Method and device for automatically planting optical fiber into composite materials based on fiber laying and placing

A composite material and fiber laying technology, which is applied in the direction of measuring the changing force of the optical properties of the material when it is stressed, can solve the problem of inability to meet the requirements of large-scale high-precision production, low optical fiber positioning accuracy, and low implantation efficiency. and other problems, to achieve the effect of preventing torsional deformation, improving manufacturing accuracy and quality, and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

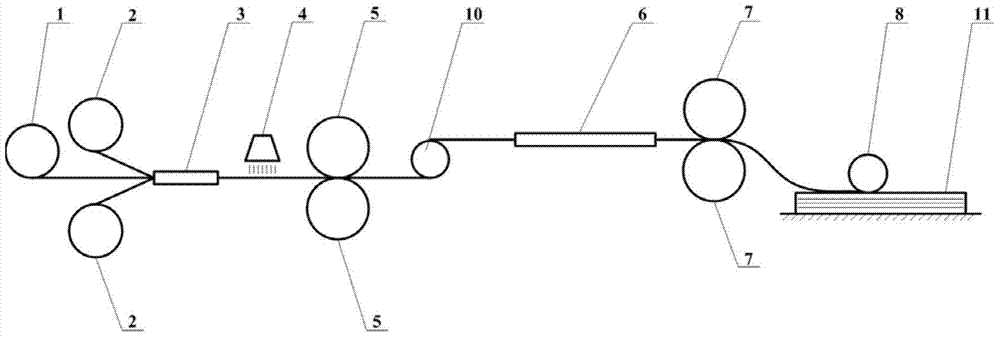

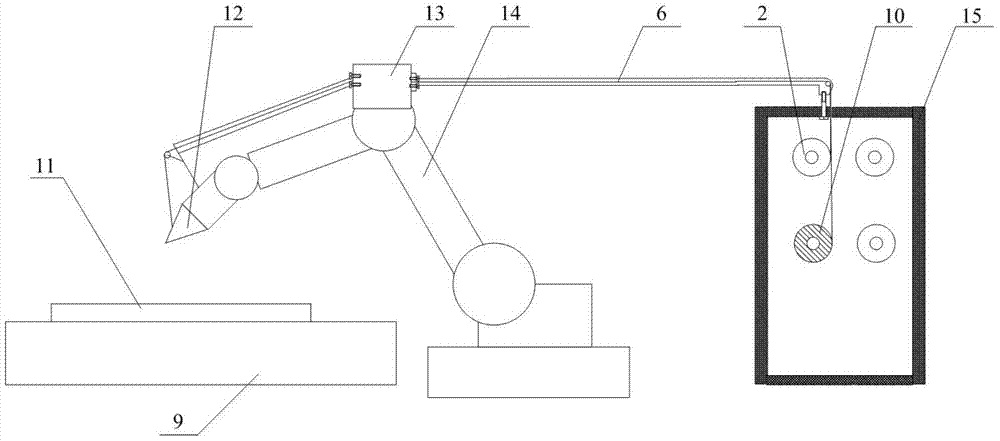

[0028] refer to Figure 1 to Figure 4 A method for automatically implanting an optical fiber into a composite material based on fiber laying provided by the present invention comprises the following steps:

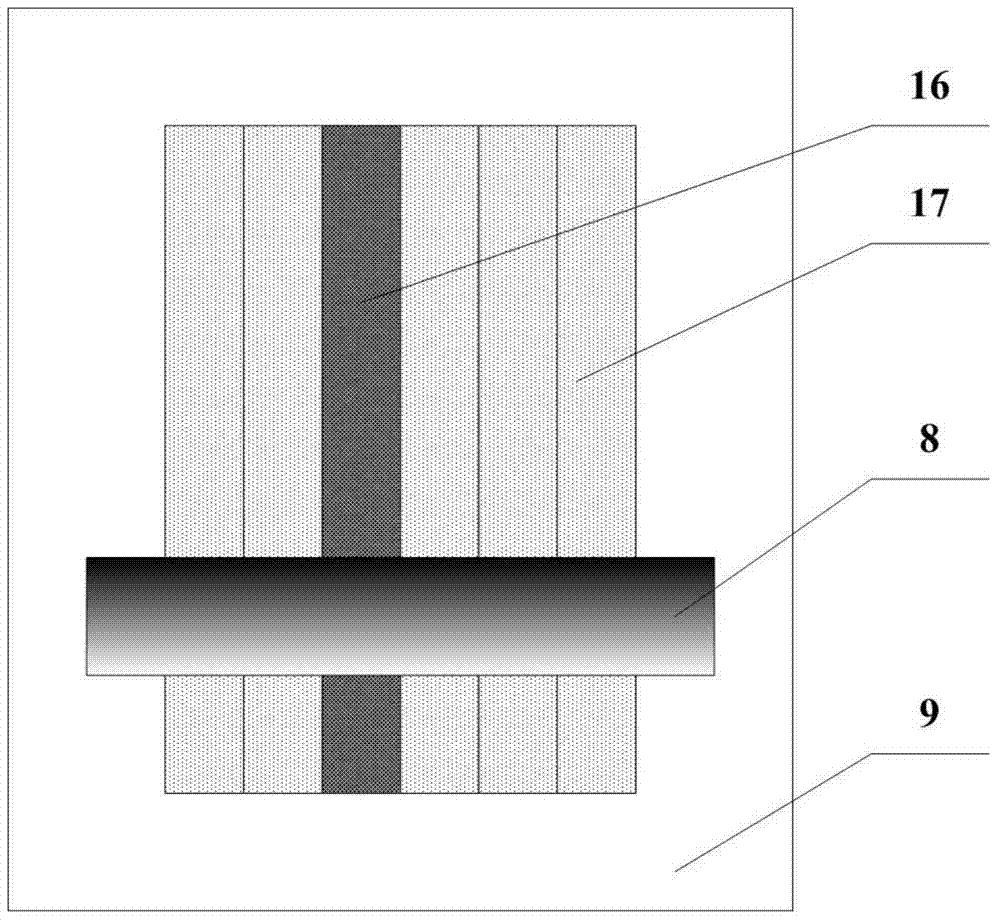

[0029] 1) Place the optical fiber winding roll 1 wound by the optical fiber 18 between two single-layer prepreg tape rolls 2, so that the optical fiber 18 and the single-layer prepreg tape 17 are driven by the flexible pressure roller 5 through the conveying channel 3 directions Front conveying, in which the conveying channel 3 plays the role of constraining and positioning the optical fiber 18 and the single-layer prepreg tape 17; then it is heated by the infrared lamp heating device 4, and the heating temperature is 40-50°C. Since the surface of the single-layer prepreg tape 17 is coated Covered with resin, the viscosity of the resin is increased by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com