Ground wire device and laying method

A laying method and technology of ground wires, applied in the direction of connecting contact materials, etc., can solve problems such as fire, electrical equipment tripping or damage, environmental corrosion grounding, etc., and achieve the effect of simple structure and improved grounding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

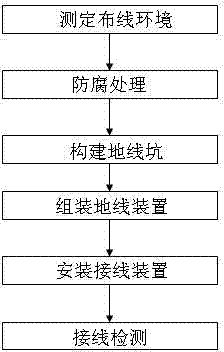

[0019] Embodiment 1: two ground wire devices with a length of 2 meters are laid vertically in advance, and its specific laying method is as follows:

[0020] Step 1: Determine the wiring environment. There are high-rise buildings at the laying point of the ground wire device and the high-rise building is equipped with a lightning rod system. The soil at the laying point is weakly alkaline and the content of metal minerals is negligible;

[0021] The second step: anti-corrosion treatment, spray epoxy resin anti-corrosion coating on the outer surface of the wire, sleeve, sealing ring and ground terminal for anti-corrosion treatment, and the sleeve is a PVC profile tube;

[0022] Step 3: Construct the ground pit, and construct the ground pit according to the number of ground wire devices and the environment of the laying point. The distance between the two ground pits is 5 meters, and the distance between the ground pit and the building is 4 meters, and the distance from the groun...

Embodiment 2

[0026] Embodiment two: Pre-lay two ground wire devices with a length of 2 meters vertically, and its specific laying method is as follows:

[0027] Step 1: Determine the wiring environment. The laying point of the ground wire device is open and there are no high-rise buildings and high-rise buildings and other electrical equipment. close to the road;

[0028] The second step: anti-corrosion treatment, spraying epoxy resin anti-corrosion coating on the outer surface of the wire, bushing, sealing ring and grounding terminal for anti-corrosion treatment, wherein the bushing is galvanized steel pipe;

[0029] The third step: construct the ground pit, and construct the ground pit according to the number of ground wire devices and the environment of the laying point, and the distance between the two ground pits is 5 meters;

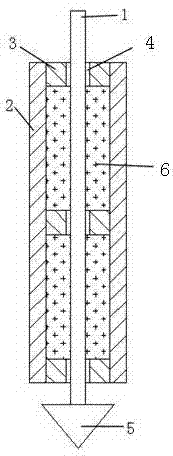

[0030] Step 4: Assemble the grounding wire device, assemble the anti-corrosion-treated wire, sleeve, sealing ring and grounding terminal, fill the sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com