Cable-loaded crane combined with hydraulic traction and roller travel and its travel method

A cable-mounted crane and traveling mechanism technology, which is used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of one-time re-installation, only dismantling, and inconvenient operation, and achieves easy disassembly and assembly, convenient position adjustment, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

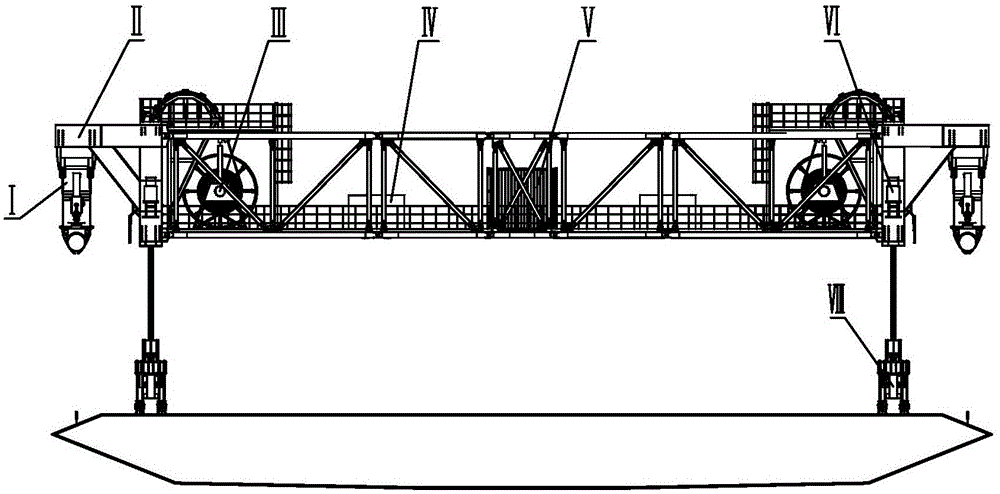

[0072] A cable-loaded crane combined with hydraulic traction and roller travel, such as Figure 1-1~Figure 1-2 As shown, the cable-loaded crane combined with hydraulic traction and roller travel includes traveling mechanism Ⅰ, steel truss Ⅱ, steel strand retracting device Ⅲ, diesel engine hydraulic pump station Ⅳ, control system Ⅴ, lifting jack and cage Ⅵ and hanging Tool Ⅷ; traveling mechanism Ⅰ is installed at both ends of steel truss Ⅱ, steel strand retracting device Ⅲ, diesel engine hydraulic pump station Ⅳ, control system Ⅴ, lifting jack and cage Ⅵ are installed in steel truss Ⅱ, spreader Ⅷ passes through steel truss The twisted wire is connected to the lifting jack;

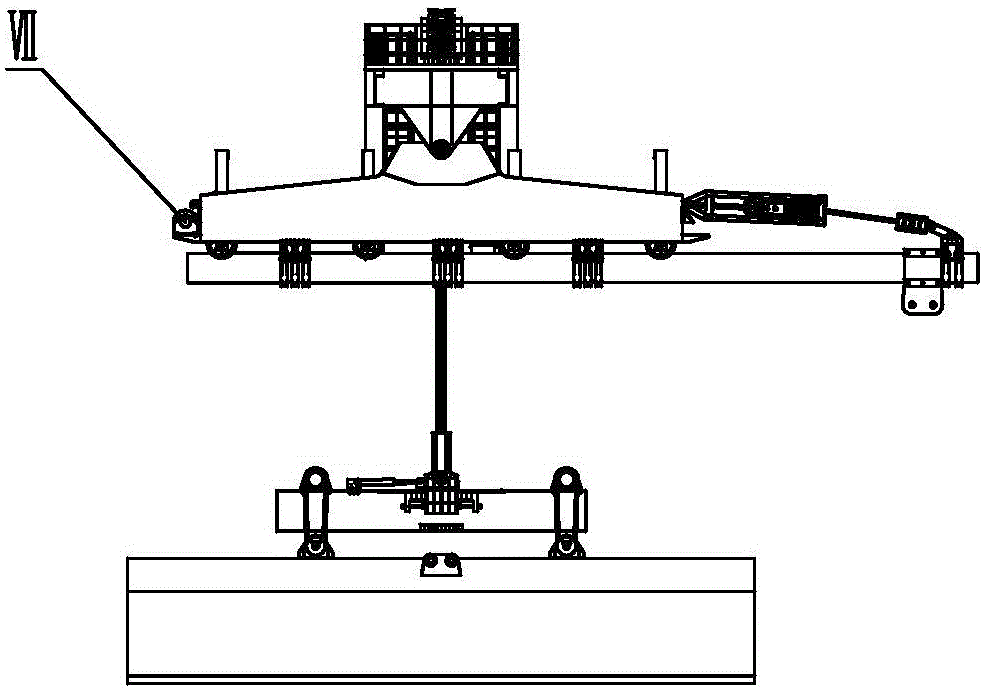

[0073] As shown in Figure 2-1, the traveling mechanism is composed of four load conversion devices 1, holding feet 2, traveling mechanism main body 3, hoop 4, traction frame 5, traction jack 7 and traction fixing device 8;

[0074] Described load conversion device 1 comprises load conversion jack 11, suppo...

Embodiment 2

[0083] The walking method of the cable-loaded crane combined with hydraulic traction and roller walking. The walking of the cable-loaded crane adopts the combination of hydraulic traction and roller walking. The crane moves from the high point of the main cable to the low point of the main cable. The so-called upward movement means that the cable-loaded crane moves from the low point of the main cable to the high point of the main cable;

[0084] The process of the cable-loaded crane going down is (see Figure 7-1 and Figure 7-2):

[0085] The traction fixing device withstands the cable clamp as a reaction point, the traction frame as a force transmission part, and the hydraulic traction jack provides resistance; when the cable-loaded crane is going to travel, the load conversion jack of the load conversion device lifts the cylinder, and the 4 traveling rollers are all connected to the main Cable contact, the entire cable-loaded crane is jacked up, the upper clamp of the tracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com