High dynamic response current control method and system for permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and current response, which is applied in the control system, vector control system, motor generator control, etc., can solve the problems of reducing the dynamic performance of predictive control, reduce the sensitivity of system parameters, shorten the control delay, The effect of maintaining system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

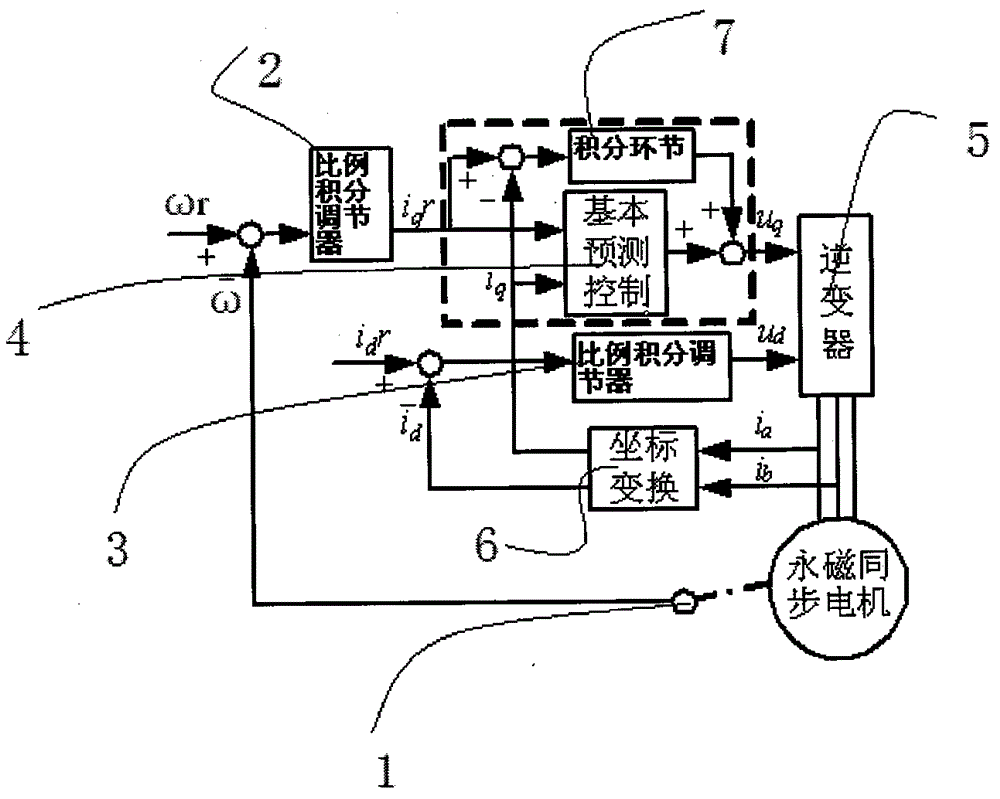

[0038] Such as image 3 , Figure 4 As shown, the high dynamic response current control method of the permanent magnet synchronous motor provided by the present invention includes the adjustment of the outer speed loop and the inner current loop adjustment. In terms of the q-axis, the motor speed is obtained through speed detection, compared with the speed command, and then sent After the input speed outer loop is adjusted, the speed outer loop outputs the q-axis current command iqr; as for the d-axis, since the id=0 control method is usually adopted, the d-axis current command idr is usually set to zero, and the two current commands iqr, idr is compared with the current feedback value iq and id of the corresponding axis and input to the corresponding current inner loop adjustment. After adjustment, the voltage uq and ud to be applied on the corresponding axis are respectively output. Such uq and ud voltages go through steps such as inverse coordinate transformation Calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com