Pulp egg support full-automatic production line

A fully automatic, production line technology, used in progressive dryers, drying solid materials, loading/unloading, etc., can solve the problems of inconvenient operation, low automation, low production efficiency, etc., and achieve simple operation and low investment cost. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

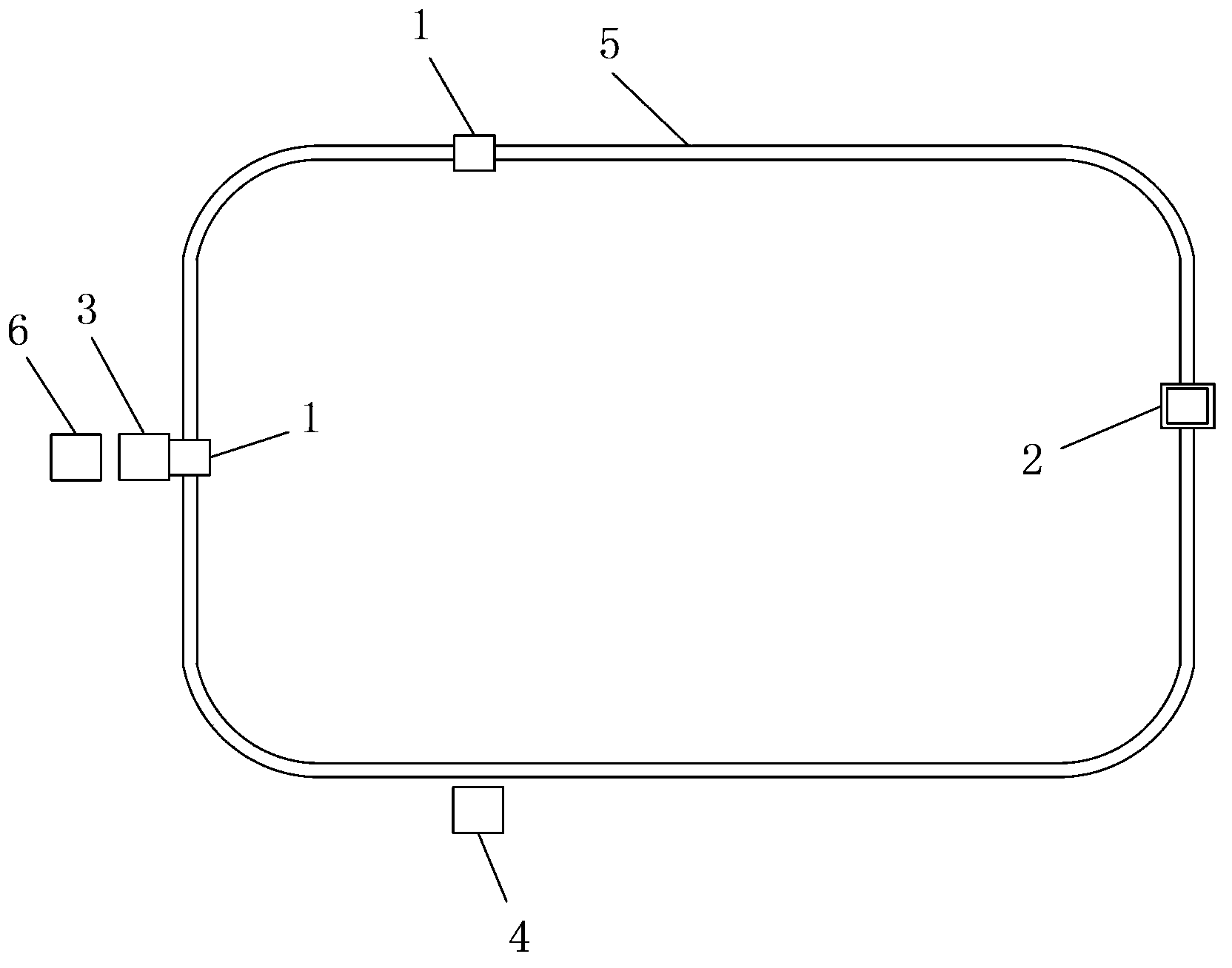

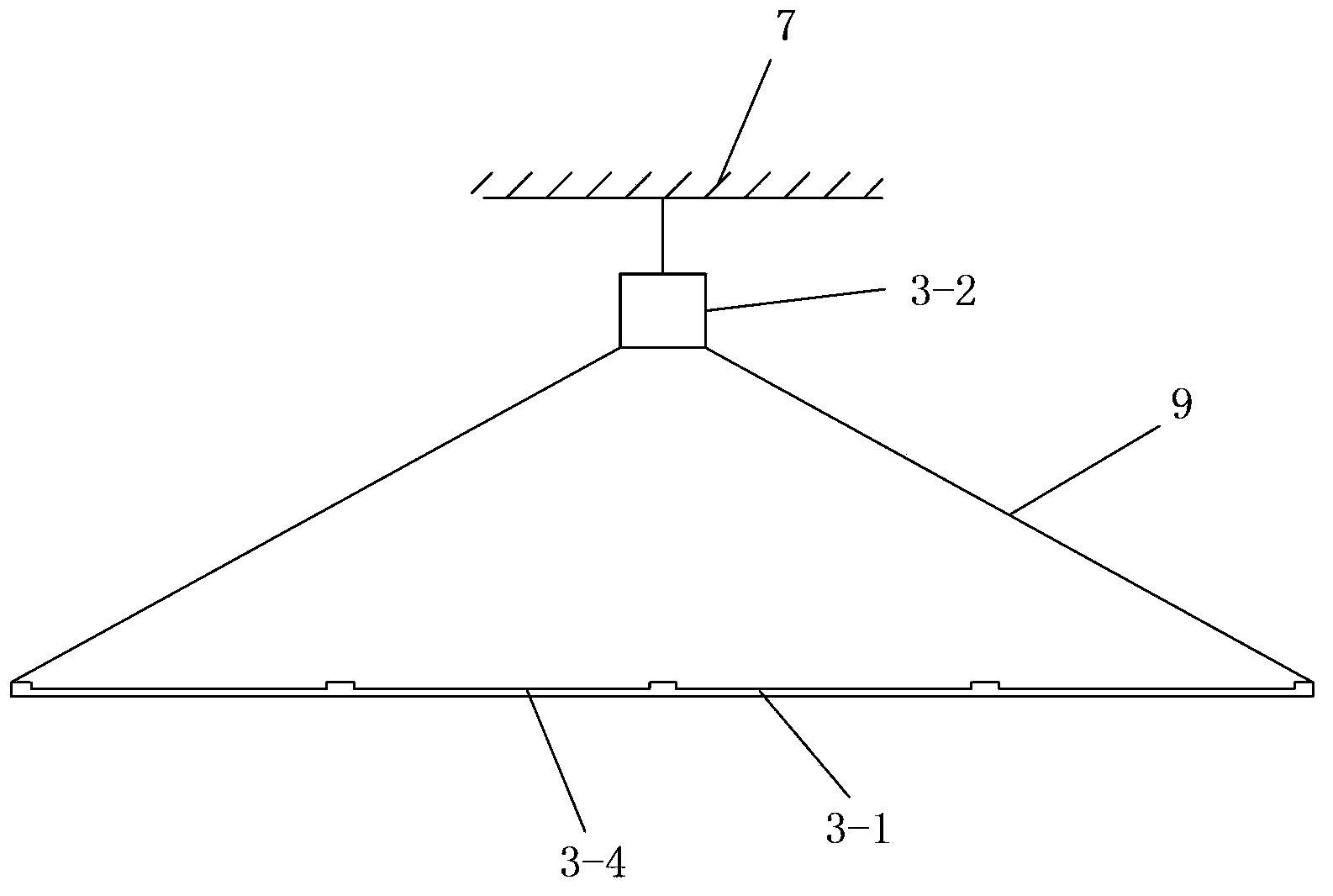

[0051] Such as figure 1 , Figure 7 As shown, the present invention includes an electric transport vehicle 1, a circular moving track 5 for the electric transport vehicle 1 to move, a loading system 3 that automatically loads the pulp egg tray formed by the egg tray molding machine 6 into the electric transport vehicle 1, and the electric transport vehicle 1. An oven 2 for automatically drying the compressed pulp egg trays mounted on the transport vehicle 1 and an unloading system 4 for unloading the dried pulp egg trays from the electric transport vehicle 1 . Both the loading system 3 and the unloading system 4 are arranged outside the circular moving track 5 , and the loading system 3 is arranged on one side of the egg tray forming machine 6 .

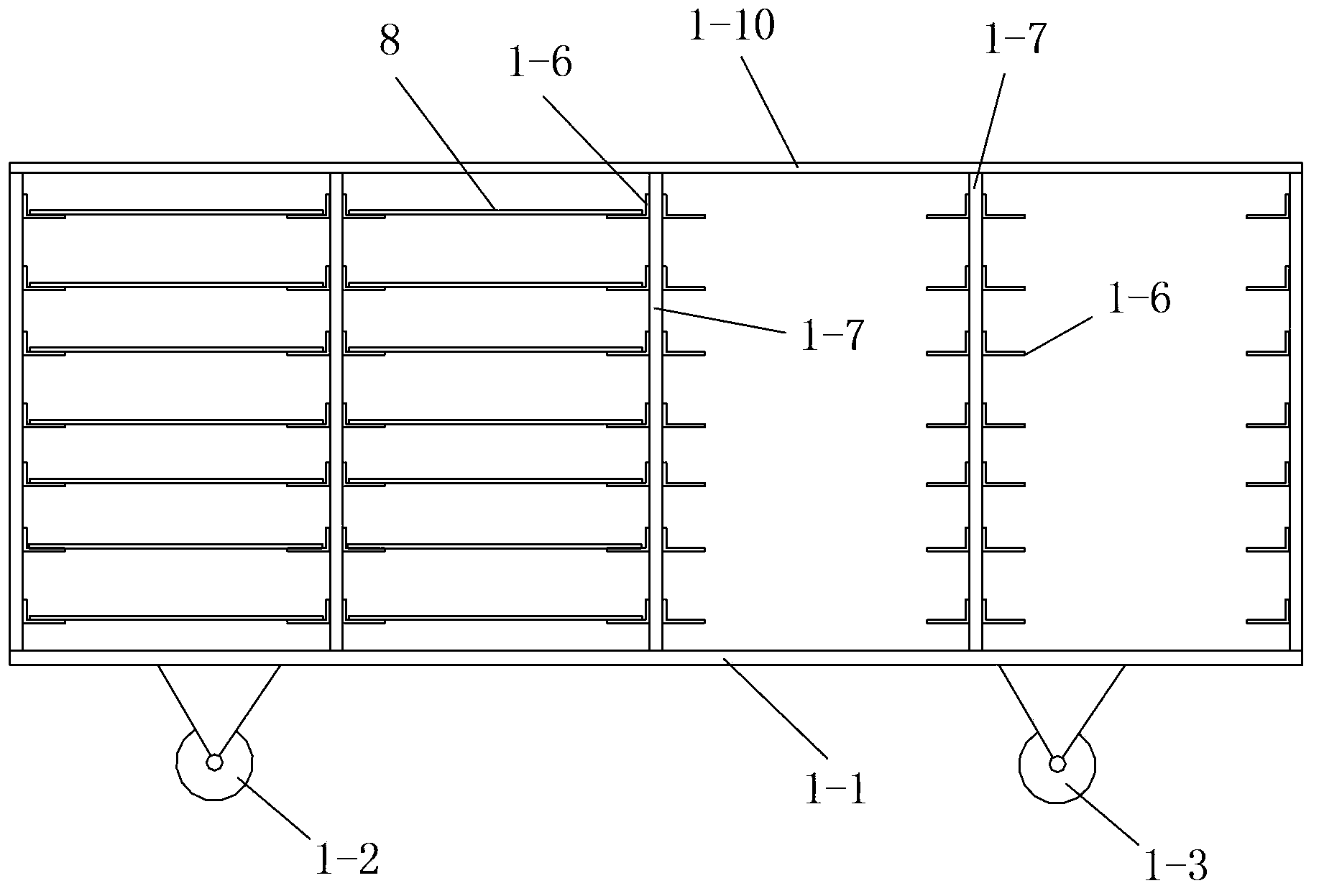

[0052] to combine figure 2 , the electric transport vehicle 1 includes a vehicle frame 1-1, a metal bracket installed on the vehicle frame 1-1 and a walking mechanism installed on the vehicle frame 1-1, and the walking mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com