Method for preparing high-color-rendering-index white light device through electric annealing or thermal annealing

A white light device and thermal annealing technology, which is applied in the direction of electric solid state devices, electrical components, semiconductor devices, etc., can solve the problem of the difficulty in preparing white light devices with high color rendering index, insufficient industrial application, and unrealized industrialization of solid-state white light lighting devices and other problems, to achieve the effect of simple process and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further elaborated.

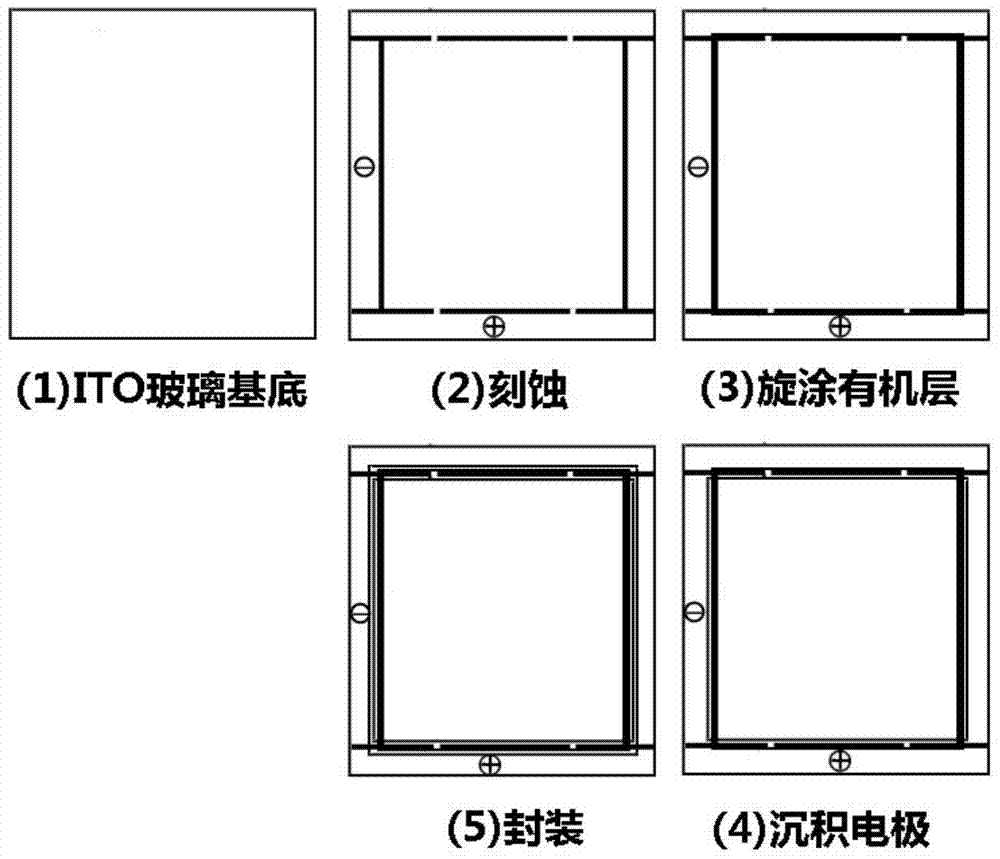

[0028] The implementation of this solution includes the selection of conductive base material, electrode patterning, preparation of electron injection layer, preparation of light emitting layer, electrical or thermal annealing treatment, electrode deposition, product packaging and so on. Such as figure 1 As shown, the main steps include (1) ITO glass substrate; (2) etching; (3) spin-coating organic layer; (4) electrode deposition; (5) encapsulation.

[0029] Choice of electrical base material: The electrode base material can be indium tin oxide (Indium tin oxide, ITO for short) conductive glass, or other flexible transparent base materials with ITO, such as PET plastic, PC, PMMA, PAN, etc. The choice of substrate material mainly depends on the purpose of the target lighting product. For example, flat white light source, it is more suitable to choose ITO conductive glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com