Welding rack for circuit board welding

A welding frame and circuit board technology, applied in the field of welding frame, can solve the problems of inconvenient welding and poor welding effect, and achieve the effects of good usability, large welding space and good light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

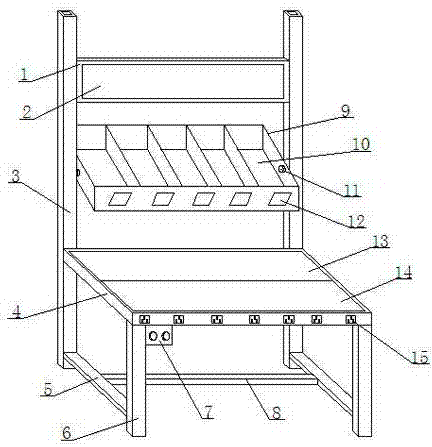

[0015] Such as figure 1 The shown welding frame for circuit board welding includes a square welding platform 4, the lower ends of the four corners of the welding platform 4 are connected with pillars 6, and the pillars 6 of the two corners of the rear end of the welding platform 4 are all upward Brackets 3 are formed by extension, and a storage box 9 and a drawing splint 1 are sequentially arranged between the brackets 3; an LED light source board 13 is arranged on the welding table 4, and a transparent plate is arranged on the upper end of the LED light source board 13, and a transparent board is arranged on the transparent board. Also be provided with an insulating transparent working board 14, the front end of the welding station 4 is also provided with a plurality of power jacks 15; There are a plurality of storage slots 10; the drawing splint 1 is provided with an LED light board 2 inside and the drawing splint 1 is a transparent glass plate.

[0016] The welding station...

Embodiment 2

[0018] In this embodiment, the following structure is added on the basis of Embodiment 1: a switch box 7 is provided at the front end of the welding station 4 .

[0019] In this embodiment, in order to facilitate switching of the LED light source board 13, the LED lamp board 2 and the power jack 15, a switch box 7 is also provided at the front end of the welding station 4, and the switch box 7 can control the circuit switch of the above structure, which is convenient for the staff to use.

Embodiment 3

[0021] This embodiment adds the following structure on the basis of embodiment 1 or embodiment 2: the front end of the storage box 9 is provided with a plurality of identification grooves 12 corresponding to the storage slots 10 .

[0022] In this embodiment, in order to make it easier for the staff to pick and place the corresponding electrical devices, each storage slot 10 is provided with an identification slot 12, and identification pieces for recording information such as the name, model, and service conditions of the electrical device can be pasted in the identification slot 12. Workers will not be confused when picking up the discharge device, avoiding welding errors caused by welders taking wrong electrical parts, and improving welding reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com