Cationic polymer

A technology of cationic polymer and cationic degree, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of slow dissolution rate and difficult use, and achieve the effects of low water content, less scum generation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

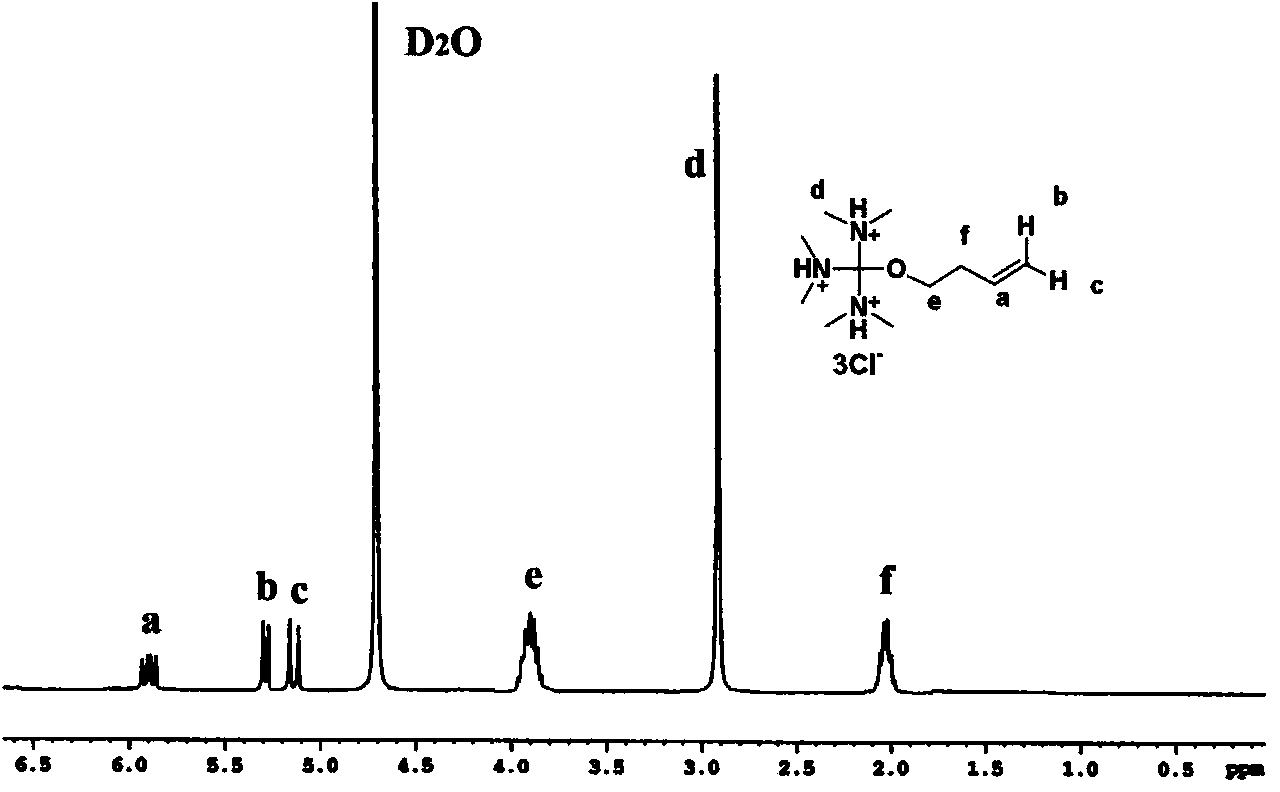

[0059] The preparation of embodiment 1, cationic polymer MCF-1

[0060] The reaction equation is as follows:

[0061]

[0062] 22g acrylamide (Sinopharm Chemical Reagent Co., Ltd.) (C 3 h 5 NO, 71.08g / mol) and 18g of tris(dimethylamino)methyl-3-butenyl ether hydrochloride monomer were dissolved in 50mL deionized water to obtain monomer aqueous solution, and then the monomer aqueous solution was added to 8.25g Span-80 (Haian Petrochemical Plant, Jiangsu Province) and 6.75 g Tween-80 (Haian Petrochemical Plant, Jiangsu Province) in 135 g cyclohexane (Sinopharm Chemical Reagent Co., Ltd.), emulsified under a high-shear homogeneous emulsifier After 15 minutes, the emulsion was obtained. Add the above-mentioned emulsion into a 500mL four-neck bottle equipped with a stirrer, a thermometer, a dropping funnel, and a ventilation tube, and after stirring for 20 minutes, add 0.06g of potassium persulfate (Sinopharm Chemical Reagent Co., Ltd.) and 0.02g of sodium bisulfite (Sinopha...

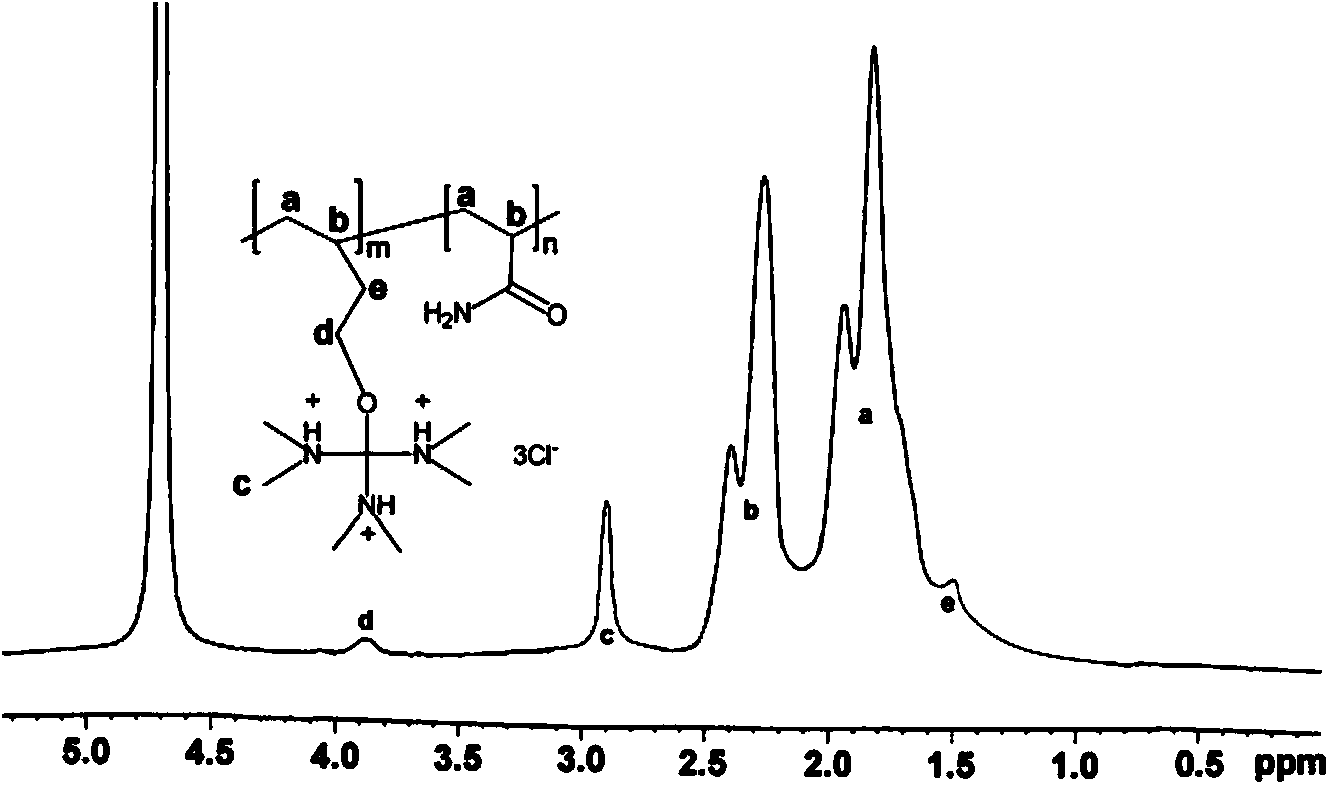

Embodiment 2

[0067] The preparation of embodiment 2, cationic polymer MCF-2

[0068] 16g of acrylamide and 24g of tris(dimethylamino)methyl-3-butenyl ether hydrochloride monomer were dissolved in 50mL of deionized water to obtain a monomer aqueous solution, and then the monomer aqueous solution was added to 8.25g of Span-80 In 135g cyclohexane with 6.75gTween-80, emulsify for 10min under a high-shear homogeneous emulsifier to obtain an emulsion. Add the above-mentioned emulsion into a 500mL four-necked bottle equipped with a stirrer, a thermometer, a dropping funnel, and a ventilation tube, and after stirring for 20 minutes with nitrogen and deoxygenation, add dropwise an aqueous solution containing 0.06g of potassium persulfate and 0.02g of sodium bisulfite 10 mL, control the reaction temperature to 45°C, and stop the reaction after 4 hours of constant temperature. Add acetone to precipitate, filter under reduced pressure, wash with acetone twice, and filter to obtain a powder or granula...

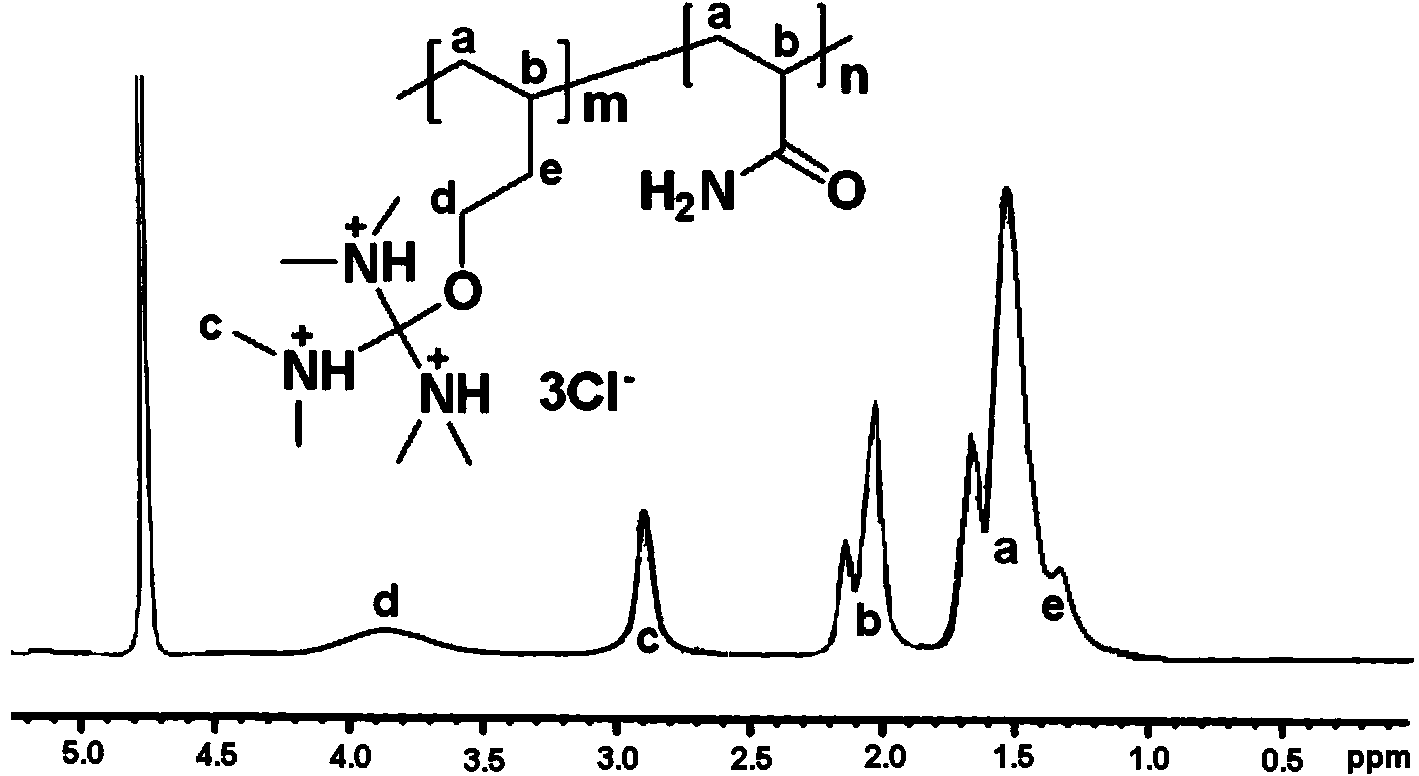

Embodiment 3

[0073] The preparation of embodiment 3, cationic polymer MCF-3

[0074] 11g of acrylamide and 29g of tris(dimethylamino)methyl-3-butenyl ether hydrochloride monomer were dissolved in 50mL of deionized water to obtain a monomer aqueous solution, and then the monomer aqueous solution was added to 8.25g of Span-80 In 135g cyclohexane of 6.75gTween-80, emulsify for 15min under a high-shear homogeneous emulsifier to obtain an emulsion. Add the above-mentioned emulsion into a 500mL four-necked bottle equipped with a stirrer, a thermometer, a dropping funnel, and a ventilation tube, and after stirring for 20 minutes with nitrogen and deoxygenation, add dropwise an aqueous solution containing 0.06g of potassium persulfate and 0.02g of sodium bisulfite 10 mL, control the reaction temperature to 45°C, and stop the reaction after 4 hours of constant temperature. Add acetone to precipitate, filter under reduced pressure, wash with acetone twice, and filter to obtain a powder or granular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com