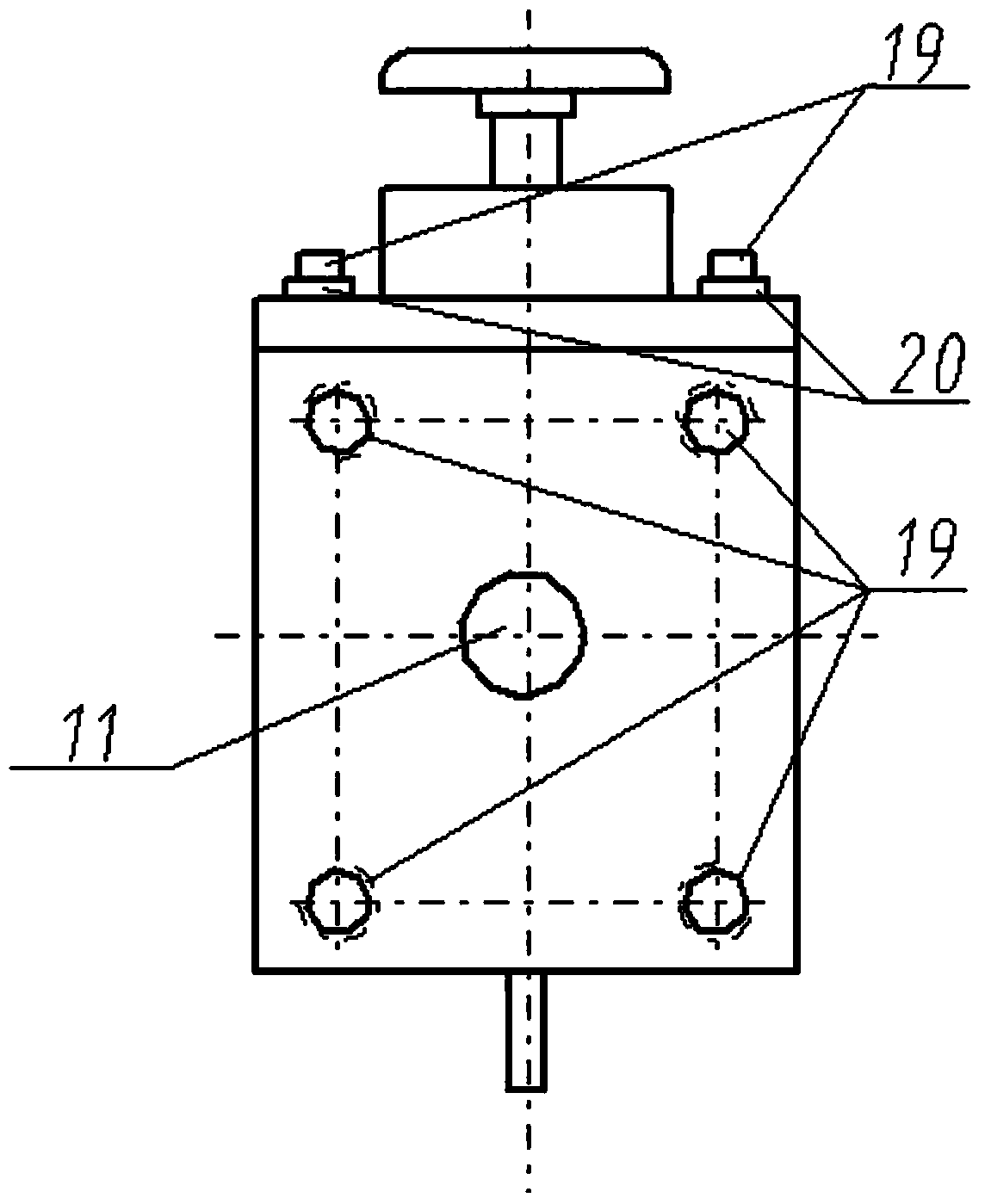

Portable and quick-open type high-pressure stop valve

A quick-opening, shut-off valve technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of longer opening and closing time of the shut-off valve, large opening and closing, and large diameter of the valve stem, so as to shorten the opening time , reduce the opening force, reduce the effect of spring preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Turn the adjustment handwheel (18) to move the spool pressure rod (16) up to the predetermined position. At this time, both the main spool spring (14) and the auxiliary spool spring (12) have a certain pretightening force to close the stop valve. , that is, the taper mating surfaces of the main valve core (7) and the main valve port (6) on the valve body (1), the auxiliary valve core (10) and the auxiliary valve port (8) at the lower end of the main valve core (7) are all It plays a sealing role, so that the water inlet and the water outlet are not connected; when the high-pressure liquid enters the stop valve through the water inlet, the solution enters the main valve core (7) through the four flow channel holes uniformly distributed along the circumferential direction of the axis. In the cavity of the spool (7), the upper and lower surfaces of the cavity of the main spool (7) are subject to the same pressure. Push the spool push rod (2) to move up, the auxiliary spool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com