Guide clamping lock type high branch pruning and stubble protecting saw

A locking and high branch technology, applied in plant protection, cutting tools, cutting equipment, etc., can solve problems such as backward pruning and stubble maintenance technology, low work efficiency in the pruning process, and difficult positioning of pruning saws, etc. Sustained development, light weight and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

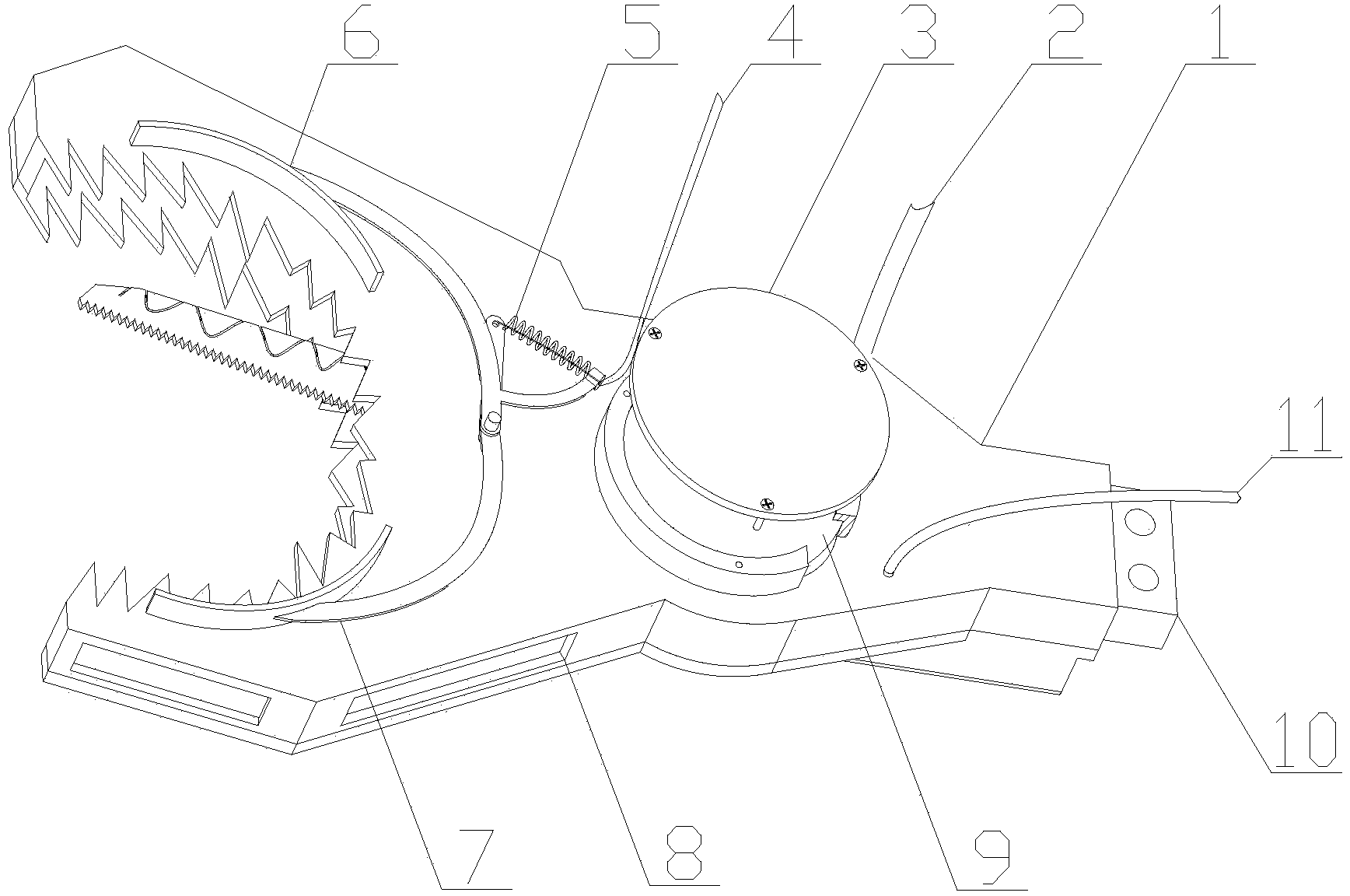

[0021] Such as Figure 1~4 As shown, 1 main housing, 2 drug delivery tube, 3 bearing inspection cover, 4 clamping brake line, 5 clamping spring, 6 No. 1 clamping claw, 7 No. 2 clamping claw, 8 chip discharge port, 9 bearing , 10 connection block, 11 pruning gate line, 12 saw blade inspection cover, 13 pair of shells, 14 clamping push rod, 15 liquid medicine tank, 16 pruning push rod, 17 motor, 18 bevel gear, 19 coaxial gear , 20 guide plate springs, 21 connecting rods, 22 guide plates, 23 sliders, 24 fan nozzles, 25 medicine storage saw blades, 26 eccentric wheels, 27 cylindrical gears.

[0022] A guide-and-lock type high-branch pruning and stubble protection saw includes a housing mechanism, a clamping mechanism, a pruning mechanism and a stubble maintenance mechanism.

[0023] The housing mechanism includes a main housing 1 , a bearing inspection cover 3 , an auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com