A production device for high-purity electronic-grade phosphoric acid

An electronic-grade phosphoric acid and production device technology, applied in phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of cumbersome production process, large floor space, low product yield, etc., to improve heat exchange rate, equipment Small footprint and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

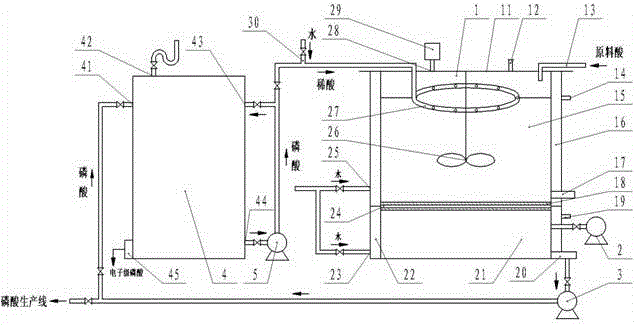

[0028] A production device for high-purity electronic-grade phosphoric acid, comprising a stirred crystallizer 1, a vacuum pump 2, an acid outlet pump 3, an acid adjustment tank 4, and a circulation pump 5; the stirred crystallizer 1, the acid outlet pump 3, and the acid adjustment tank 4 and the circulating pump 5 are connected in sequence through pipelines; the vacuum pump 2 is connected with the top of the lower section of the stirred crystallizer 1 through pipelines.

[0029] The stirred crystallizer 1 comprises a cover plate 11, a crystallization chamber 15, an agitator 26, a crystal washing device 27 and a suction filtration chamber 21; Room 21. The upper part and the lower part are separated by two layers of filter plates 18, filter holes are arranged on the filter plates 18, and filter cloth 24 is arranged between the two layers of filter plates 18. The outside of the crystallization chamber 15 and the suction filtration chamber 21 are provided with independent jacket...

Embodiment 2

[0035] A production device for high-purity electronic-grade phosphoric acid, comprising a stirred crystallizer 1, a vacuum pump 2, an acid outlet pump 3, an acid adjustment tank 4, and a circulation pump 5; the stirred crystallizer 1, the acid outlet pump 3, and the acid adjustment tank 4 and the circulating pump 5 are connected in sequence through pipelines; the vacuum pump 2 is connected with the top of the lower section of the stirred crystallizer 1 through pipelines.

[0036] The stirred crystallizer 1 comprises a cover plate 11, a crystallization chamber 15, an agitator 26, a crystal washing device 27 and a suction filtration chamber 21; Room 21. The upper part and the lower part are separated by two layers of filter plates 18, filter holes are arranged on the filter plates 18, and filter cloth 24 is arranged between the two layers of filter plates 18. The outside of the crystallization chamber 15 and the suction filtration chamber 21 are provided with independent jacket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com