Crystallization method for separating paraxylene

A technology of p-xylene and mixed xylene, which is applied in crystallization purification/separation, organic chemistry, etc., and can solve problems such as high energy consumption and fouling of pre-coolers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

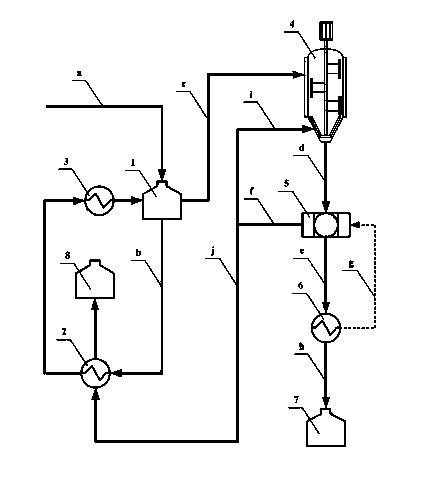

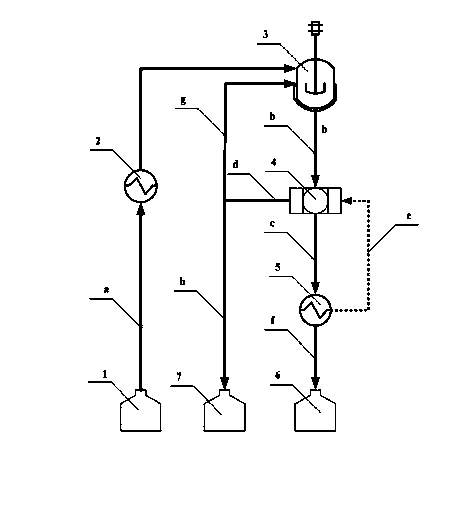

[0019] Such as figure 1 Said, the mixed xylene raw material a enters the raw material tundish 1, the temperature is 30°C, the flow rate is 1075kg / h, the p-xylene content is 80wt%, and a part of the mixed xylene raw material b passes through the mother liquor heat exchanger 2 and the precooler 3 Return to the raw material tundish 1 after cooling, the flow rate is 5375 kg / h, a part of the mixed xylene raw material c enters the crystallizer 4 for crystallization, the flow rate is 1075 kg / h, the temperature is 15°C, and the crystallization temperature is -17°C. The crystal slurry d in the crystallizer 4 is separated by the solid-liquid separator 5 to obtain p-xylene crystals e and crystallization and filtration mother liquor f. P-xylene crystal e is melted in melting tank 6, and melting temperature is 20 ℃, and the p-xylene of 20% by weight is used as washing liquid g to wash the crystal in solid-liquid separator 5, and the p-xylene of 80% by weight is used as product h enters pr...

Embodiment 2

[0022] According to the operating condition of embodiment 1, adopt as figure 1 In the crystallization method for separating p-xylene, the flow rate of mixed xylene raw material b is 10750 kg / h. The specific results are shown in Table 1.

[0023]

Embodiment 3

[0025] According to the operating condition of embodiment 1, adopt as figure 1 In the crystallization method for separating p-xylene, the flow rate of mixed xylene raw material b is 16125kg / h. The specific results are shown in Table 1.

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com