Method for preparing graphene-based chip heat-radiating material

A chip heat dissipation and graphene technology, applied in the field of microelectronics, can solve the problems of poor horizontal and vertical heat dissipation of high-power chips, achieve the effects of inhibiting horizontal film growth, simple process, and low requirements for the preparation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]The invention provides a method for preparing a graphene-based chip heat dissipation material, and the preparation method of the graphene-based chip heat dissipation material at least includes the following steps:

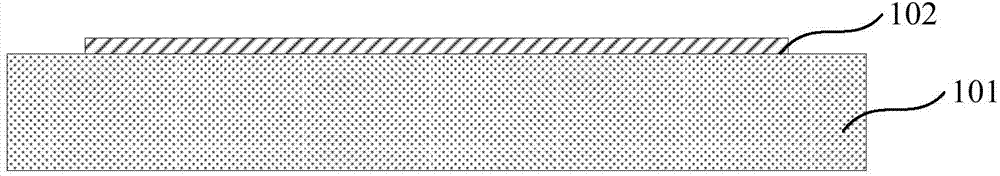

[0050] 1) Provide a substrate, and prepare horizontal graphene on the substrate by liquid phase exfoliation method;

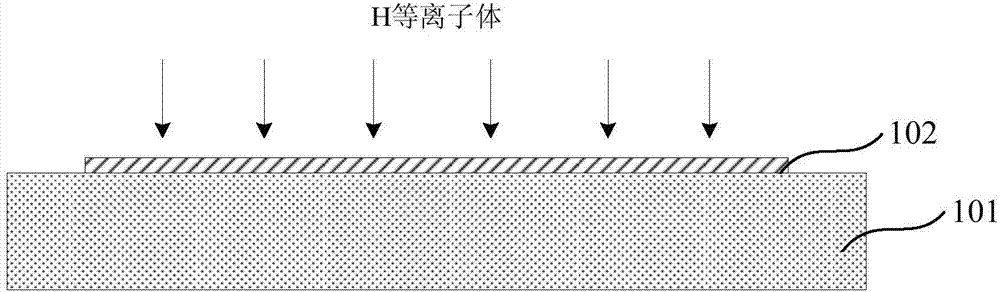

[0051] 2) placing the substrate in a reaction chamber, vacuumizing the reaction chamber, introducing a reducing gas and raising the temperature to a preset temperature, and then performing plasma pretreatment on the substrate;

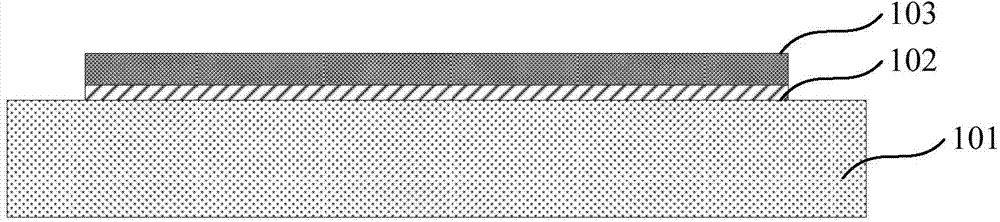

[0052] 3) Keep feeding the reducing gas and feeding the growth gas, and use plasma-enhanced chemical vapor deposition to grow vertical graphene on the surface of the horizontal graphene;

[0053] 4) Stop feeding the growth gas, cool down the reaction chamber, and then transfer the horizontal graphene and vertical graphene to the surface of the chip to be dissipated.

[0054] The preparation method of the graphene chip...

Embodiment 2

[0081] The difference between this embodiment and Embodiment 1 is that this embodiment prepares a layer of horizontal graphene 104 on the surface of the vertical graphene 103 prepared in Embodiment 1, such as Figure 10 As shown, the method for preparing the horizontal graphene layer 104 can be the same as the method for preparing the horizontal graphene 102 in the first embodiment. Specifically, the steps of the preparation method of the graphene-based chip heat dissipation material of the present embodiment are as follows:

[0082] 1) Provide a substrate 101, and prepare horizontal graphene 102 on the substrate 101 by liquid phase exfoliation method;

[0083] 2) placing the substrate 101 in a reaction chamber, vacuumizing the reaction chamber, introducing a reducing gas and raising the temperature to a preset temperature, and then performing plasma pretreatment on the substrate 101;

[0084] 3) Keep feeding the reducing gas and feeding the growth gas, and grow the vertical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com