Polydimethylsiloxane surface modification method based on hydrophobin/methylcellulose

A technology of polydimethylsiloxane and methylcellulose, which is applied in the field of surface modification of polydimethylsiloxane microfluidic chips, can solve problems such as unstable physical adsorption coatings, and achieve high efficiency The effects of reproducible separation, suppression of non-specific adsorption, and improvement of chromatographic peak shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

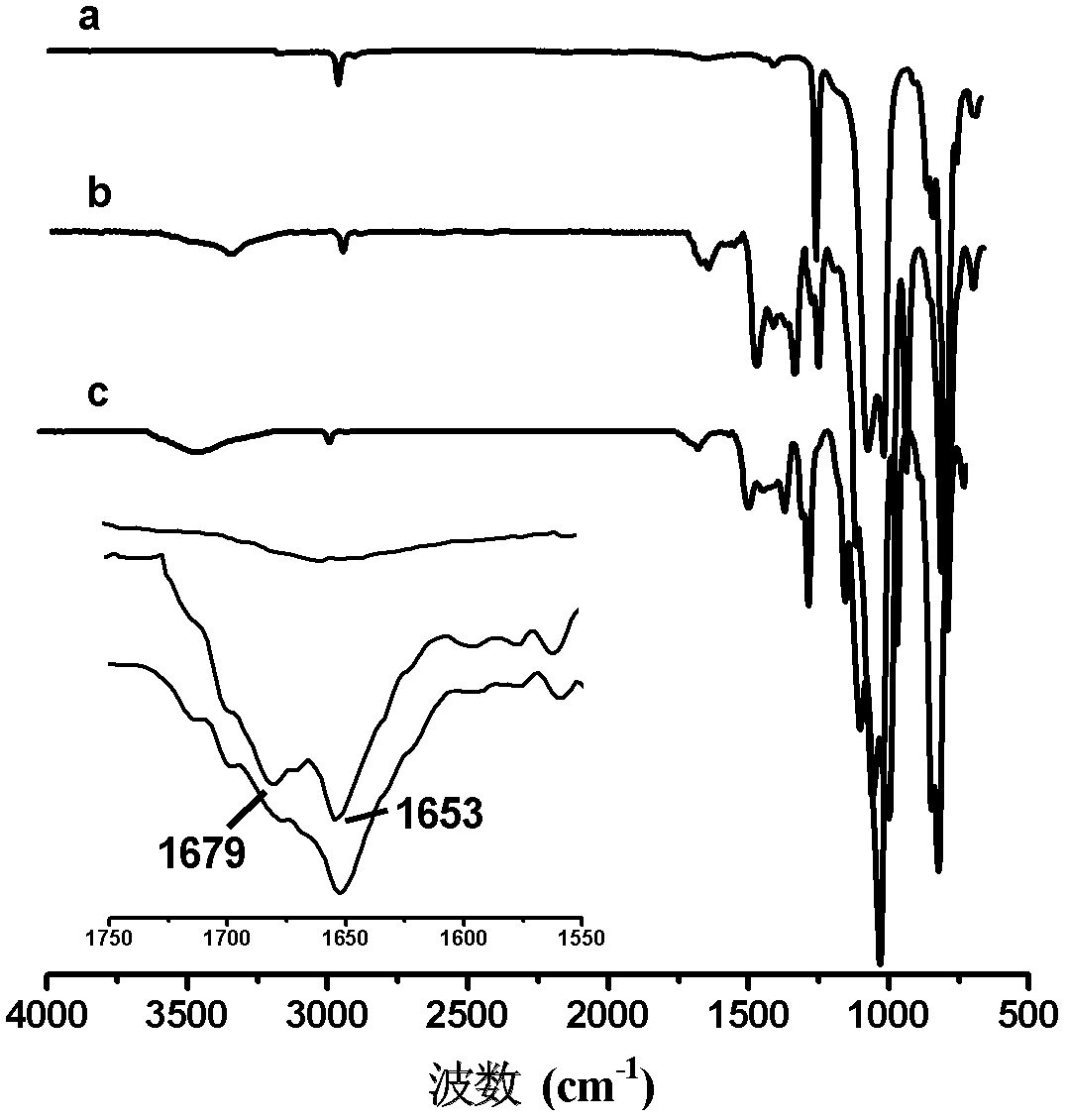

Method used

Image

Examples

Embodiment 1

[0021] Soak the microchannel of the polydimethylsiloxane chip with 1mol / L NaOH aqueous solution for 5 minutes for activation treatment, then wash it with deionized water until neutral, and then wash it with 20mmol / L PBS buffer solution with a pH value of 7.4 Rinse to obtain the polydimethylsiloxane microfluidic chip after NaOH activation treatment. Add hydrophobin SC3 and methylcellulose into 20mmol / L PBS buffer with a pH value of 7.4, add 1.0mg hydrophobin SC3 and 0.5g methylcellulose to each liter of PBS buffer, and prepare a surface modifier. Use a syringe to inject a surface modifier into the microchannel of the polydimethylsiloxane microfluidic chip after NaOH activation treatment, incubate at room temperature for 15 minutes, and heat at 65°C for 30 minutes to obtain surface-modified polydimethylsiloxane oxane.

Embodiment 2

[0026] In this example, the method for activating the polydimethylsiloxane microfluidic chip with NaOH is the same as that in Example 1. Add hydrophobin SC3 and methylcellulose to 10mmol / L borax buffer with a pH value of 9.5, add 1.0mg hydrophobin SC3 and 0.5g methylcellulose to each liter of borax buffer to prepare a surface modifier, Use a syringe to inject a surface modifier into the microchannel of the polydimethylsiloxane microfluidic chip after NaOH activation treatment, incubate at room temperature for 15 minutes, and heat at 65°C for 30 minutes to obtain surface-modified polydimethylsiloxane oxane.

Embodiment 3

[0028] In this example, the method for activating the polydimethylsiloxane microfluidic chip with NaOH is the same as that in Example 1. Add hydrophobin SC3 and methylcellulose to 50mmol / L Tris-HCl buffer with a pH value of 8.0, add 0.5mg hydrophobin SC3 and 0.5g methylcellulose to each liter of borax buffer, and prepare surface modification agent, use a syringe to inject the surface modifier into the microchannel of the polydimethylsiloxane microfluidic chip after NaOH activation treatment, incubate at room temperature for 20 minutes, and heat at 60°C for 30 minutes to obtain surface-modified polydimethylsiloxane base siloxane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com