Paving structure of geothermic solid wood floor

A solid wood flooring and geothermal technology, applied to building structures, floors, insulation layers, etc., can solve problems such as cracking and warping, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for installing a solid wood geothermal floor, which includes:

[0039] Step S1: providing the ground to be paved;

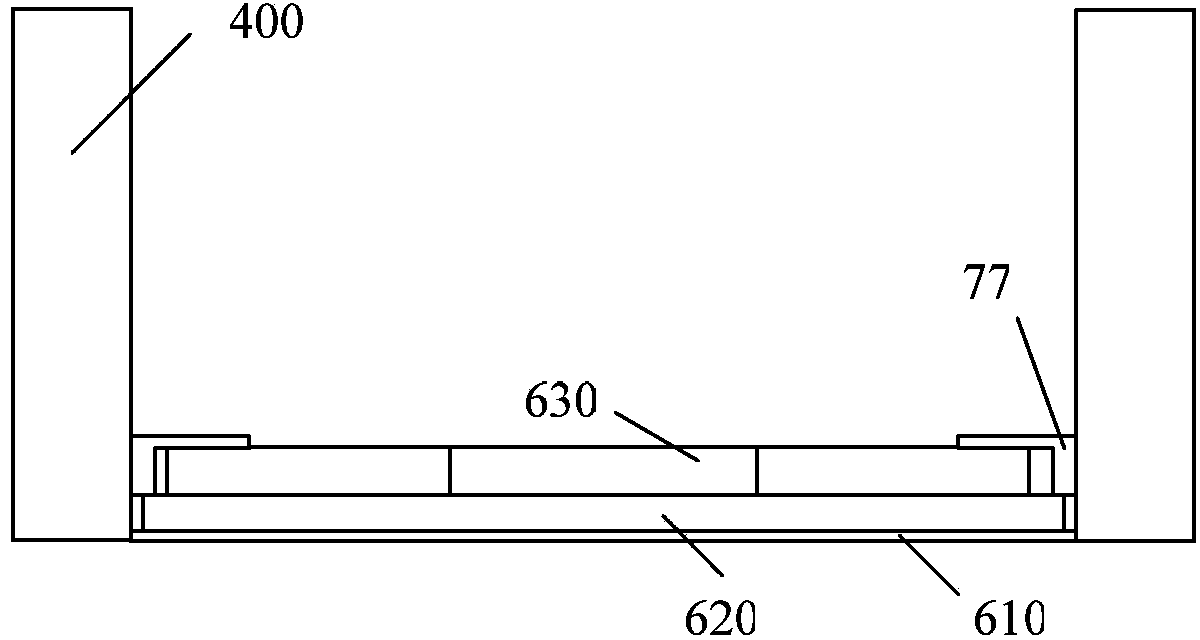

[0040] Generally, the ground to be paved is a flat ground paved with indoor cement, surrounded by structures such as walls or thresholds. Specifically, the ground to be paved needs to be inspected and repaired before paving, so that the surface height of the ground to be paved within 2 square meters does not exceed 3 mm. Then, the geothermal equipment is turned on, and the geothermal heating test is carried out, and at the same time, the temperature raised by the geothermal heating test is used to discharge moisture, so that the moisture content of the ground to be paved is less than or equal to 10%. Before the paving of the next step, that is, before the soft material layer is laid on the ground to be paved, a layer of plastic cloth is laid on the ground to be paved to avoid moisture on the ground after the solid wood fl...

Embodiment 2

[0059] In addition to adopting the direct paving method and structure in Embodiment 1, the geothermal solid wood floor laid in this embodiment has also undergone special processing to be more suitable for the geothermal environment. Specifically, the special process is water content balance treatment, which includes:

[0060] Step p31: providing solid wood floor blanks;

[0061] Generally, the solid wood floor blank is a plurality of strip-shaped solid wood boards with roughly the same shape and size. In this embodiment, its size is 90cm*15cm*4cm. In other embodiments, other sizes may be used, depending on the designed size of the final shaped geothermal solid wood floor.

[0062] Step p32: stacking the solid wood floor blanks in layers, and separating each layer with a spacer;

[0063] Stack the solid wood floor blanks layer by layer and neatly, each layer is separated by a spacer with a cross-section of 2cm*2cm, and a spacer is placed every 20cm or so to ensure that the st...

Embodiment 3

[0084] In addition to the direct paving method and structure provided in Embodiment 1, and the moisture content balance treatment provided in Embodiment 2, the geothermal solid wood floor provided in Embodiment 3 also has a special lock and buckle structure.

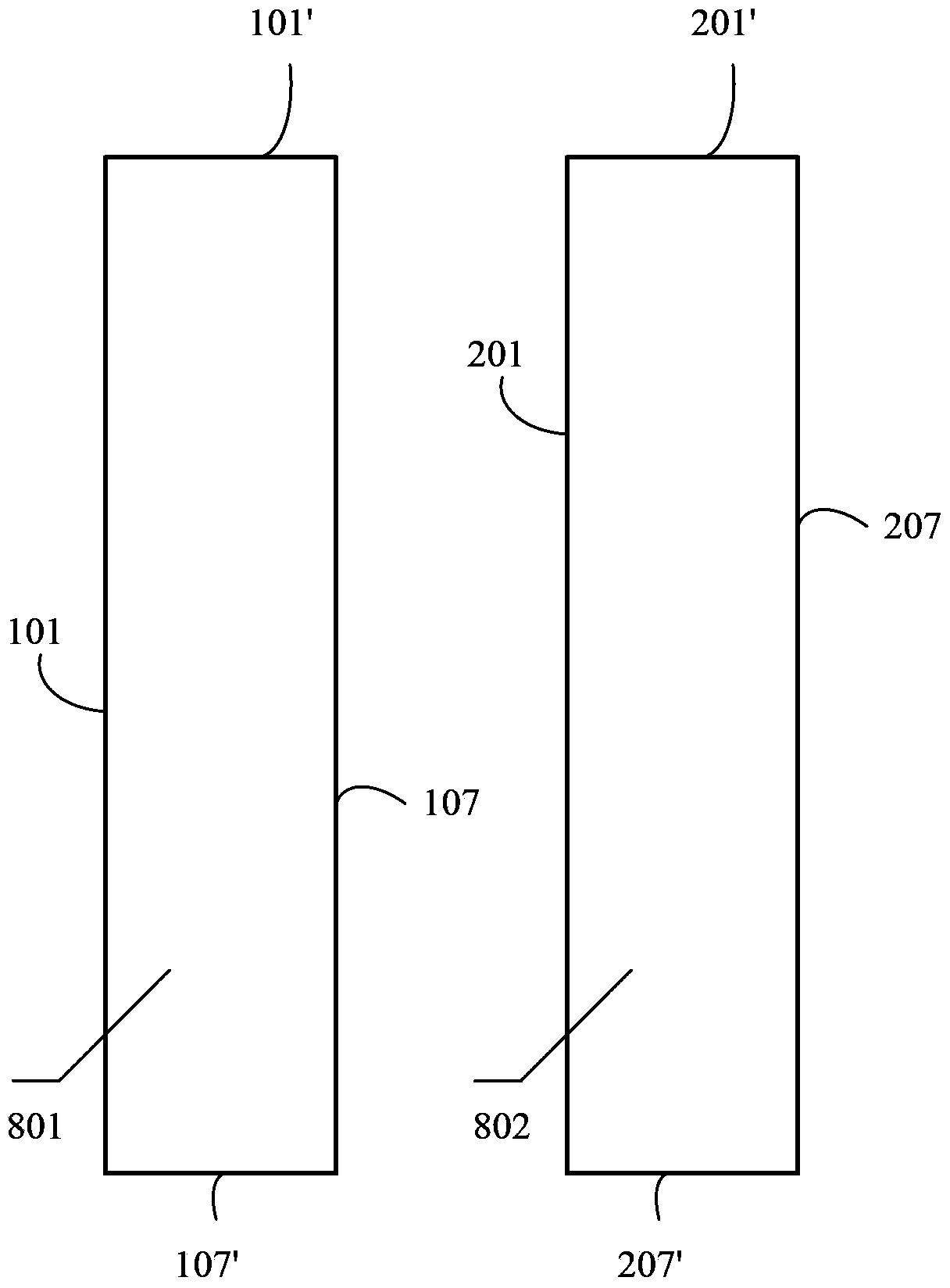

[0085] Specifically, the buckle or buckle method of the geothermal solid wood floor is two structures that require two adjacent floors to cooperate with each other, and it needs to involve such as image 3 The opposite edges of two adjacent floors are shown, such as the opposite edge 107 and edge 201 of the floor 801 and the floor 802, the edge 101 and the edge 207, the edge 107' and the edge 201' or the edge 101' and the edge 207'.

[0086] Wherein, in this application document, the said locking structure refers to the matching mode of the two mating edges of the two adjacent floor boards involved in the horizontal horizontal and vertical directions, and the two edges have a structure that engages with each other , one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com