Vein pump assembly for air maintenance tire

A technology of air maintenance and air pump, which is applied in tire parts, tire measurement, tire edges, etc., and can solve the problems of vehicle braking and handling performance degradation, fuel economy and tire life degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

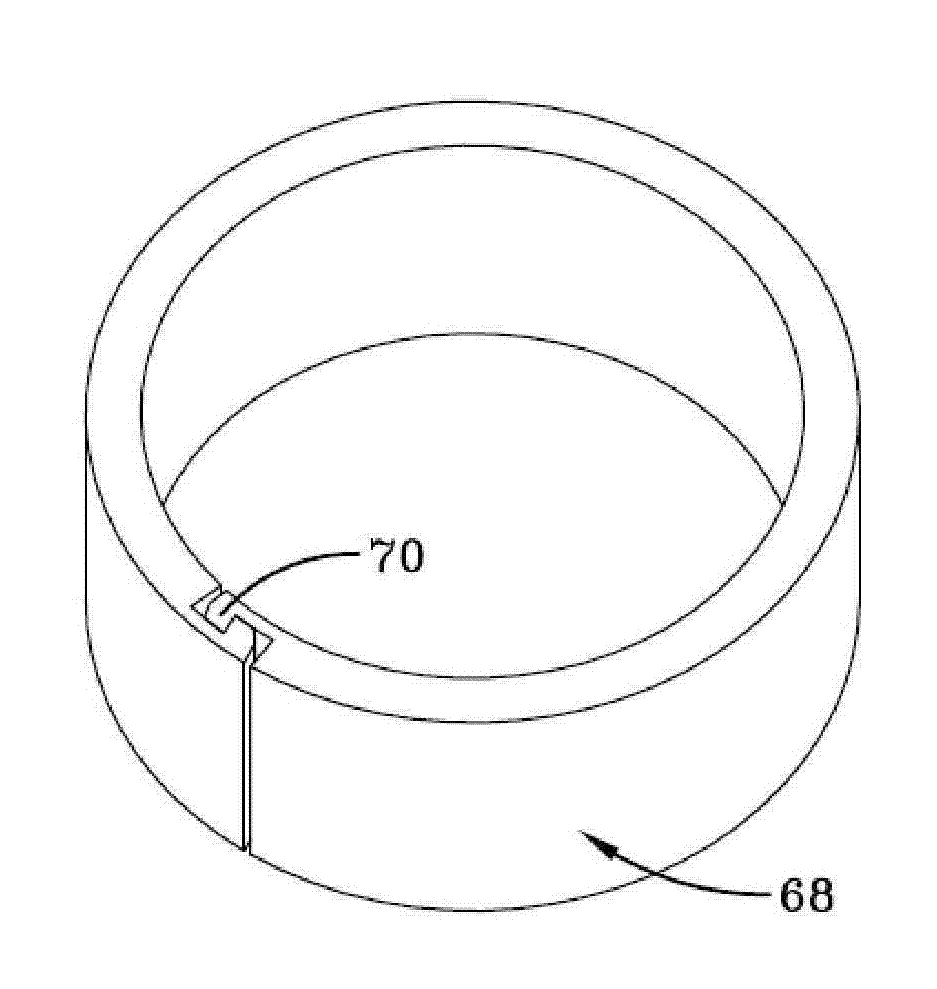

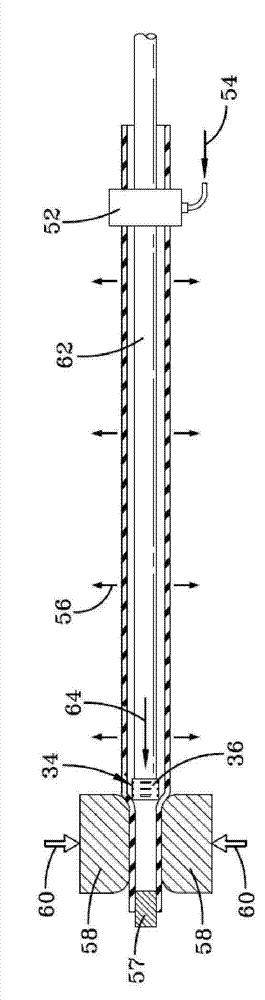

[0078] refer to figure 1 , tire and air maintenance pump assembly 10 (forming an air maintenance tire or “AMT”) includes a tire and vascular pump assembly 28 . US Patent Nos. 8,113,254 and 8,042,586 describe the general operation of peristaltic pumps used in tires, both filed on December 12, 2009 and filed on February 14, 2012 and October 25, 2011, respectively. Issued on , and is incorporated herein by reference in its entirety. The tire is constructed to provide a tread region 14 , a pair of sidewalls 16 , 18 extending from opposing bead regions 22 , 24 to the tire tread region 14 . The tire encloses the tire cavity 20 . The air maintenance assembly includes an elongated air tube 26 enclosing an annular passage 28 . Tube 42 is formed from a resilient, elastomeric, flexible material, such as plastic or rubber compounds and compositions, which is capable of withstanding repeated deformation cycles in which the tube is deformed into a flat state by an external force and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com