A crack dissipative layer of micro-asphalt gravel based on vibration forming and its forming method

A technology of asphalt gravel and vibration forming, which is applied in the field of road engineering, can solve the problems of difficulty in controlling the construction time of pre-cutting joints in the base, poor suppression of large cracks, and increasing the thickness of asphalt surface layers, so as to reduce maintenance costs and improve road quality. Use performance, the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0018] The micro-asphalt macadam crack dissipating layer based on vibration test method of the present invention, its specific steps are:

[0019] (1) Selection of raw materials:

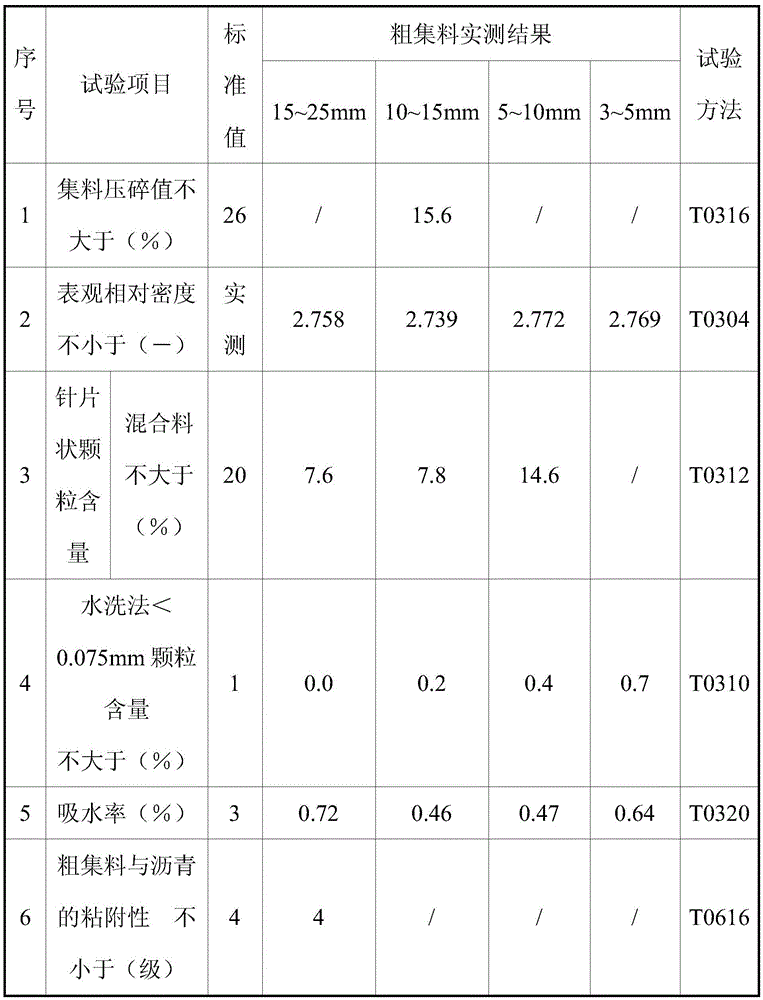

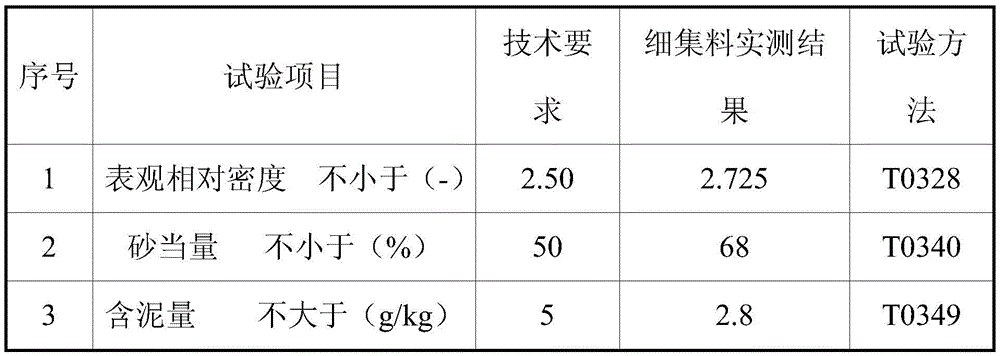

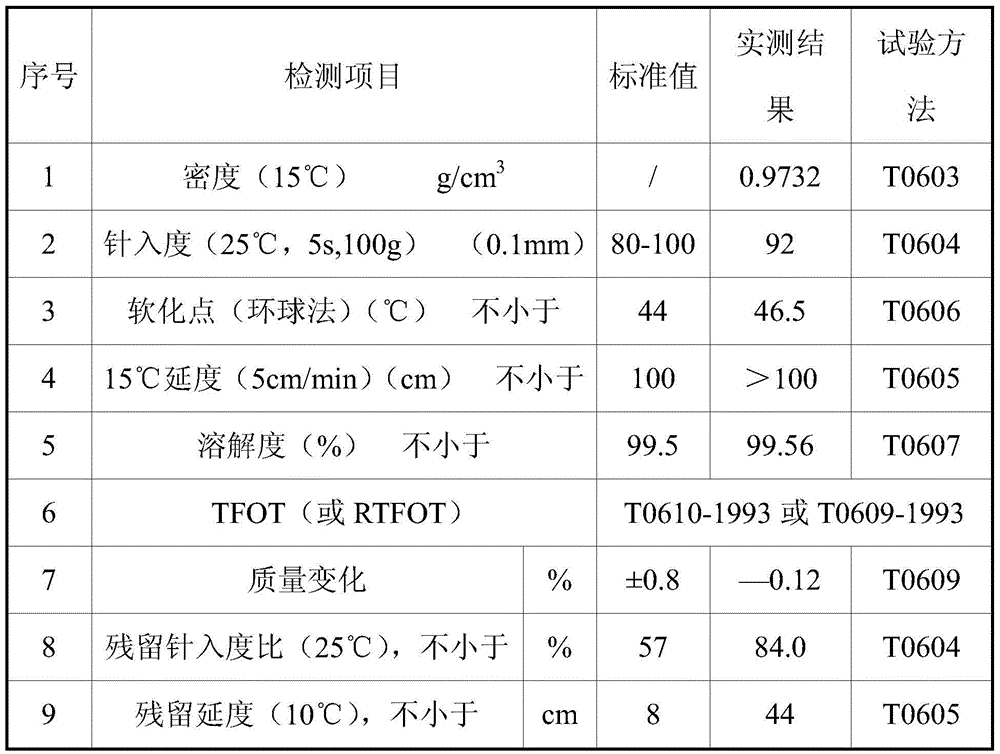

[0020] Select the raw material for the fracture dissipative layer of micro-asphalt gravel: limestone is used as the mineral material for the crack dissipative layer. Coarse aggregates in limestone have certain toughness, and the cohesion between limestone and asphalt is good; fine aggregates have certain plasticity, good construction workability, easy rolling and forming, and not easy to segregate; Impact crusher rolling, the technical parameters of coarse aggregate are shown in Table 1, and the technical parameters of fine aggregate are shown in Table 2. Asphalt is selected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com