers, and the non-adhesive non-woven interlining and pocket fabric of the middle layer are quilted with sewing thread; The press is hot-pressed and laminated. When laminating, about 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com