Manufacturing method of stress sensor based on nanorod diode piezoelectric effect

A technology of stress sensor and piezoelectric effect, applied in the field of preparation of stress sensor, can solve the problems of narrowing of effective bandwidth and red shift of emission wavelength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

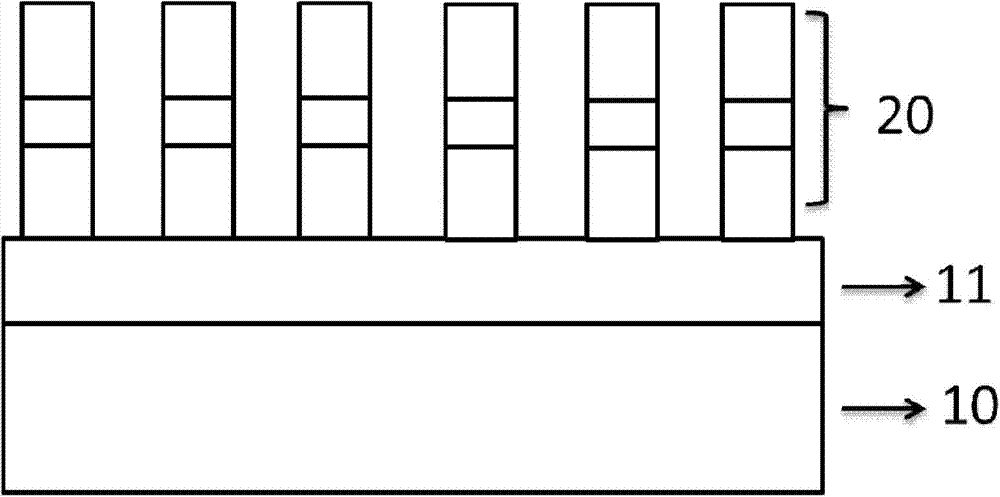

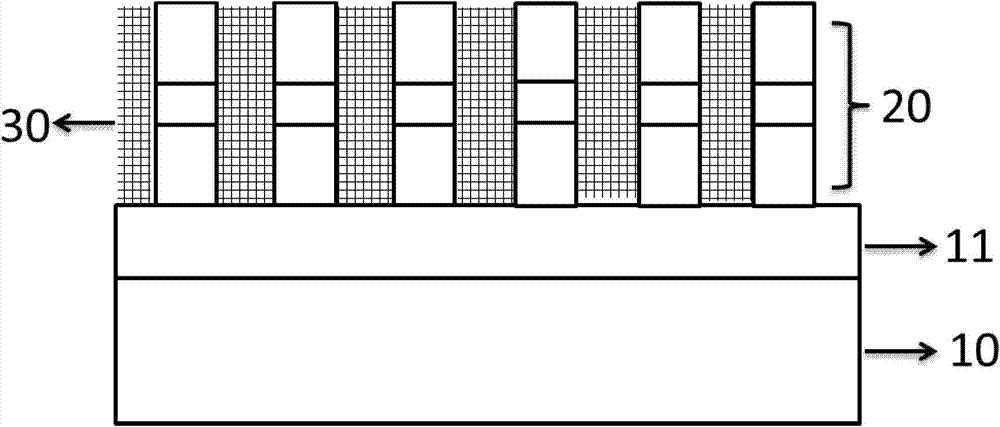

[0020] see Figure 1 to Figure 7 , the present invention provides a method for preparing a stress sensor based on the nanocolumn diode piezoelectric effect, comprising the following steps:

[0021] Step 1: Take a substrate 10, grow a layer of thin film n-type GaN11 on the substrate 10, then grow a layer of multi-quantum well active region, that is, MQWs12 and p-type GaN, that is, p-GaN13; finally, p-GaN13 , forming a complete LED structure, and finally self-assemble a layer of densely arranged nanosphere array 14 on the surface of p-GaN13; wherein, the substrate 10 is a sapphire substrate, and can also be glass, Si, ZnO, AlN, SiC , GaN, GaAs, LiAlO 2 Other III / V, IV / VI binary, ternary and quaternary compound semiconduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com