Pipeline leakage monitoring system and method

A technology of pipeline leakage and monitoring system, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as high cost, difficult to achieve, and inability to accurately measure pressure changes, and achieve fast response speed. , long service life, convenient long-distance transmission and processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

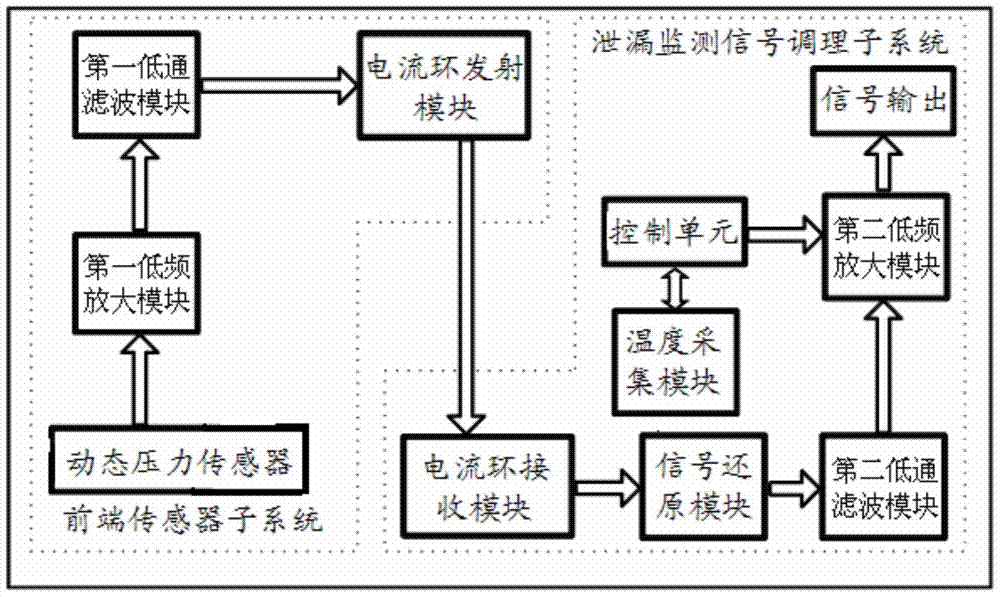

[0047] see figure 1 , a pipeline leakage monitoring system provided by an embodiment of the present invention includes a front-end sensor subsystem and a leakage monitoring signal conditioning subsystem; After performing amplification and filtering processing, it is transformed into a current signal, and then the current signal is sent to the detection signal conditioning subsystem; the leakage monitoring signal conditioning subsystem is used to convert the received current signal into a dynamic pressure signal, Then the dynamic pressure signal is amplified and filtered to collect data.

[0048] Wherein, the front-end sensor subsystem includes: a dynamic pressure sensor, a first low-frequency amplification module, a first low-pass filter module, and a current loop transmitter module. The dynamic pressure sensor is used to collect the dynamic pressure signal generated by the dynamic pressure change of the pipeline at the moment of leakage; the dynamic pressure sensor is a dyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com