Continuous pouring coil manufacturing method of cushion block without cake space

A technology for casting coils and manufacturing methods, applied in the field of transformer manufacturing, can solve the problems affecting the advancement of the overall structure, the material saving and energy saving effects are not obvious, and achieve the effect of improving the electrical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

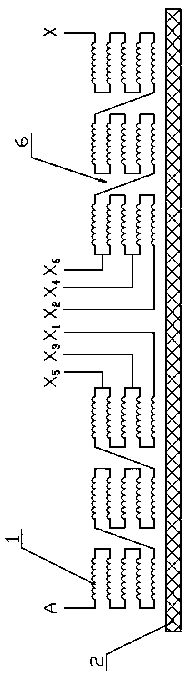

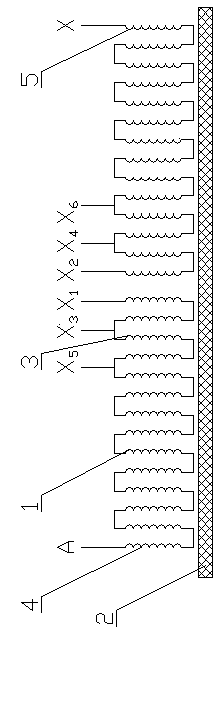

[0030] Example 1: 10KV, D connection method continuous casting coil without spacer between cakes

[0031] A high-voltage 10±2×2.5% KV, D-connection distribution transformer is designed to have a total of 455 turns (basic number of turns 411, tapping number of 11 turns×4), basic number of pie=411 / 9=45.667 (Odd integers have decimals), the decimal is an even integer, that is 46 pie, plus 8 pie, the total number of pie is 54 pie, full-turn pie is 9 turns, the maximum voltage between the pie is 415.8V, tap X1 —X3, X3—X5, X2—X4, X4—X6 are set in the middle to the end of the pie at a position that is 1 pie, and each tap is 11 turns of continuous casting coils without pads between pie blocks, starting from the first The cake is wound to the 24th cake, a total of 24 cakes, wound with a 2.5X12.5 double glass fiber wrap and a film winding wire, and the odd number cake is coiled according to the inverted position, and the even number cake is coiled according to the normal winding. The firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com