Circuit-board manufacturing method

A circuit board manufacturing and circuit board technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit assembly of electrical components, etc., can solve problems such as difficult control of processing quality, pollution sources, skewed assembly of components, etc., to avoid waste of high-priced metals, The effect of reducing pollution sources and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

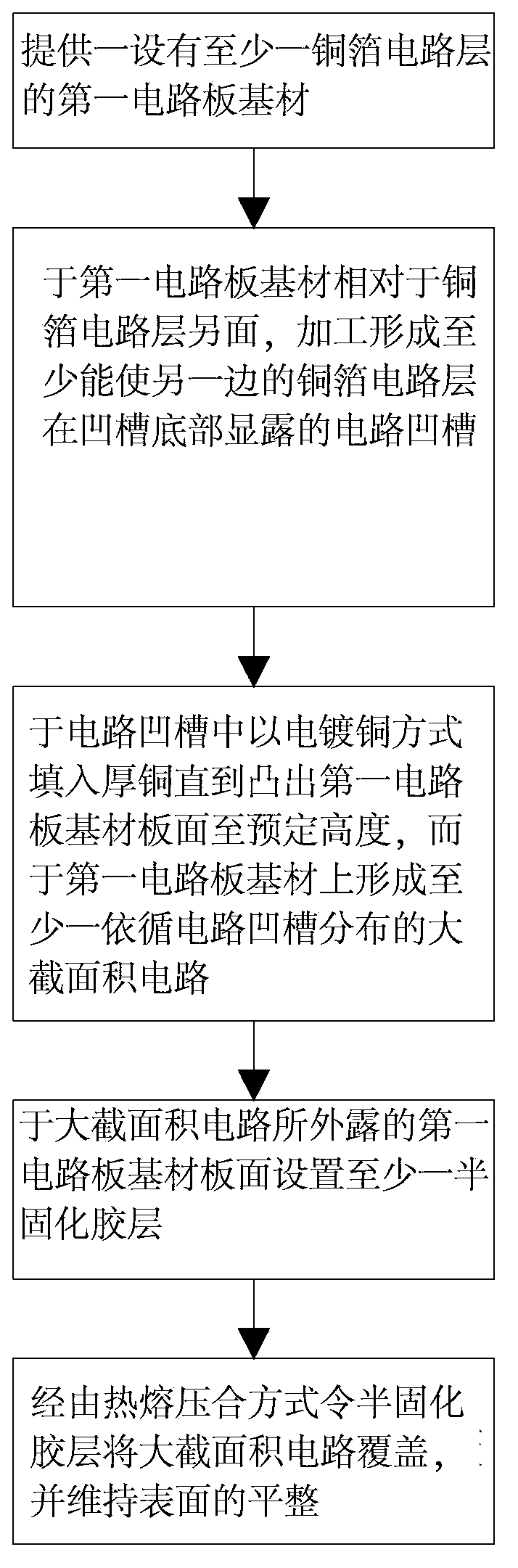

[0052] like figure 1 As shown in the basic flow chart of the present invention, the circuit board manufacturing method of the present invention basically includes the following steps.

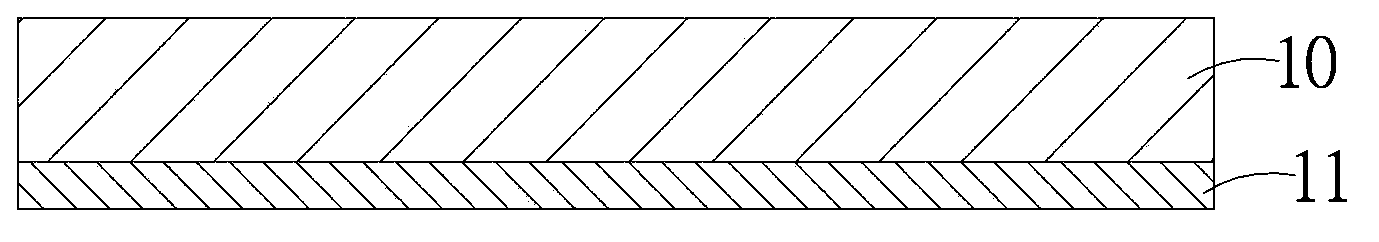

[0053] a. Provide as figure 2 The shown first circuit board substrate 10 is provided with at least one copper foil circuit layer 11; during implementation, the first circuit board substrate 10 may be provided with a copper foil circuit layer 11 on one of its surfaces, or may be provided on two surfaces. Each board surface is provided with a copper foil circuit layer.

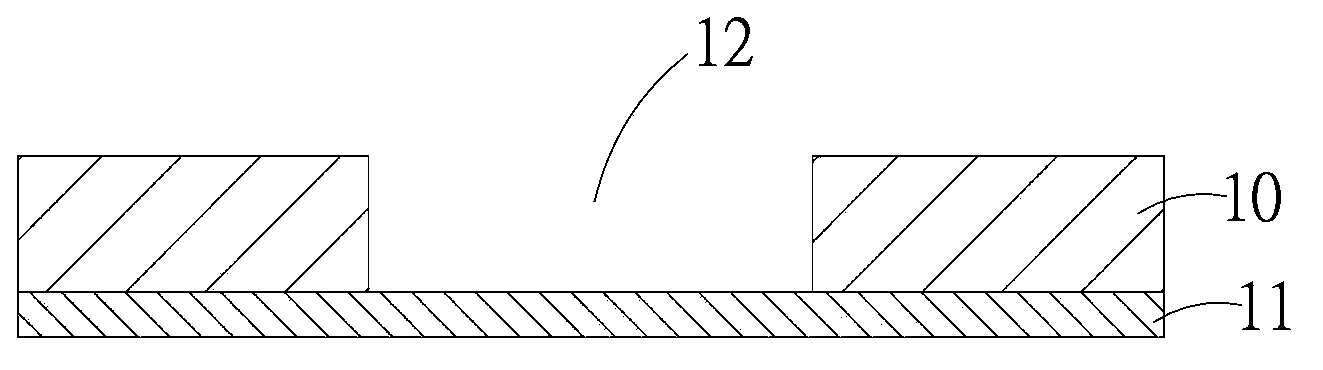

[0054] b. On the other side of the first circuit board substrate 10 relative to the copper foil circuit layer 11 (as shown in the figure, the other side of the first circuit board substrate 10 relative to the copper foil circuit layer 11 ), processing to form at least the The circuit groove 12 of the copper foil circuit layer 11 on the other side is exposed at the bottom of the groove.

[0055] c. If Figure 4 As shown, thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com