A welding method for anti-moisture and anti-vibration LED lamps

A technology of LED lamps and welding methods, applied in welding equipment, manufacturing tools, printed circuits, etc., can solve the problem of short, shortest or even no more than 30 days, solar LED lamps cannot work normally, and aggravate aluminum-based circuits in solar LED lamps. Problems such as board detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A welding method for moisture-proof and anti-vibration LED lamps. The welding equipment and components include welding machines, aluminum-based circuit boards, LED lamps, cleaning agents, solder paste and circuit testing equipment. The welding method for moisture-proof and anti-vibration LED lamps The specific steps are as follows:

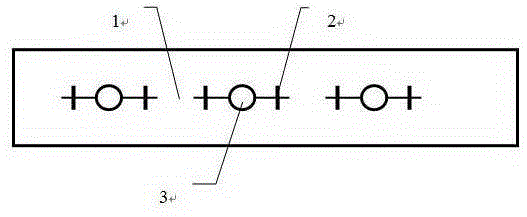

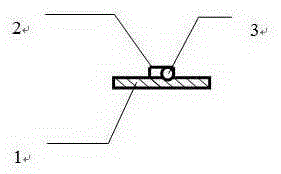

[0025] (1) Pre-installed metal crimping line 2: on the aluminum-based circuit board 1, the two ends of the metal crimping line 2 are pre-welded on the positive end or the negative end to be welded to ensure that the metal crimping line and the aluminum-based circuit The space between the positive or negative terminal to be soldered on the board allows the LED lamp to be inserted into the positive or negative terminal to be soldered;

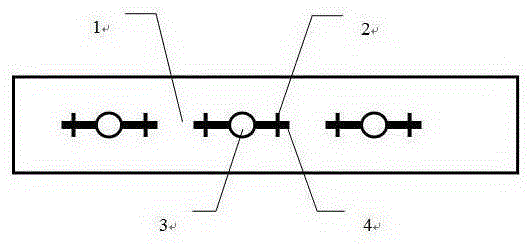

[0026] (2) Cleaning: Use a cleaning agent to clean the positive and negative terminals on the aluminum-based circuit board 1 that need to be welded by the soldering point 4;

[0027] (3) Cleaning: Clean the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com