Low-pressure injection pulse-jet bag dust collector

A bag-type dust collector and dust collector technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of low dust removal and filtration efficiency, dust attached to the filter bag, etc., and achieve light weight and reliable performance. , The effect of high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the technical scheme is further described as follows:

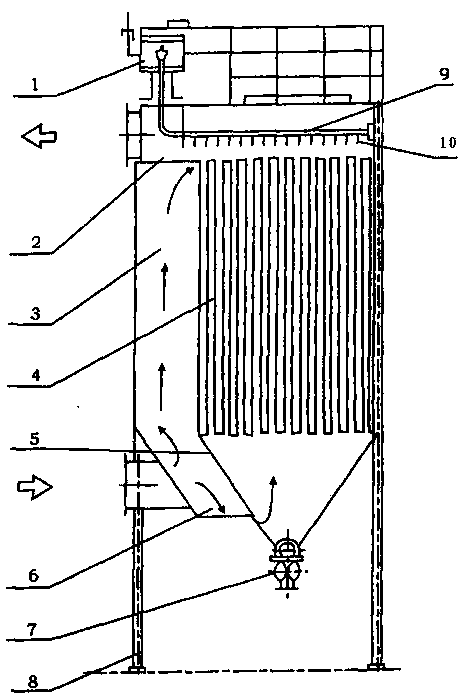

[0012] A new low-pressure injection pulse bag filter, which is characterized in that it includes one or more identical dust collector units, and the flue gas inlets and air outlets of each dust collector unit are connected respectively; device, upper box, middle box, filter bag, deflector, ash hopper and ash unloading device; there are multiple filter bags;

[0013] The upper box and the middle box are independent of each other, and they are separated by filter bags; the opening of each filter bag faces upward, and the opening end of the filter bag is connected with the upper box, and the inner cavity of the filter bag is connected with the upper box; The bag body of the bag is in the middle box; the ash hopper is connected to the bottom of the middle box, and the bottom of the ash hopper is connected with an ash unloading device; the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com