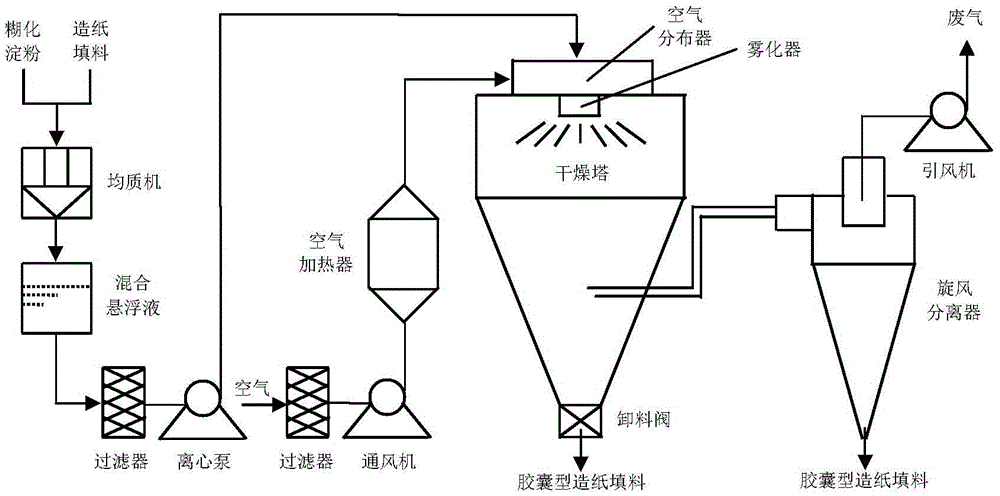

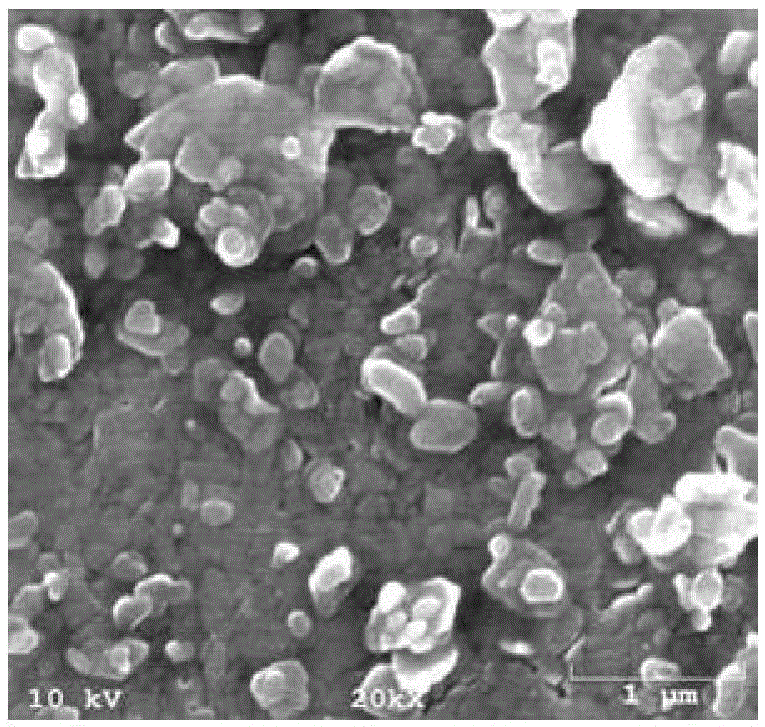

Method for preparing capsule-type paper-making filler by spray-drying starch

A papermaking filler and spray dryer technology, which is applied in the papermaking field, can solve the problems of a large decline in paper strength properties, unbearable effects for papermaking enterprises, and insignificant effects, and achieves obvious modification effects, improved quality, and improved physical strength properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]1) Weigh 100 kg of ordinary cornstarch, add 4900 kg of deionized water to prepare a starch suspension with a concentration of 2% by mass, stir and disperse evenly, and perform starch gelatinization. The starch gelatinization process is as follows: the stirring speed is 150rpm, the gelatinization temperature is 95°C, and the gelatinization time is 60min.

[0041] 2) Weigh 500 kg of light calcium carbonate with a particle size of 1250 mesh, add 2000 kg of deionized water to prepare a filler suspension with a mass percentage concentration of 20%, and then use a continuous high-shear homogenizer at a speed of 12000rpm Disperse evenly.

[0042] 3) Mix the gelatinized starch obtained in step 1) and the homogeneous paper-making filler obtained in step 2), and then perform homogenization treatment with a continuous high-shear homogenizer. The speed of homogenizer is 10000rpm.

[0043] 4) After the mixed suspension of starch and paper-making filler obtained in step 3) is spray-...

Embodiment 2

[0047] 1) Weigh 62.5 kg of potato starch and add 1500 kg of deionized water to prepare a starch suspension with a concentration of 4% by mass. Stir and disperse evenly before starch gelatinization. The starch gelatinization process is as follows: the stirring speed is 180rpm, the gelatinization temperature is 95°C, and the gelatinization time is 80min.

[0048] 2) Weigh 500 kg of kaolin with a particle size of 1250 mesh, add 1500 kg of deionized water to prepare a filler suspension with a concentration of 25% by mass, and then use a continuous high-shear homogenizer to disperse evenly at a speed of 14000 rpm.

[0049] 3) Mix the gelatinized starch obtained in step 1) and the homogeneous paper-making filler obtained in step 2), and then perform homogenization treatment with a continuous high-shear homogenizer. The speed of homogenizer is 12000rpm.

[0050] 4) After the mixed suspension of starch and paper-making filler obtained in step 3) is spray-dried by a centrifugal spray ...

Embodiment 3

[0054] 1) Weigh 60 kg of cationic starch, add 2340 kg of deionized water to prepare a starch suspension with a concentration of 2.5% by mass, stir and disperse evenly, and perform starch gelatinization. The starch gelatinization process is as follows: the stirring speed is 180rpm, the gelatinization temperature is 90°C, and the gelatinization time is 90min.

[0055] 2) Weigh 600 kg of talc powder with a particle size of 1250 mesh, add 2400 kg of deionized water to prepare a filler suspension with a concentration of 20% by mass, and then use a continuous high-shear homogenizer to disperse evenly at a speed of 14000 rpm .

[0056] 3) Mix the gelatinized starch obtained in step 1) and the homogeneous paper-making filler obtained in step 2), and then perform homogenization treatment with a continuous high-shear homogenizer. The speed of homogenizer is 10000rpm.

[0057] 4) After the mixed suspension of starch and paper-making filler obtained in step 3) is spray-dried by a centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com