Propylene polymer and preparation method thereof

A technology of propylene polymer and polypropylene polymer, which is applied in the field of propylene polymer and its preparation, can solve the problems of polymer molecular weight decrease, brittleness, catalyst activity decrease, etc., and achieve good stereospecificity and high hydrogen sensitivity , the effect of high polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

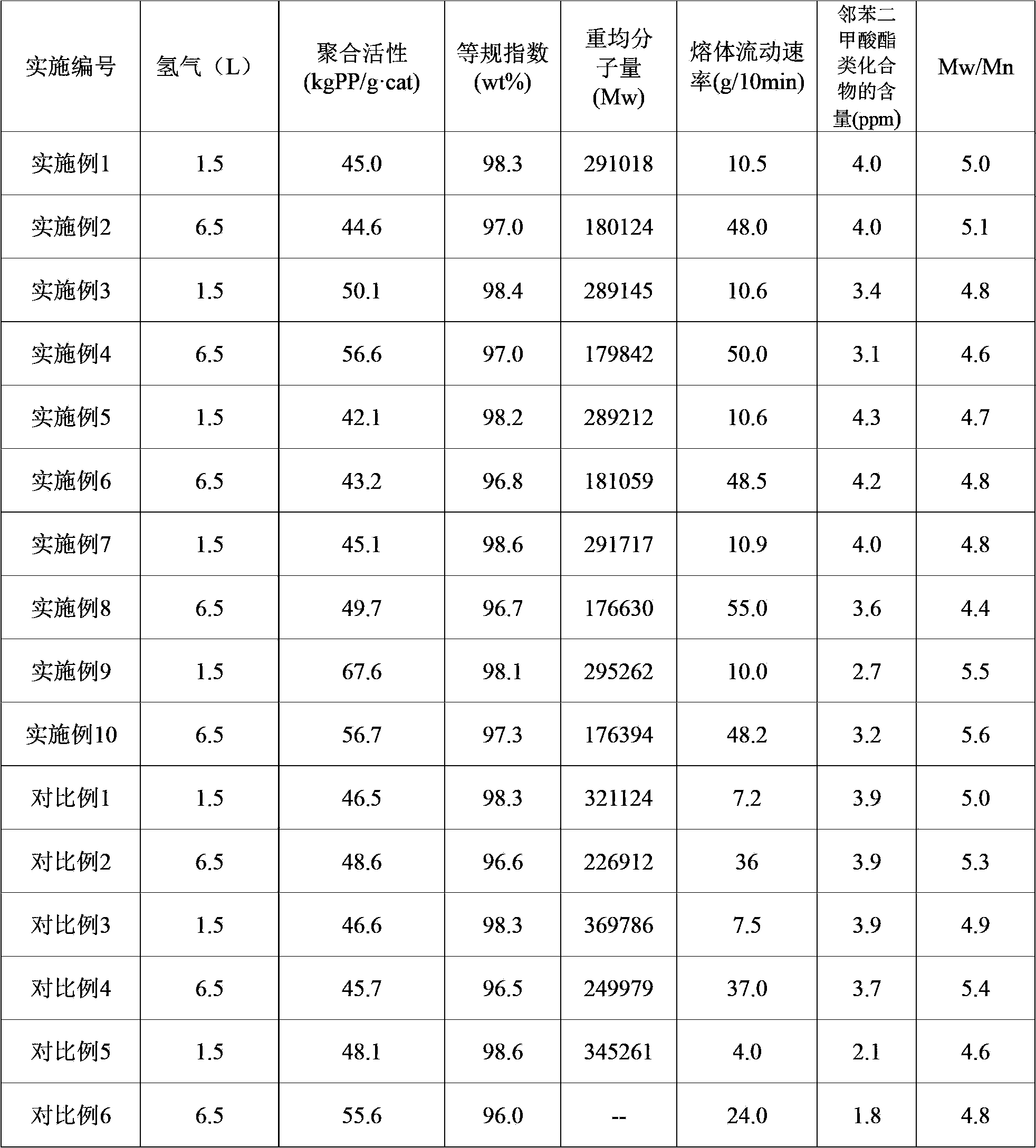

Examples

preparation example Construction

[0024] According to the preparation method of propylene polymer of the present invention, the method comprises polymerizing propylene or a mixture of propylene and ethylene and / or α-olefin under olefin polymerization conditions in the presence of a catalyst to obtain a propylene polymer, the catalyst Containing a solid component, an alkylaluminum compound and an external electron donor compound, the solid component comprising magnesium, titanium, halogen and an internal electron donor compound, the internal electron donor compound comprising a phthalate compound, Wherein, the solid component is prepared by the following method:

[0025] (1) reacting the magnesium-containing support with the first titanium compound, and adding an internal electron donor during one or more time periods before, during and after the reaction of the magnesium-containing support with the first titanium compound;

[0026] (2) The product obtained in step (1) is subjected to solid-liquid separation, a...

preparation example 1

[0069] This preparation example is used to prepare the catalyst solid component used in the preparation method of the propylene polymer of the present invention.

[0070] (1) Preparation of magnesium-containing carrier

[0071] In a 1.6L reactor, add 200ml white oil, 8.0g (0.08mol) magnesium chloride, 3g (0.01mol) octadecyl alcohol, 95ml (1.6mol) ethanol, 9.8ml (0.08mol) 2,2-dimethoxy base propane, heated to 90°C with stirring. After constant temperature reaction for 1 hour, the mixture was stirred (400 rpm) for 30 minutes to disperse for emulsification. Add 35ml (0.45mol) of epichlorohydrin to the above emulsified product, react for half an hour and press filter for 9 minutes. The press-filtered product was washed 5 times with hexane, and press-filtered after each wash. The total time of the press-filtering process was 20 minutes. Finally, the product was vacuum-dried to obtain the magnesium-containing carrier Z1.

[0072] The average particle diameter (D50) of the magnesiu...

preparation example 2

[0076] This preparation example is used to prepare the catalyst solid component used in the preparation method of the propylene polymer of the present invention.

[0077] (1) Preparation of magnesium-containing carrier

[0078] In a 1.6L reactor, add 300ml of white oil, 8.0g (0.08mol) of magnesium chloride, 10.8g (0.04mol) of stearyl alcohol, 28ml (0.48mol) of ethanol, 1ml (0.008mol) of 2,2-dimethoxy base propane, heated to 100°C with stirring. After constant temperature reaction for 0.5 hours, the mixture was stirred (800 rpm) for 30 minutes to disperse for emulsification. And add 12.5ml (0.16mol) epichlorohydrin to the above emulsified product, react for 20 minutes and press filter, the filter press time is 10 minutes. The press-filtered product was washed 5 times with hexane, and press-filtered after each wash. The total time of the press-filtering process was 25 minutes. Finally, the product was vacuum-dried to obtain the magnesium-containing carrier Z2.

[0079] The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com