Molecular sieve production apparatus

A molecular sieve and equipment technology, applied in the field of equipment for preparing molecular sieves, can solve the problems of difficulty in improving, unfavorable harm, device blockage, etc., and achieve the effects of stable product performance, low labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

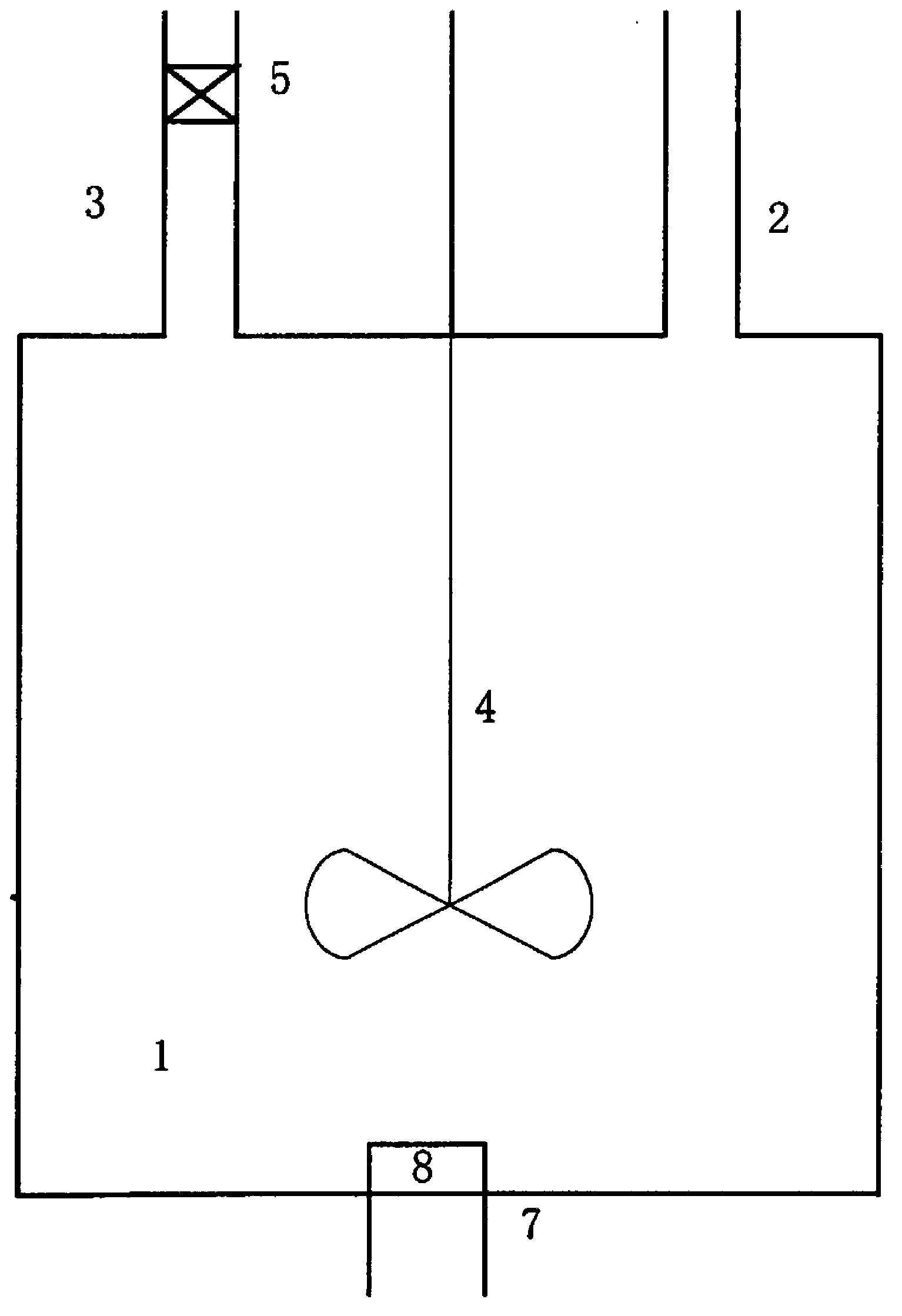

[0028] In the method for preparing molecular sieves provided by the present invention, the molecular sieves are continuously introduced into the gas-phase ultra-stable reactor, and the molecular sieves are continuously moved from the molecular sieve inlet to the molecular sieve outlet without carrier gas transportation, and are combined with the gas-phase ultra-stable reactor. Silicon tetrachloride gas contact for ultra-stabilized reaction. Simultaneously, silicon tetrachloride was continuously introduced into the reactor.

[0029] In the method for preparing molecular sieves provided by the present invention, silicon tetrachloride can be introduced into the reactor in a liquid phase and then vaporized in the reactor and reacted with the molecular sieve, but in order to make the reaction uniform, it is preferred that silicon tetrachloride is vaporized and then introduced into the gas phase stabilized in the reactor. The molecular sieve and vaporized silicon tetrachloride are ...

Embodiment 1

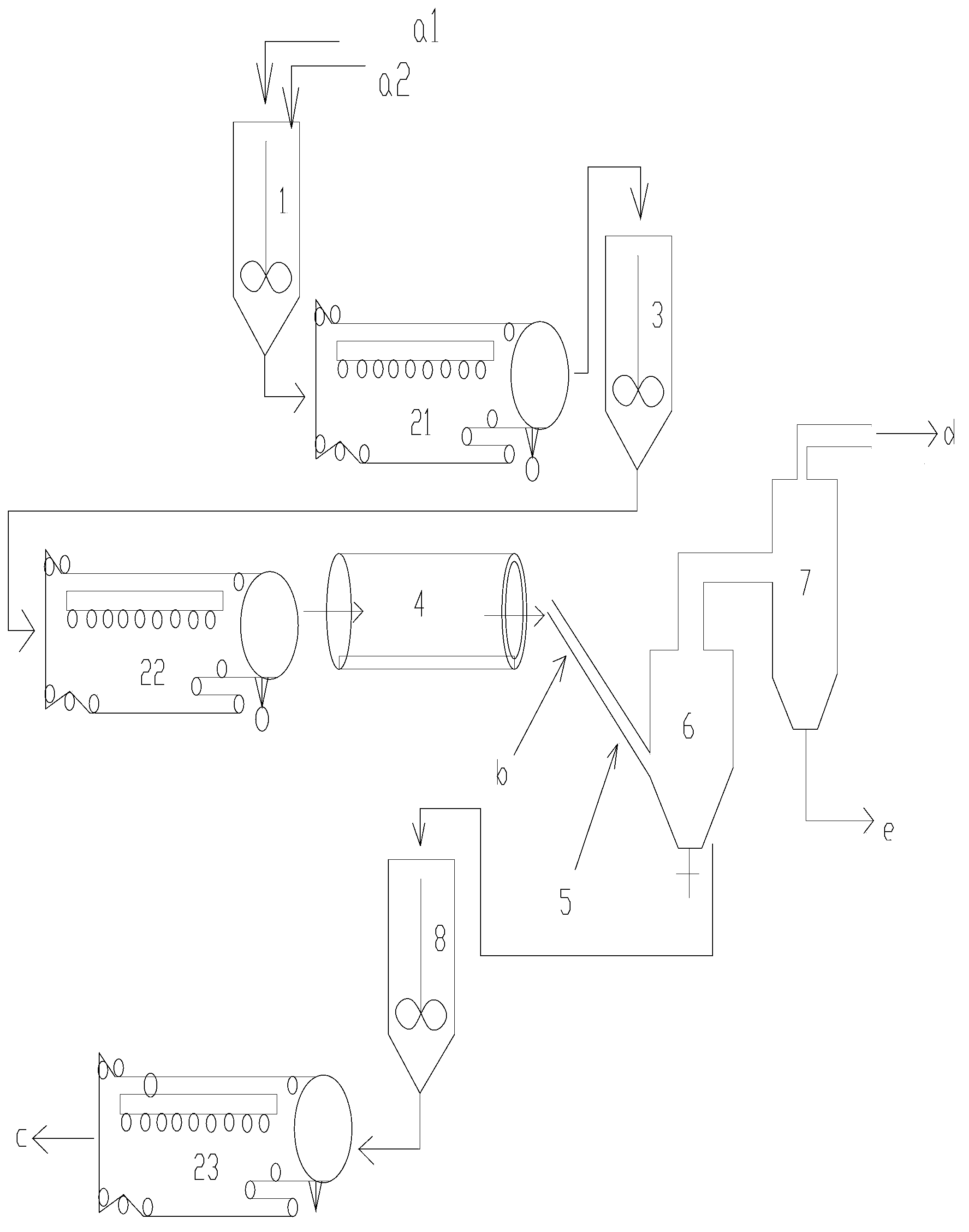

[0067] Made of industrial grade stainless steel with a thickness of 3mm NiCr18Ti figure 2 In the molecular sieve gas-phase silicon replenishment equipment shown, the upper part of the gas-solid separator 6 is cylindrical with a diameter of 6 meters and a height of 14 meters, and the lower part is conical with an opening with a cone angle of 45°, and a valve is provided at the opening , the outlet is located at a position 1 meter away from the top of the gas-solid separator, and the absorption tower 7 is filled with an aqueous sodium hydroxide solution with a concentration of 10 mol / liter. The absorption tower 7 and the gas-solid separator 6 are connected by a conduit, and the conduit goes deep into the Sodium hydroxide aqueous solution.

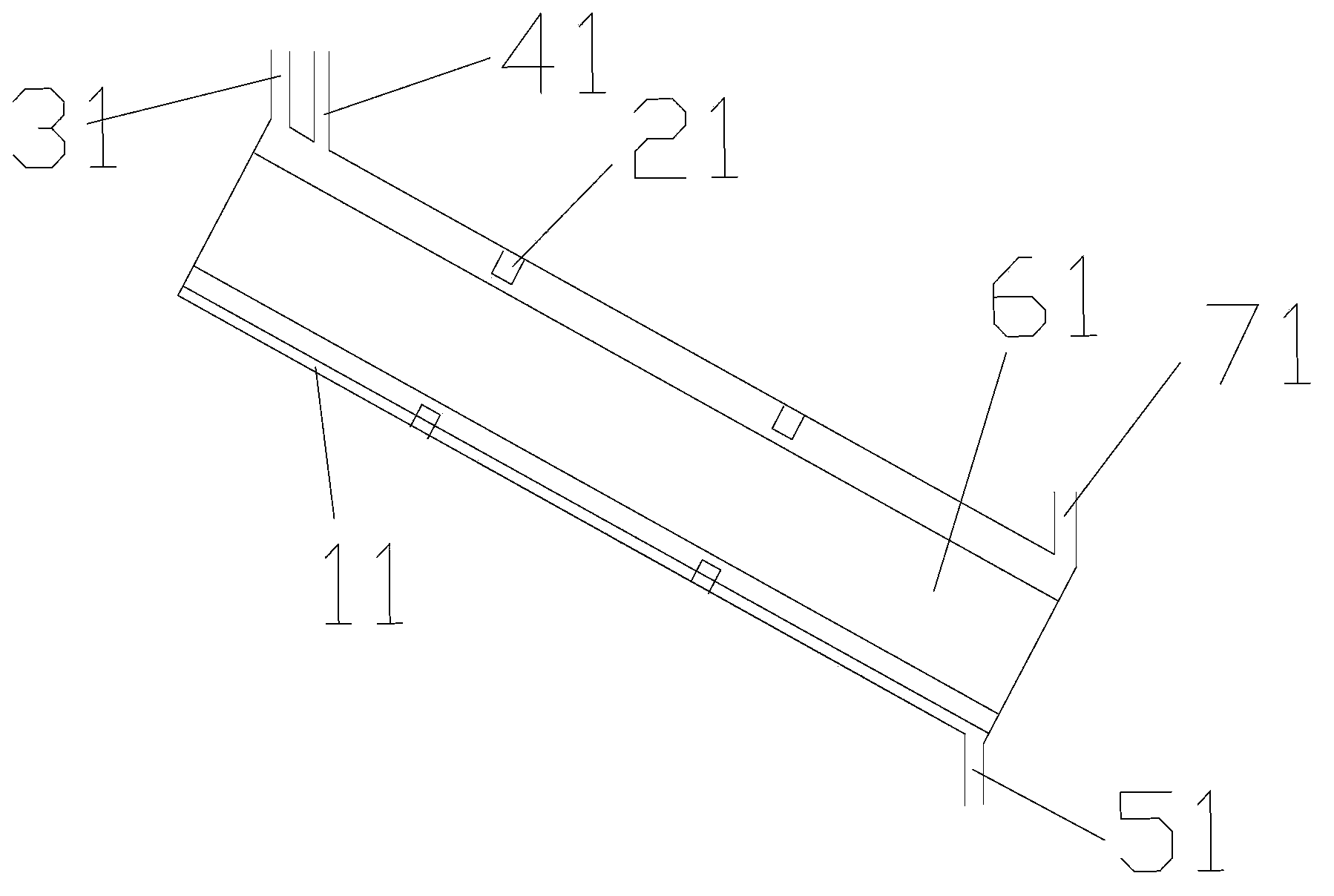

[0068] Reactor 5 is a tubular reactor, such as Figure 5 As shown, the total length of the pipe body is 80 meters, and the diameter of the pipe body is 0.8 meters. The pipe body of the reactor is made into a ring. The reactor includes an up...

Embodiment 2

[0071] Made of industrial grade stainless steel with a thickness of 3mm NiCr18Ti figure 2 In the molecular sieve gas-phase silicon replenishment equipment shown, the upper part of the gas-solid separator 6 is cylindrical with a diameter of 6 meters and a height of 14 meters, and the lower part is conical with an opening with a cone angle of 45°, and a valve is provided at the opening , the outlet is located at a position 1 meter away from the top of the gas-solid separator, and the absorption tower 7 is filled with an aqueous sodium hydroxide solution with a concentration of 10 mol / liter. The absorption tower 7 and the gas-solid separator 6 are connected by a conduit, and the conduit goes deep into the Sodium hydroxide aqueous solution.

[0072] The pipe body of the tubular reactor is 60 meters in length and is a straight pipe. The angle between the axis of the pipe reactor and the horizontal plane is 45°, and the diameter (inner diameter) of the pipe body is 1 meter, such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com