Preparation method of high-brittleness transparent rock material test piece

A rock material, brittle technology, applied in the field of preparation of highly brittle transparent rock material specimens with three-dimensional built-in fractures, can solve the problems that affect the experimental rules and the accuracy and authenticity of the results, the high degree of stress concentration in the front edge of the crack, and the degree of brittleness. Without high-level problems, the production process is simple and practical, the heat release is obvious, and the transparency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

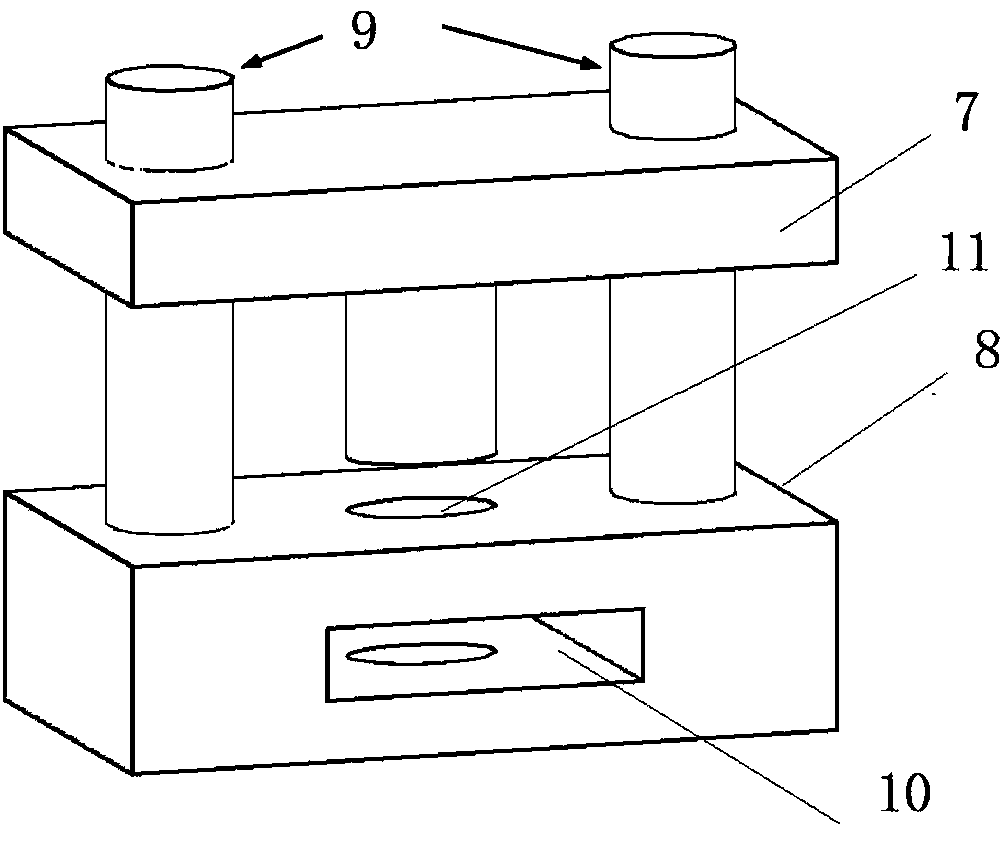

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] A method for preparing a highly brittle transparent rock-like material specimen. The raw materials include CY-39 type resin and YS-T31 type curing agent, the mass ratio of the two is 100:34 or the volume ratio is 100:41; the specific steps are:

[0034] (1) Material weighing

[0035] Measure 500ml of CY-39 resin material and 200ml of YS-T31 curing agent.

[0036] (2) Material mixing

[0037] Pour the resin and curing agent into the mixing drum according to the mixing ratio, and stir continuously with a glass rod to make it fully mixed to form a mixture. When stirring, pay attention to the materials at the bottom of the container and the side wall, so that the materials at this part are also fully mixed, and then Put it in a vacuum box for half an hour to remove air bubbles;

[0038] (3) Casting molding and maintenance

[0039] Place the mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com