Catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of low yield of low-carbon olefins and achieve good selectivity of low-carbon olefins and excellent hydrothermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the phosphorus-modified β molecular sieve of the present invention comprises that the raw powder of the β molecular sieve (sodium type β molecular sieve containing an organic template) is passed through at least two different The overlapping temperature range treatment is obtained by removing the template agent and then performing phosphorus modification. More specifically, it includes the following steps:

[0023] (1) The sodium-type β molecular sieve is exchanged with ammonium to make the Na on the molecular sieve 2 The O content is less than 0.2% by weight;

[0024] (2) After drying the molecular sieve obtained in step (1), treat it at a temperature range of 200-400°C for at least 0.5 hours, and then heat it up to a temperature range of 500-800°C within at most 2 hours and treat it for at least 0.5 hours to remove the template agent;

[0025] (3) Introducing phosphorus-containing compounds to modify molecular sieves;

[0026] (4) Baking ...

preparation Embodiment 1

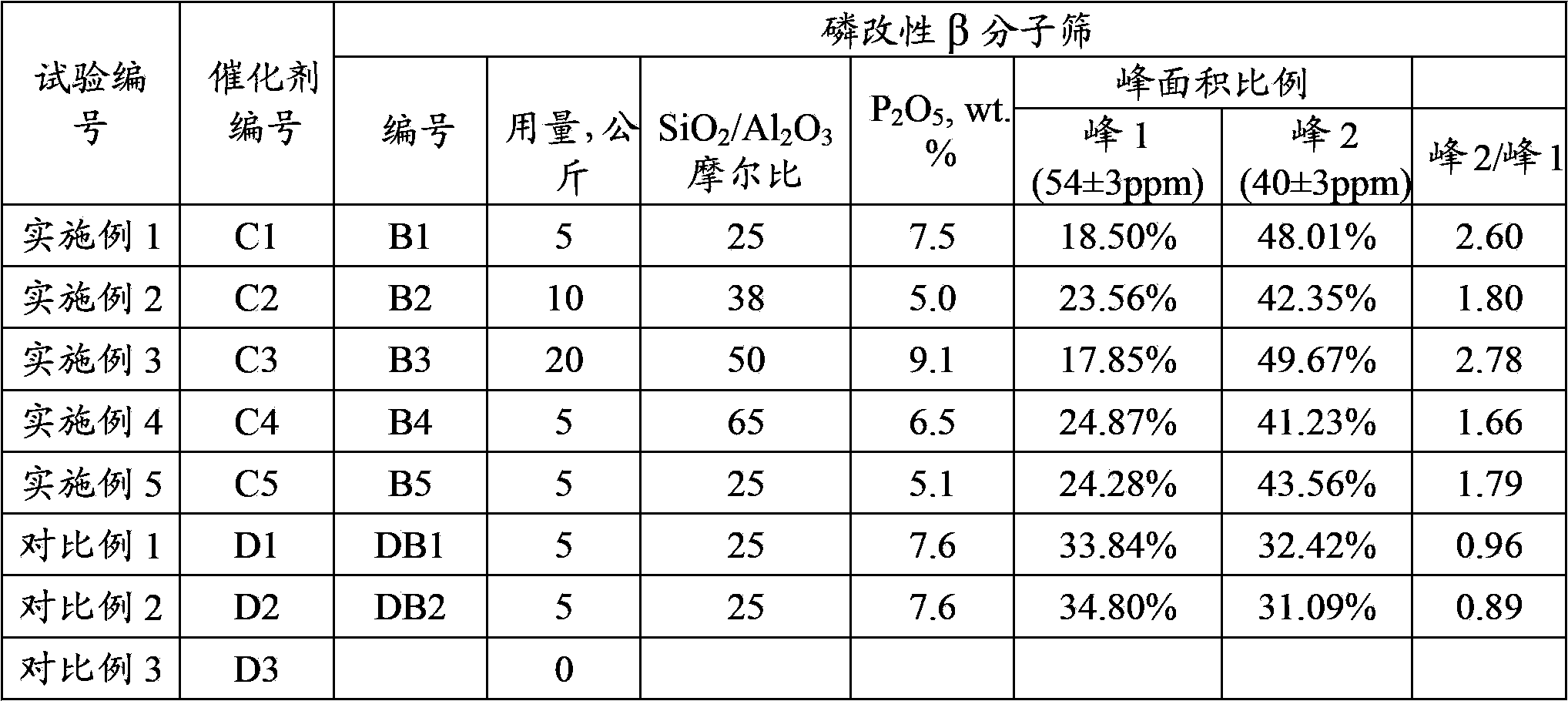

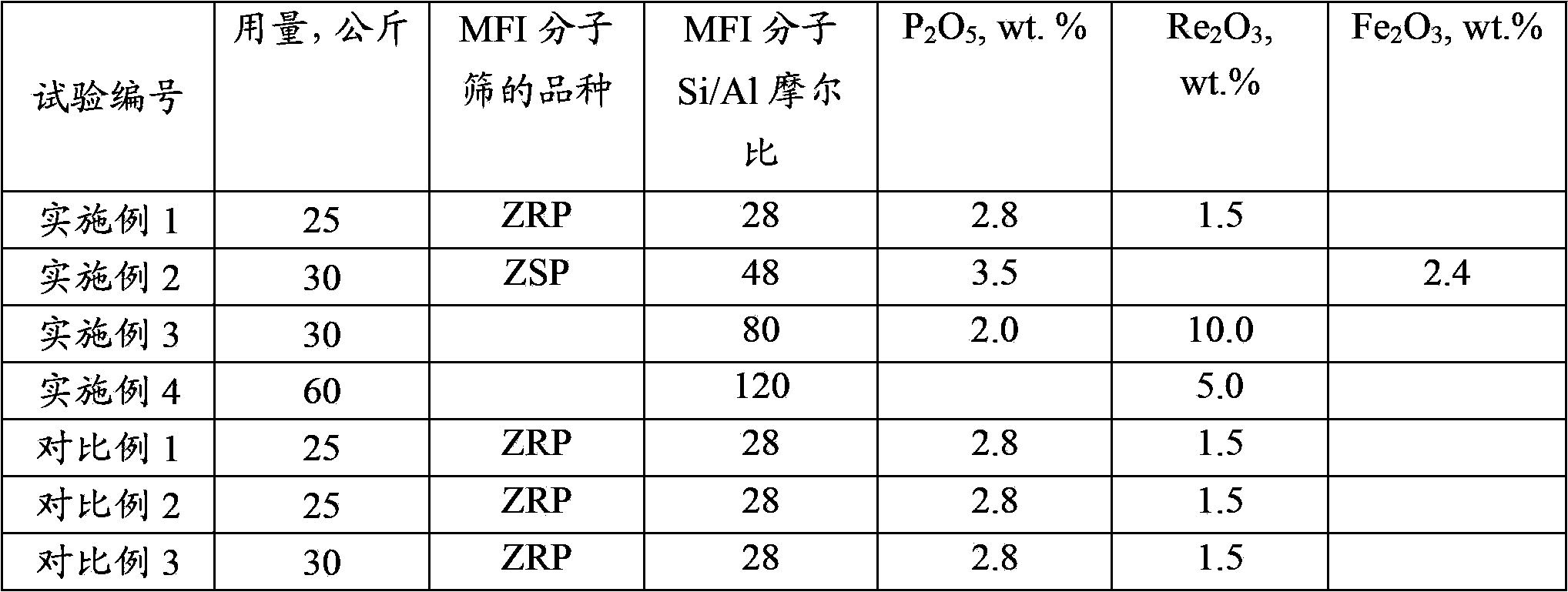

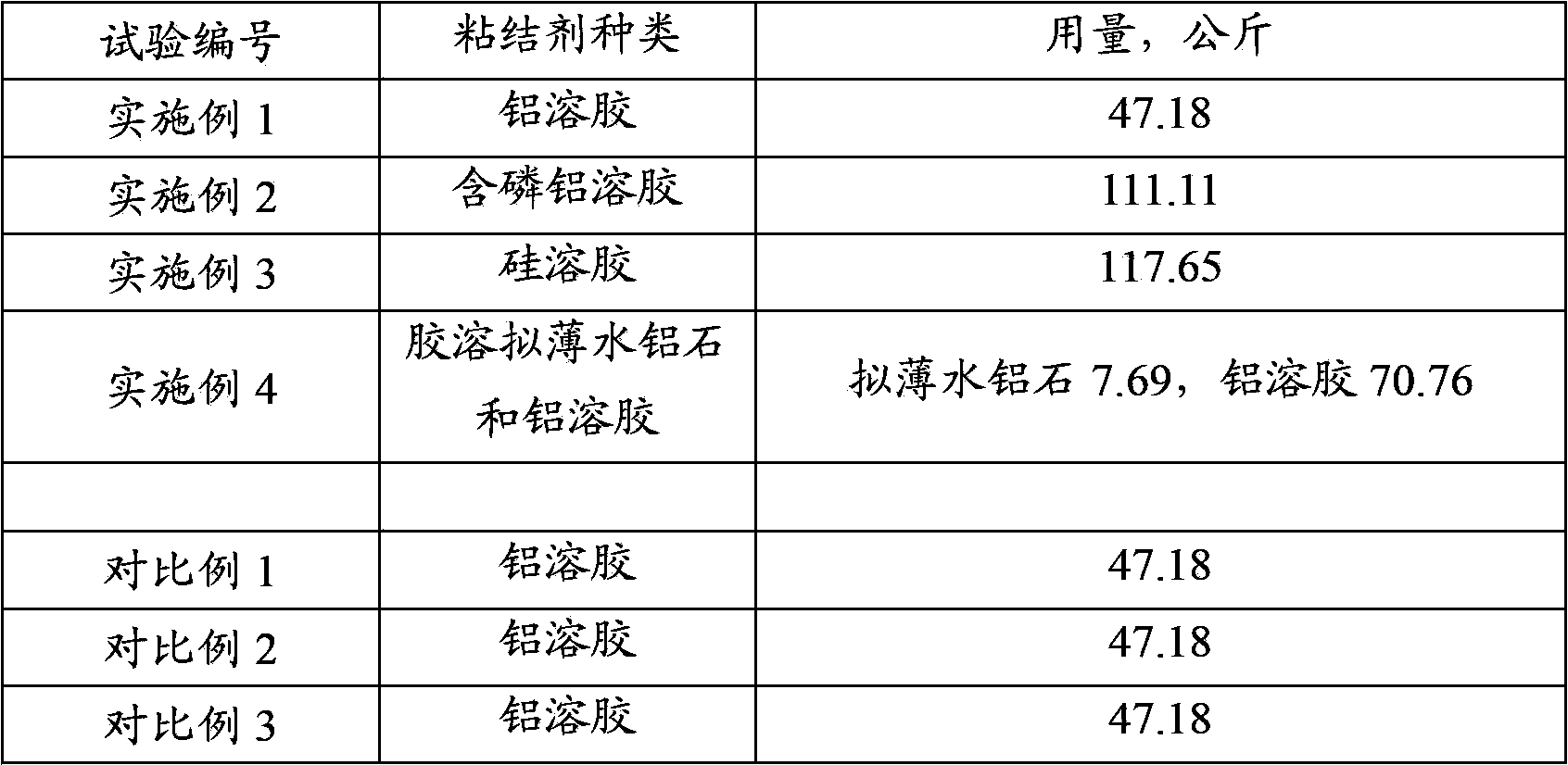

[0037] Naβ molecular sieve (produced by Qilu Catalyst Factory, SiO 2 / Al 2 o 3 =25 molar ratio, sodium oxide content 4.5% by weight, the same below) with NH 4 Cl solution exchange wash to Na 2 The O content is lower than 0.2% by weight, and the filter cake is obtained by filtration; dried, and the obtained sample is calcined at 350°C for 2 hours, then heated (heating rate 5°C / min) to 550°C, and calcined for 4 hours to remove the template agent; add 14.6 kgH 3 PO 4 (concentration 85% by weight) was dissolved in 90 kg of water, mixed with 100 kg of the above-mentioned roasted molecular sieve, impregnated and dried; the obtained sample was roasted at 500°C for 2 hours, that is, the molecular sieve provided by the present invention, denoted as B1. The physical data of the samples and 27 Al MAS NMR peak area ratios are listed in Table 1.

preparation Embodiment 2

[0039] Naβ molecular sieve (produced by Qilu Catalyst Factory, SiO 2 / Al 2 o 3 =25) with NH 4 Cl solution exchange wash to Na 2 The O content is lower than 0.2% by weight, and the filter cake is obtained by filtration; dried, and the obtained sample is roasted at 350°C for 2 hours, then heated to 550°C for 4 hours in 30 minutes to remove the templating agent; add 9.6 kg (NH 3 ) 2 HPO 4 (concentration 85% by weight) dissolved in 90 kg of water, mixed with 100 kg of the above-mentioned roasted molecular sieve, impregnated and dried; the obtained sample was roasted at 550°C and 100% water vapor for 2 hours, that is, the molecular sieve provided by the present invention, denoted as B2 . The physical data of the samples and 27 Al MAS NMR peak area ratios are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com