Method and process for extracting 4-androstenedione from phytosterol aqueous phase fermentation liquor

A technology of androstenedione and phytosterol, applied in the field of fermentation, can solve problems such as troublesome separation and refining process, and achieve the effects of simplifying the extraction and refining process, reducing impurities and improving product quality

Active Publication Date: 2014-05-07

SHANDONG SITO BIO TECHNOLOGY CO LTD

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned solvents have no selectivity (or low selectivity) to the two substances of phytosterol and 4-androstenedione. As a result, after the extraction of the above-mentioned solvents, both substances are extracted into the organic solvent, It has brought a lot of trouble to the subsequent separation and refining process (the purpose of refining is to prepare high-purity 4-androstenedione)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0082]

[0083]

example 2

[0085]

[0086]

example 3

[0088]

[0089]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

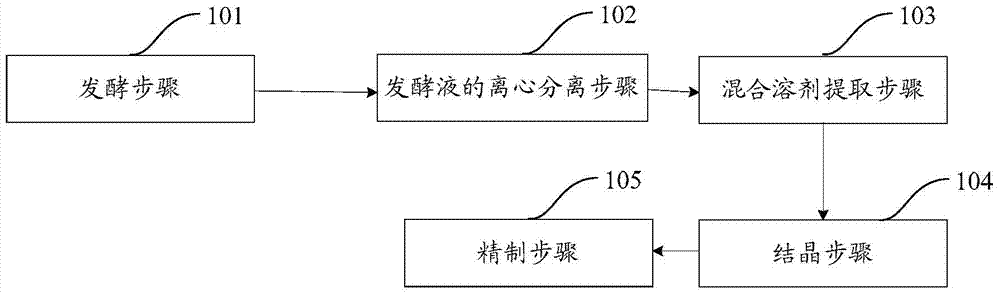

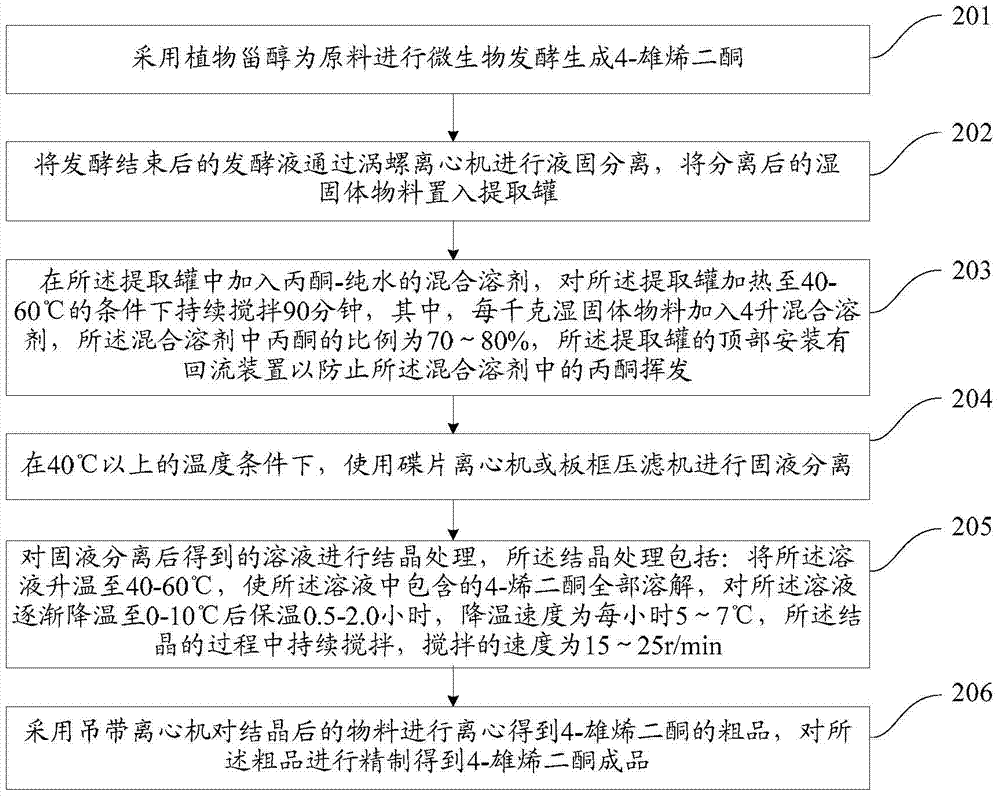

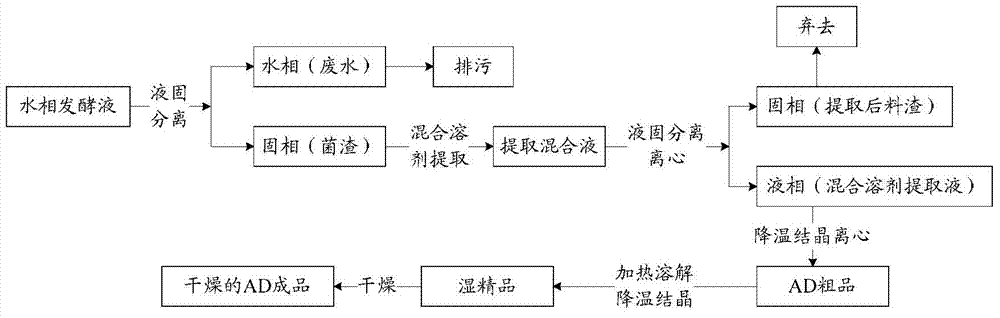

The invention provides a method and process for extracting 4-androstenedione from phytosterol aqueous phase fermentation liquor. The method comprises the following steps: performing microbial fermentation on phytosterol serving as a raw material to generate 4-androstenedione; performing liquid-solid separation on the fermentation liquor generated at the end of fermentation through a centrifugal machine, and extracting a wet solid material; adding a acetone-purified water mixed solvent into the wet solid material, continuously stirring for 60-90 minutes under the condition that the temperature is raised to 40-60 DEG C, and performing solid-liquid separation under the temperature condition of higher than 40 DEG C; crystallizing the solution obtained through solid-liquid separation; centrifuging the crystallized material to obtain a coarse product of the 4-androstenedione, and refining the coarse product to prepare the finished 4-androstenedione product. According to the method, the impurities in the 4-androstenedione product can be reduced, and the extracting and refining process is simplified.

Description

technical field [0001] The invention relates to the field of fermentation, in particular to a method and process for extracting 4-androstenedione from phytosterol aqueous phase fermentation liquid. Background technique [0002] 4-Androstenedione is an important intermediate in the synthesis of steroid hormone drugs. At present, it is mainly produced from phytosterols as the main raw material through microbial fermentation. Since it is difficult to convert all phytosterols into 4-androstenedione during the fermentation process, there are two substances of phytosterols and 4-androstenedione in the fermentation broth after the fermentation is finished. After the fermentation is finished, it is necessary to separate and extract 4-androstenedione from the fermentation broth with an appropriate organic solvent. [0003] At present, there are many kinds of organic solvents used in this extraction process in China, such as ethyl acetate, butyl acetate, acetone, methanol, ethanol, d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12P33/02C07J1/00

Inventor 何建勇刘艳玲潘之安

Owner SHANDONG SITO BIO TECHNOLOGY CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com