A Refractive Flow Mesh Flocculation Reactor

A grid flocculation and reaction device technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of increasing the investment cost and operating cost of the project, shorten the residence time, improve the efficiency and effect, and achieve the effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

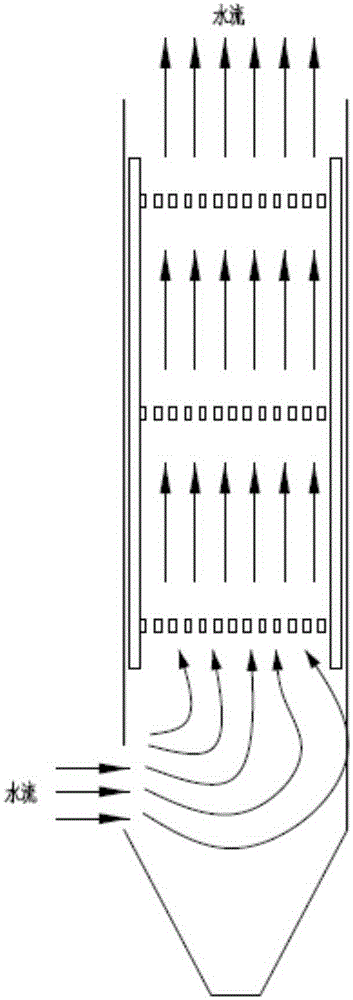

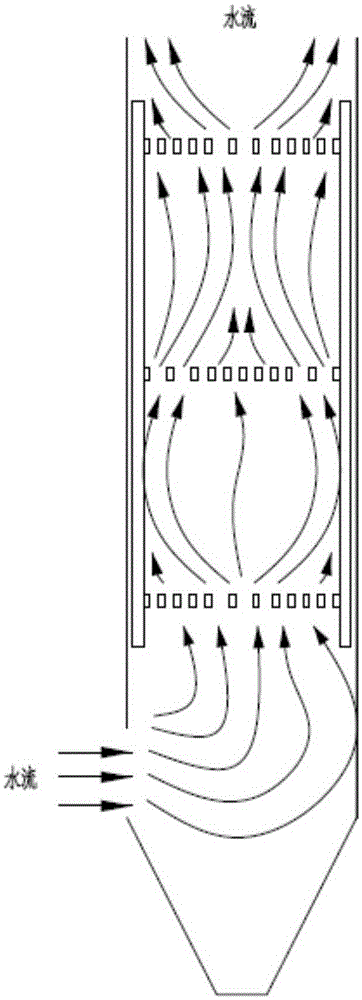

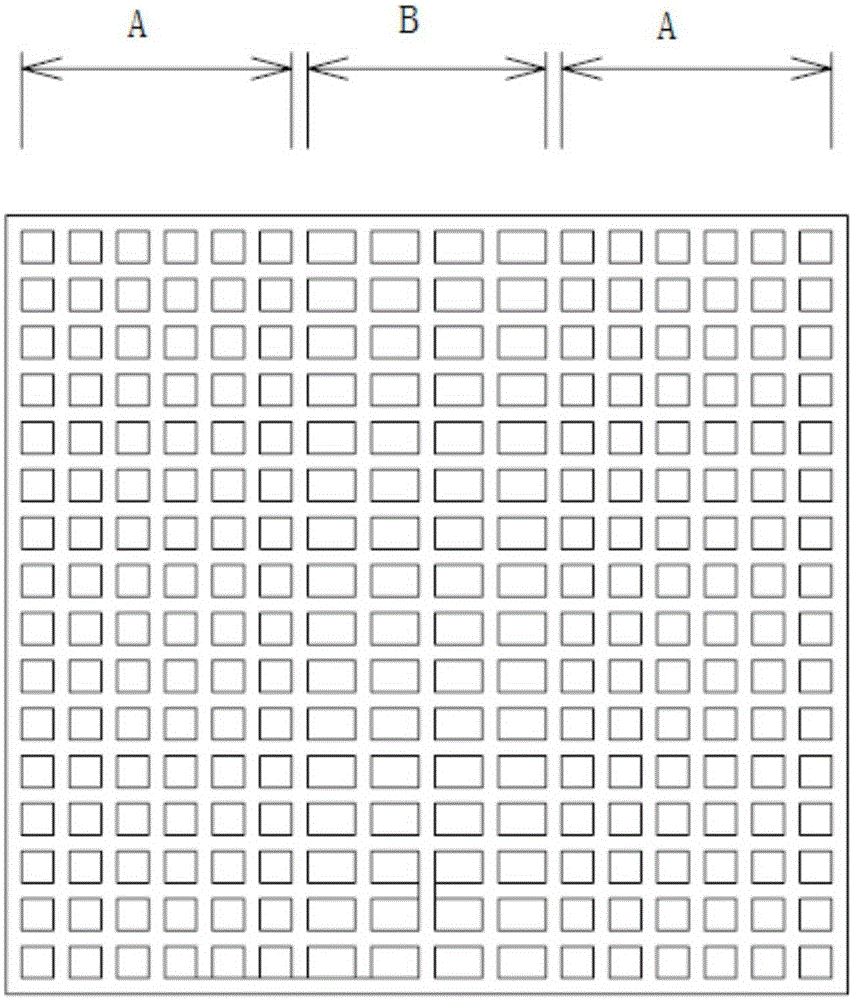

[0024] Such as Figure 3-5 As shown, the present invention is composed of an adjustable composite frame, a multi-layer bending flow grid and the like. The adjustable combined frame (1) is used as the skeleton of the reaction device, and the grid plates with different apertures A and B are used for reasonable layout. The grid plates are made of ethylene-propylene copolymer, the frame is made of stainless steel, and the grid plates are fixed by use. Beads and bolts are installed at different positions on the frame.

[0025] The adjustable combination frame (1) is designed with multiple positions for grid panels to be fixed, which can realize various spacing combinations of grid panels, that is, the spacing between grids is adjustable.

[0026] It is believed that layer grid a and grid b are made with different types of aperture specifications, and grid b(a) and grid b(a) skipping one layer can use the same type of aperture specifications, or they can use different types of aper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com