A method of using pet to produce flat yarn

A technology of flat yarn and polyester chips, which is applied in stretch spinning, rayon manufacturing, single-component polyester rayon, etc., and can solve the problems of flat yarn slitting surface damage, flat yarn temperature unevenness, heat transfer efficiency, etc. Low-level problems, to achieve the effect of improving melt strength and toughness, reducing crystallization, and preventing brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

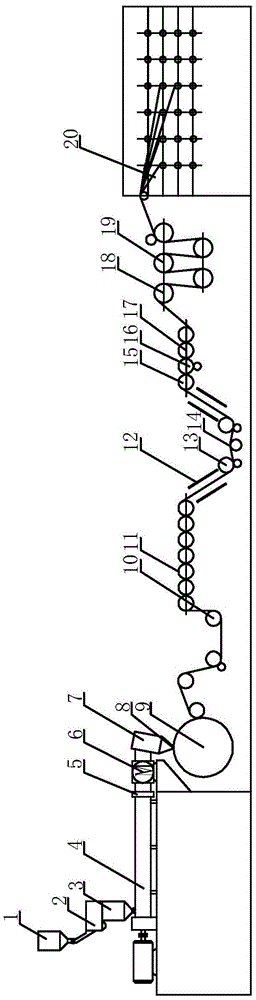

Image

Examples

Embodiment 1

[0026] (1) Mix PET polyester bag-packed basic slices and additives in a high-speed mixer according to a certain ratio, and send them to the slice hopper 1 by the vacuum conveying system for use in the crystallizer 2, and the slices fall into the crystallizer by their own weight. The crystallizer is heated with hot air at 140° C., and the residence time of the chips in the crystallizer 2 is 20 minutes. The pre-crystallized slices are continuously and evenly fed into the drying tower 3, and the slices are further dehydrated and dried with hot air at 160°C in the drying tower 3. The time is about 5 hours. After drying, the moisture content of the slices is 25ppm. The chips enter the parallel twin-screw extruder 4. The above-mentioned additives are toughening agent MG-801 (a vinyl elastomer bifunctionalized with acrylate and glycidyl ester, provided by Hangzhou Qitai Plastic Material Co., Ltd.), antioxidant IRGANOX1010 (tetra[β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionic acid]...

Embodiment 2

[0033](1) Mix PET polyester bagged basic slices and additives in a high-speed mixer according to a certain ratio, and send them to the slice hopper by the vacuum conveying system for use in the crystallizer, and the slices fall into the crystallizer by their own weight. The crystallizer is heated with hot air at 130° C., and the residence time of the chips in the crystallizer is 20 minutes. The pre-crystallized slices are continuously and evenly fed into the drying tower, and the slices are further dehydrated and dried with hot air at 180°C in the drying tower for about 4.5 hours. The moisture content of the slices after drying is 30ppm, and the slices after drying enter the parallel twin-screw extruder. The above-mentioned additives are toughening agent MG-801 (a vinyl elastomer bifunctionalized with acrylate and glycidyl ester, provided by Hangzhou Qitai Plastic Material Co., Ltd.), antioxidant IRGANOX168 (tris(2,4-diphosphite) tert-butylphenyl) ester, Zhejiang Jinhai Chemi...

Embodiment 3

[0040] (1) Mix PET polyester bagged basic slices and additives in a high-speed mixer according to a certain ratio, and send them to the slice hopper by the vacuum conveying system for use in the crystallizer, and the slices fall into the crystallizer by their own weight. The crystallizer is heated with hot air at 150°C, and the residence time of the chips in the crystallizer is 20 minutes. The pre-crystallized slices are continuously and evenly fed into the drying tower, and the slices are further dehydrated and dried with hot air at 170°C in the drying tower for about 4 hours. The moisture content of the slices after drying is 35ppm, and the slices after drying enter the parallel twin-screw extruder. The above-mentioned additives are toughening agent MG-801 (a vinyl elastomer bifunctionalized with acrylate and glycidyl ester, provided by Hangzhou Qitai Plastic Material Co., Ltd.), antioxidant IRGANOX168 (tris(2,4-diphosphite) tert-butylphenyl) ester, Zhejiang Jinhai Chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com