Automatic production equipment for polycarboxylate superplasticizer

A technology for production equipment and water reducing agent, applied in the field of polycarboxylate water reducing agent production equipment, can solve the problems of polycarboxylate water reducing agent without a complete process control system, low labor productivity, etc., and achieve good product quality homogeneity , The degree of automation is improved, and the effect of precise process formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

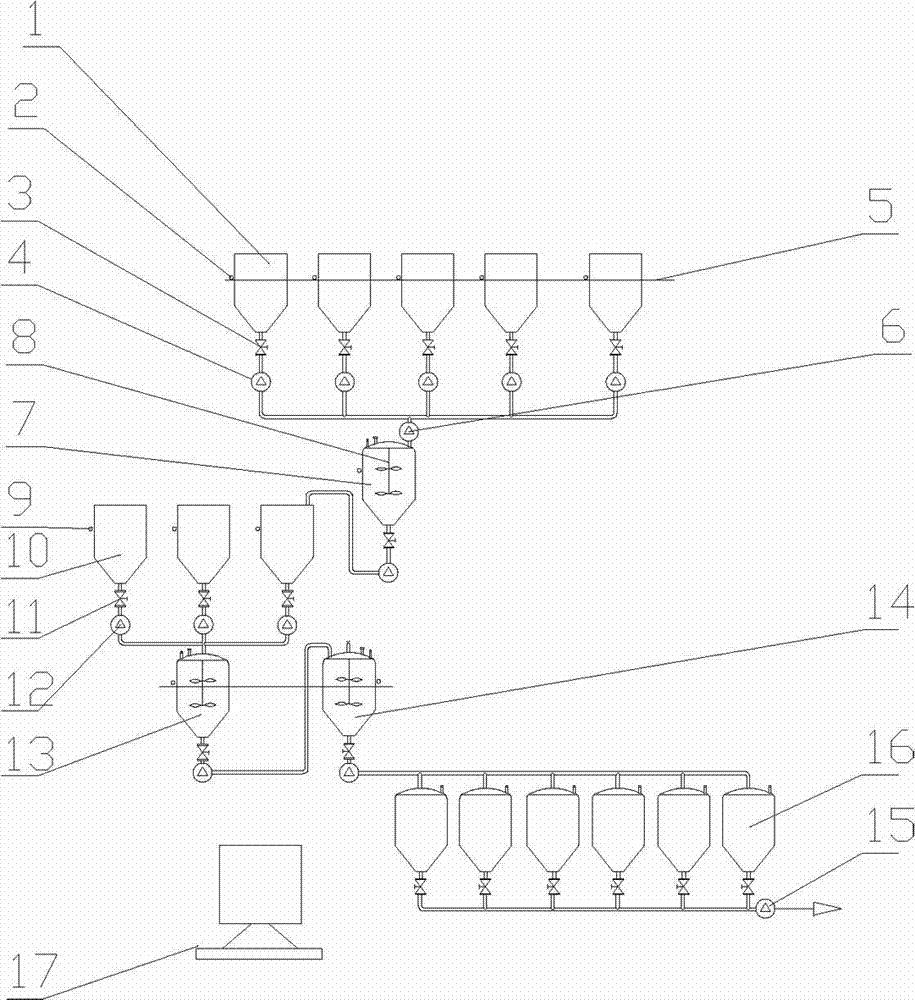

[0017] Polycarboxylate superplasticizer production automation production equipment, including liquid raw material adding device, reaction kettle, powder raw material adding device, comprehensive stirring device, finished product canning device and computer control system, it is characterized in that the liquid raw material adding device It includes multiple sets of liquid raw material tanks 1, liquid material dripping metering pump 6 and metering platform 5. Liquid raw material tank 1 is equipped with liquid material level module 2, and the outlet of liquid raw material tank 1 is equipped with pneumatic butterfly valve 3 and frequency conversion control pump 4. The multiple groups of liquid raw material tanks 1 and the liquid material dripping metering pump 6 are connected in parallel through pipelines;

[0018] The reactor 7 is provided with a stirring device 8 and an electric heating device, the reactor 7 shell is provided with pressure, temperature, and time controllers, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com