Method for manufacturing valve for internal combustion engine

A manufacturing method and technology of an internal combustion engine, which are applied to lift valves, valve devices, mechanical equipment, etc., can solve the problems of indentation, deterioration of gas channeling resistance, insufficient hardness of the umbrella surface, etc. Effects of improved blow-by and improved hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] for the manner in which the invention is carried out

[0052] Hereinafter, referring to the accompanying drawings, the embodiment method of the present invention will be described in detail.

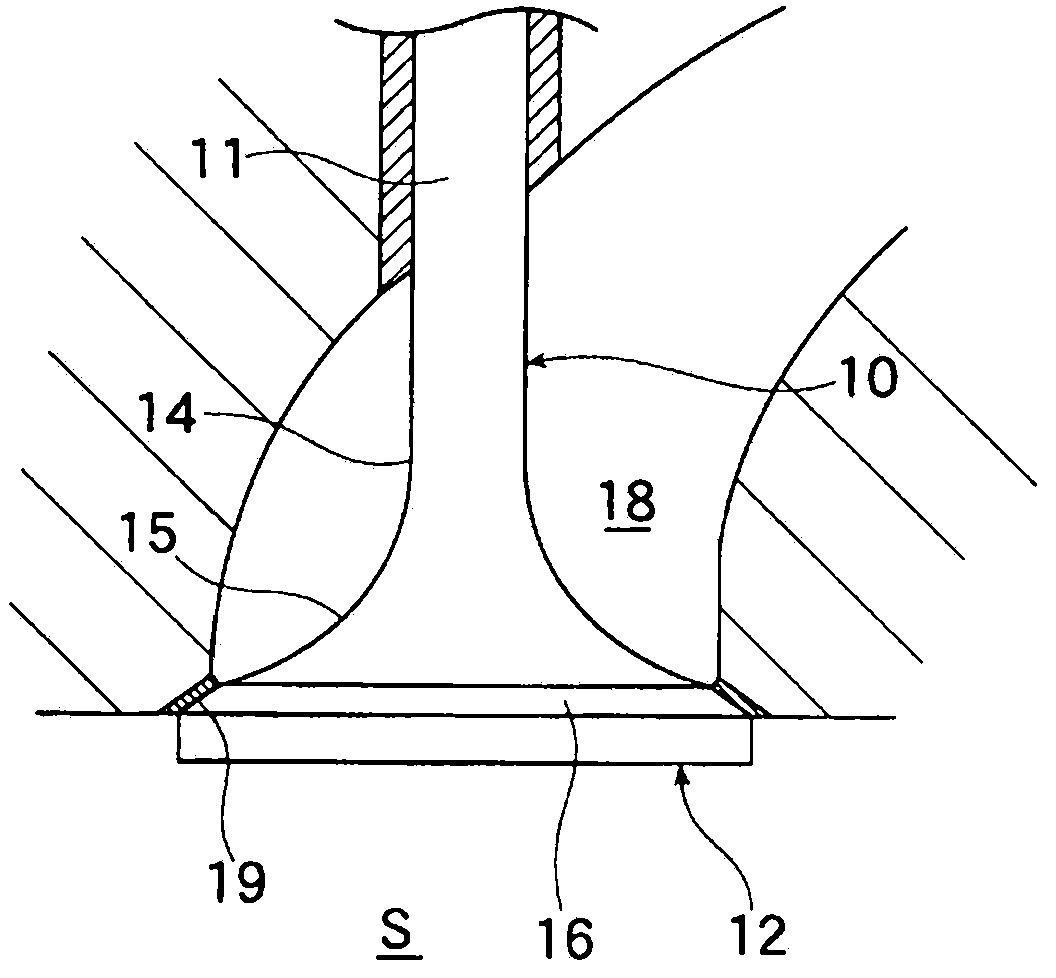

[0053] figure 1 The symbol 10 in is the poppet valve for an internal combustion engine manufactured by the manufacturing method of the present invention, which is made of heat-resistant alloys such as precipitation hardening Ni-based alloys (for example, NCF80A, NCF751), and the umbrella part 12 passes through the neck 14 and the R part 15 It is integrally formed on the front end side of the stem 11 . A surface 16 connected to the R portion 14 and in contact with a valve seat 19 provided on the periphery of an exhaust port (or intake port) 18 opening to the combustion chamber S is formed on the back side of the cap portion 12 .

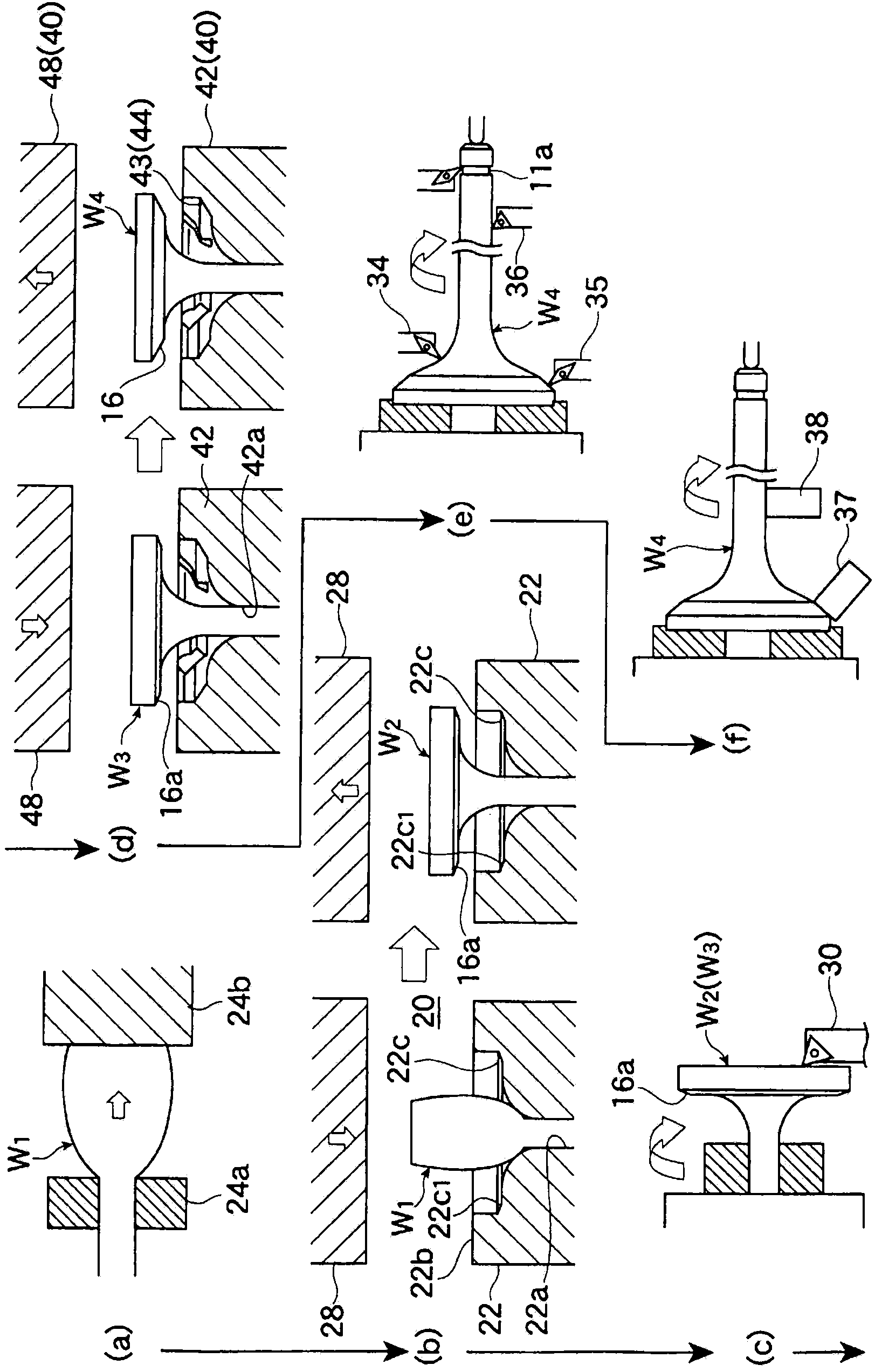

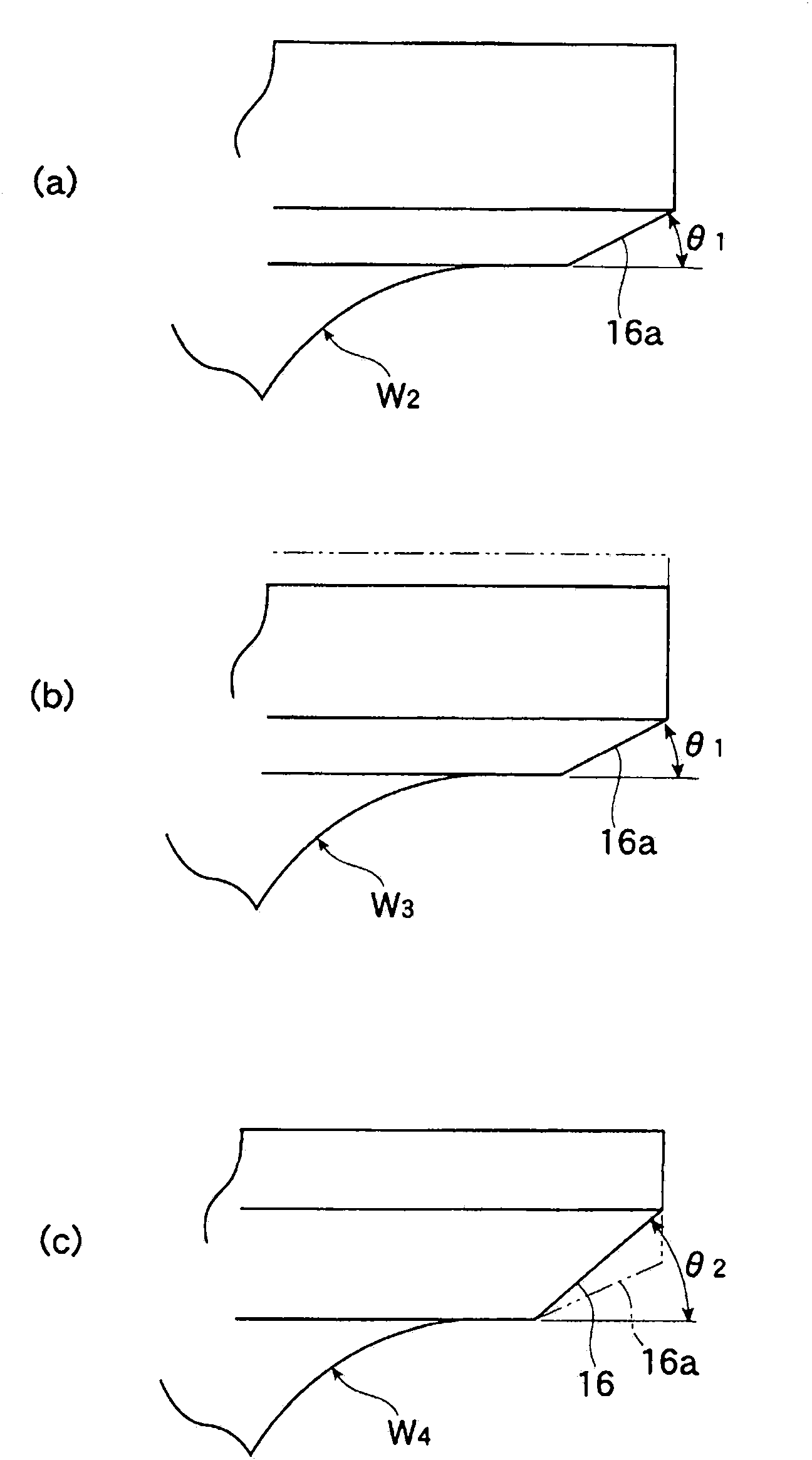

[0054] figure 2 is manufacturing figure 1 The diagram of the entire process of the first embodiment method (hereinafter referred to as embodiment me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com