A processing method for open case without stop plate

A technology for opening casings and processing methods, which is applied in the field of mechanical parts processing, and can solve problems such as the inability to meet the finishing requirements of the outer surface, the increased machining allowance of the outer surface of the casing, and the uneven appearance allowance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

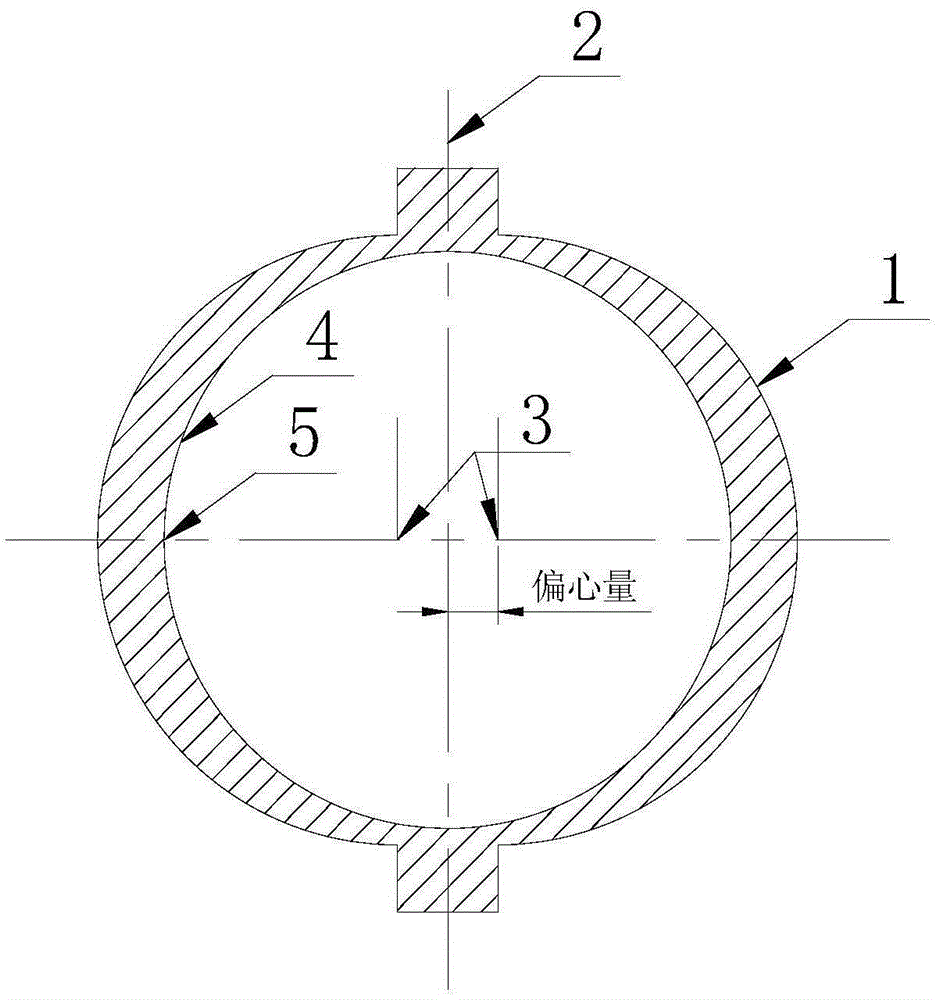

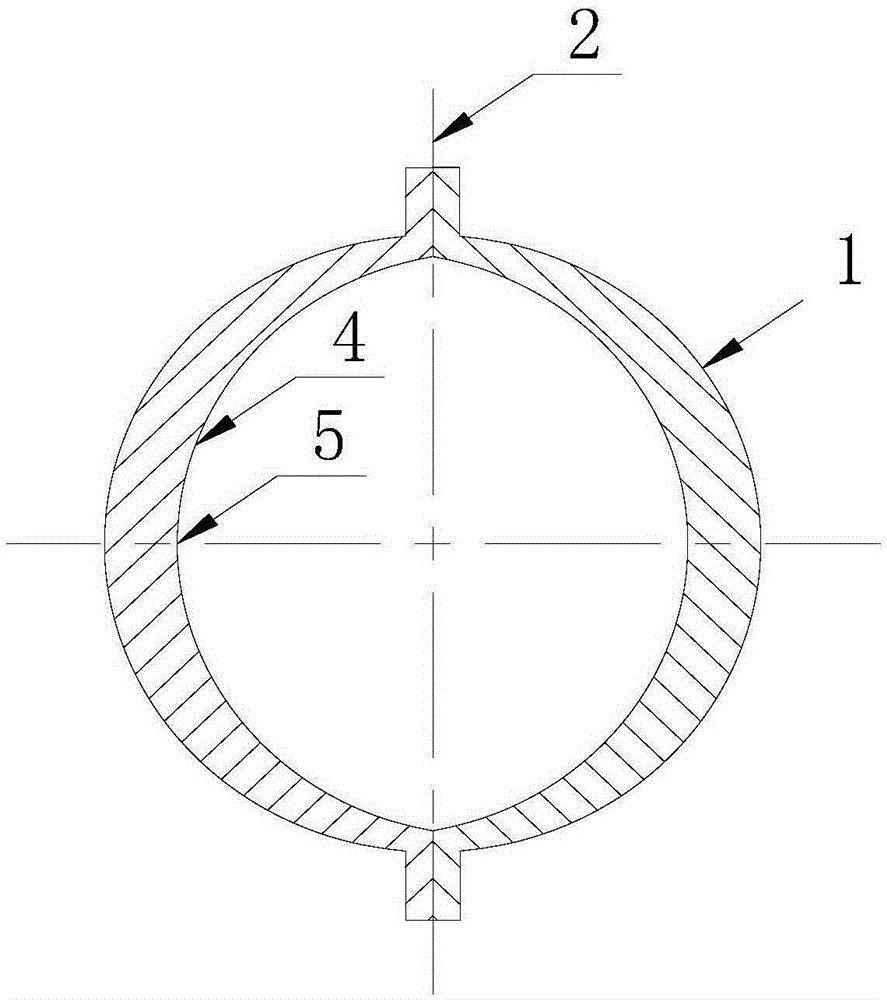

[0029] refer to figure 1 and figure 2 , the processing method of the whole forging without the stop plate to the open case, the specific processing steps are as follows:

[0030] Step 1. Determine the outer eccentricity of the casing

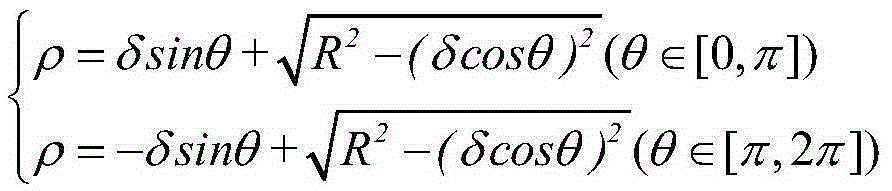

[0031] The outer contour section of the casing is two semicircles, the centers 3 of which are on the same line but not at the same point, and the two centers 3 deviate from the center of rotation of the casing by a certain distance, and this distance is the eccentricity δ, such as figure 1 shown. The amount of eccentricity is equal to the unilateral margin z of the finish machining of the joint surface of the casing 1 , between 1.50 and 2.00mm. The eccentricity δ is given as 1.75mm according to the unilateral margin of the joint surface of the casing.

[0032] Step 2. Determine the finishing allowance of the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com