A kind of synthetic method of polyester resin

A synthesis method and technology of polyester resin, applied in the field of organic polymer material synthesis, can solve the problems of unstable temperature rise rate control, poor stability between batches, and unfavorable separation of alcohol and water, and achieve the target and stable performance, The effect of using performance improvement and unit consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

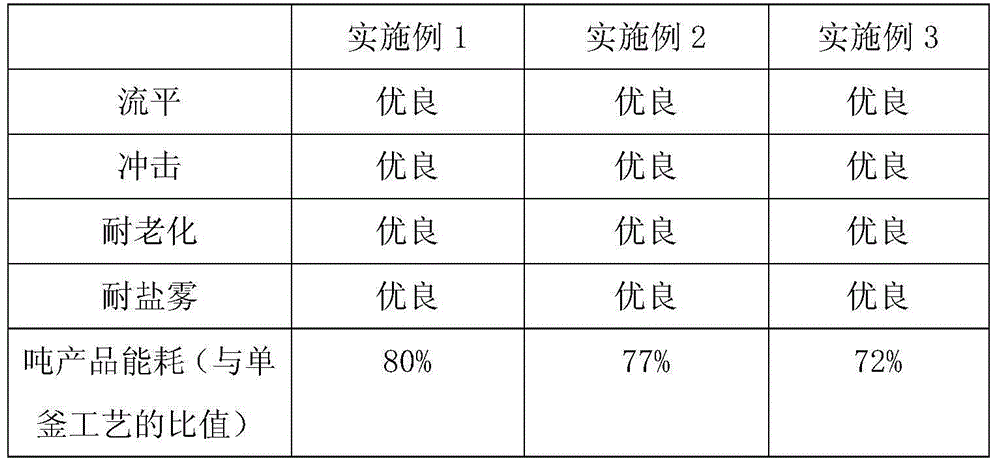

Examples

Embodiment 1

[0011] A method for synthesizing polyester resin. The steps include esterification reaction and polycondensation reaction. The esterification reaction is carried out in a primary reaction kettle, and the polycondensation reaction is carried out in a secondary reaction kettle.

[0012] The esterification reaction step is divided into a dehydration polymerization reaction and an end-capping reaction. The dehydration polymerization reaction step is: put the dibasic alcohol and the dibasic acid into the first-stage reactor, and the reaction parameters are: the reaction temperature is 230°C, and the temperature gradient is 200°C. The heating rate is 4°C / min, the heating rate is 1.5°C / 15min at 200-230°C, and the pressure is 0.25MP. Make the pressure reach the set value before reaching the reaction temperature; The target acid value is 9, and the reaction parameters are controlled by a decentralized control system (DCS); the mass ratio of dibasic alcohol and dibasic acid is 1.2:1, the...

Embodiment 2

[0016] A method for synthesizing polyester resin. The steps include esterification reaction and polycondensation reaction. The esterification reaction is carried out in a primary reaction kettle, and the polycondensation reaction is carried out in a secondary reaction kettle.

[0017] The esterification reaction step is divided into dehydration polymerization reaction and end-capping reaction. The dehydration polymerization reaction step is: put dibasic alcohol and dibasic acid into a first-stage reaction kettle, and the reaction parameters are: reaction temperature 220°C, temperature gradient before 200°C The temperature rise rate is 6°C / min, the temperature rise rate is 1.5°C / 15min at 200-220°C, and the pressure is 0.25MP. When the reaction temperature is reached, the pressure reaches the set value at the same time; the reaction is completed to reach the target acid value of the polyester resin, so The target acid value is 12, and the reaction parameters are controlled by a d...

Embodiment 3

[0021] A method for synthesizing polyester resin. The steps include esterification reaction and polycondensation reaction. The esterification reaction is carried out in a primary reaction kettle, and the polycondensation reaction is carried out in a secondary reaction kettle.

[0022] The esterification reaction step is divided into dehydration polymerization reaction and end-capping reaction. The dehydration polymerization reaction step is: put dibasic alcohol and dibasic acid into a first-stage reaction kettle, and the reaction parameters are: reaction temperature 225°C, temperature gradient before 200°C The heating rate is 5°C / min, the heating rate is 1.5°C / 15min at 200-225°C, and the pressure is 0.25MP. Make the pressure reach the set value before reaching the reaction temperature; the reaction is completed when the target acid value of the polyester resin is reached, so The target acid value is 6, and the reaction parameters are controlled by a distributed control system (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com