Method of treating wastewater by catalyzing ozone to oxidize by using pyrite cinder

A pyrite slag and ozone oxidation technology, which is applied in the field of water treatment, can solve the problems of large dosage of ozone, low mineralization rate of organic matter, and insufficient ozone oxidation ability, and achieve low economic cost, stable properties, and reduced The effect of preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Catalyst preparation: sieve pyrite slag to obtain slag particles with a particle size of 100-200 mesh, and sieve out particles with too large or too small particle sizes to obtain slag particles with uniform particle size; Add 100g of slag to 0.3L containing 0.1mol / L H 2 o 2 In acidic aqueous solution (pH 4), the solid-to-liquid ratio is about 1 ∶ 3. Slowly stir and wash for 3 hours, then settle for 1 hour and then separate the solid and liquid, and dry the obtained slag at 50°C for 4 hours; soak the dried slag in 0.5mol / L NaHCO 3 In the solution, the solid-to-liquid ratio was 1:2. After 20 hours, the supernatant was poured out, and the slag was dried at room temperature for later use.

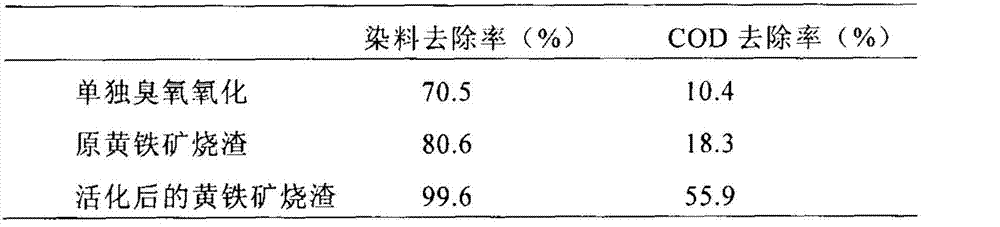

[0027] Catalytic ozonation treatment of simulated dye wastewater: the experiment was divided into three parallel samples, and 2L of simulated wastewater containing active black 5 with an initial concentration of 100mg / L was added to the three reactors (pH=7.0, COD 0 =54.6mg / L), no ca...

Embodiment 2

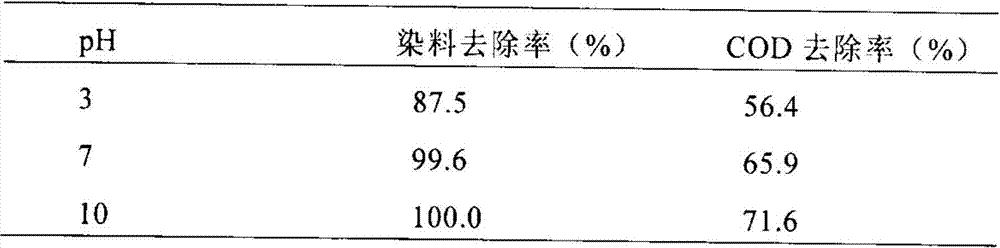

[0031] In 2L of simulated wastewater containing active black 5 with an initial concentration of 100mg / L, the initial pH values were 3.0, 7.0, and 10.0, respectively (COD 0 =54.6mg / L), add 2.5g / L activated pyrite slag (prepared according to the method in Example 1), feed 2mg / min of ozone at room temperature, and the reaction time is 1h. The dosage is 40mg / L, record the concentration and COD value of activated black 5 after treatment, and the effect of ozone oxidation treatment using activated pyrite slag as catalyst is shown in the table below, which shows that pyrite slag catalyzes ozone oxidation It has a relatively wide pH range.

[0032] Table 2 Catalytic ozone oxidation of pyrite slag under different pH conditions in the treatment of reactive black 5 simulated dye wastewater

[0033]

Embodiment 3

[0035] Catalyst preparation: sieve pyrite slag to obtain slag particles with a particle size of 100-200 mesh. Add 100g of the sieved slag to 0.5L of H containing 0.4mol / L 2 o 2Acidic aqueous solution (pH 4) was stirred and washed at a slow speed for 5 hours, the solid-liquid ratio was about 1:5, and then the solid-liquid separation was carried out after static precipitation for 1 hour, and the obtained slag was dried at 50°C for 4 hours; the dried slag was dried Soak the slag in 0.8mol / L NaHCO 3 After 24 hours in the solution, the solid-to-liquid ratio was 1:1, the supernatant was poured out, and the slag was dried at room temperature for later use.

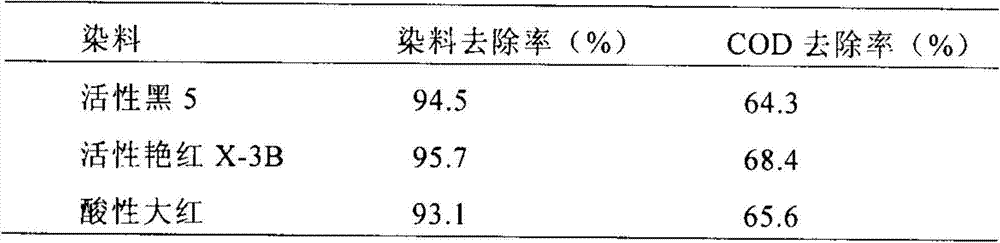

[0036] Catalytic ozonation treatment of simulated dye wastewater: 2L of simulated wastewater containing reactive black 5, reactive brilliant red X-3B, and acid scarlet with an initial concentration of 200mg / L at an initial pH value of 7.0 (COD 0 109.34mg / L, 112.23mg / L, 102.57mg / L), add 5g / L activated pyrite slag, inject 2mg / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com