Spinning apparatus of rotor spinning machine

A spinning machine and free-end technology, which is applied in the field of spinning mechanism of the free-end spinning machine, can solve the problems such as the temperature rise of the pulling nozzle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

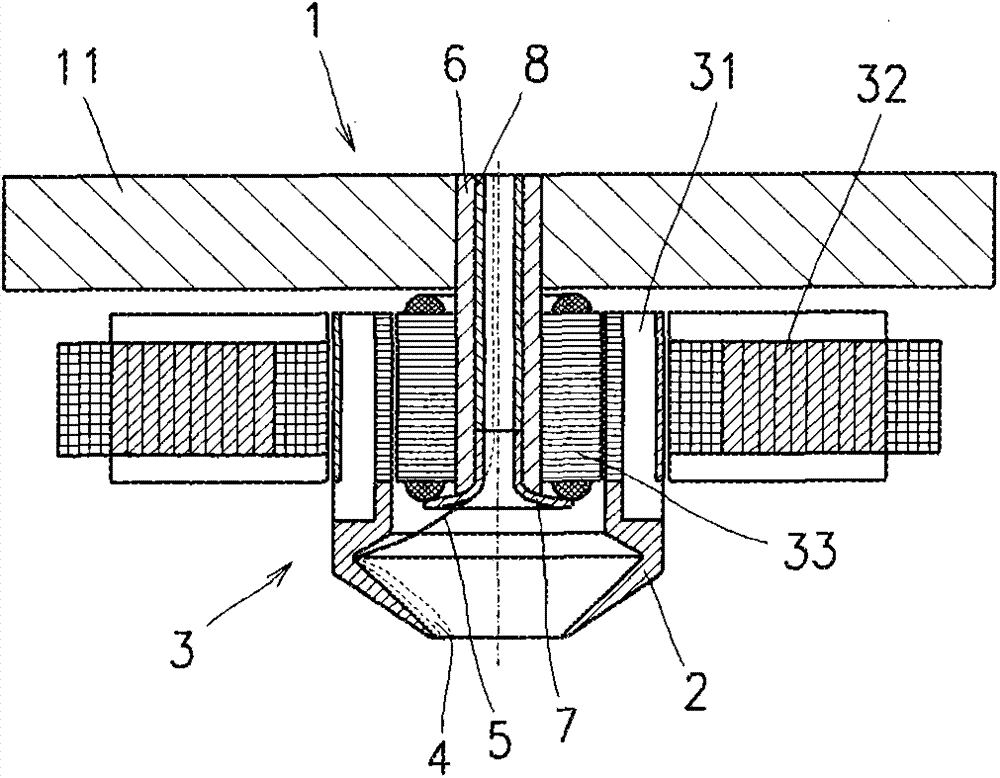

[0010] The open-end spinning machine comprises a plurality of spinning units 1 positioned adjacent to each other, each of them comprising a spinning rotor 2 coaxially mounted on radial and electromagnetic bearings and a drive system 3 on the electromagnetic function part 31 of the electric rotary drive. The radial electromagnetic bearing and the electromagnetic functional part 31 of the electric rotary drive of the drive system 3 are arranged between the stator 32 of the radial electromagnetic bearing and the stator 33 of the electric rotary drive, which is located in the spinning unit 1 In the cover 11, the cover 11 can be uncovered and installed on the main body of the spinning unit, in which the feeding device and picking device of the fiber sliver are arranged.

[0011] The spinning rotor 2 is formed by a body open on both sides, which is provided with an inlet hole for the entry of the picked fibers 4 and an outlet hole for the exit of the spun yarn 5, which continues to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com