Processing cartridge and image forming equipment comprising same

A technology for processing boxes and powder bins, which is applied in the fields of electric recording process equipment using charge patterns, electric recording technology using charge patterns, and electric recording techniques, and can solve complex structure of processing boxes, numerous installation procedures, production efficiency and cost Advanced problems, to achieve the effect of improving image forming quality, improving developing quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

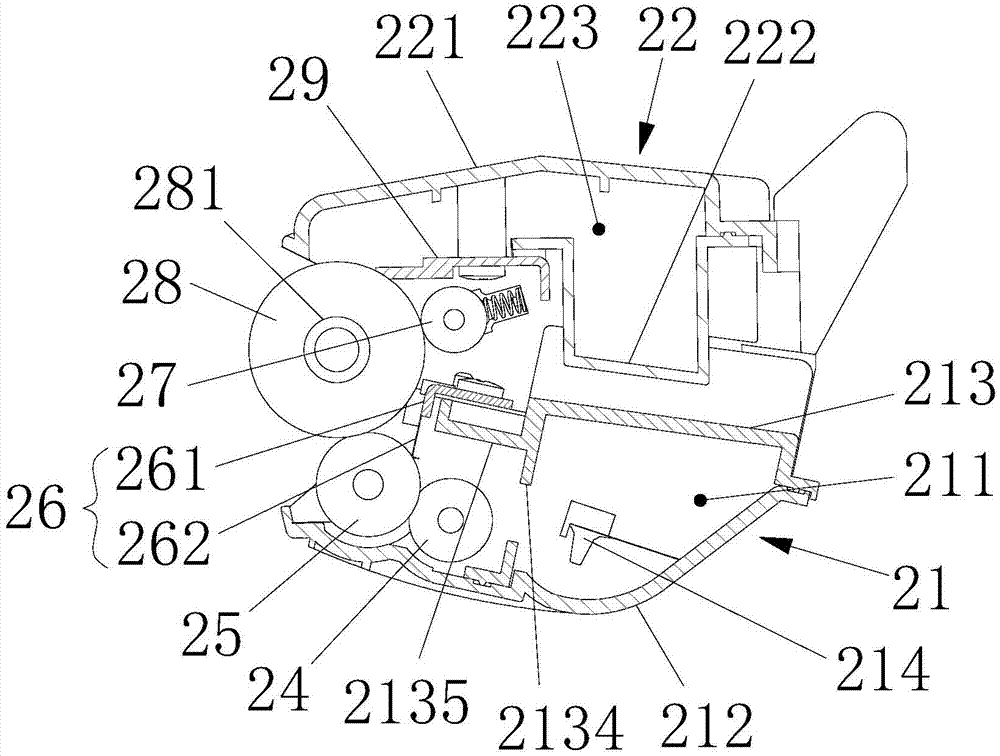

[0064] Further, as attached Figure 7c As shown, the present invention provides a third embodiment, in which only one protrusion is set in the shaft limiting hole 231, and after the rotating shaft 281 is inserted into the rotating shaft limiting hole 231, there is still more space, so that the rotating shaft 281 can be placed in the rotating shaft limiting hole 231. Move in the space until the rotating shaft 281 touches the protrusion and stops moving, and the photosensitive drum 28 also stops rotating thereupon. Based on the above principles, the shaft end of the rotating shaft 281 can be set in various shapes without limitation. For example, it can be set in a straight line, or half the size of a straight line, or D-shaped, triangular, etc., as long as it can It only needs to be in contact with the above-mentioned protrusions and be blocked by the protrusions. This embodiment provides more installation space for the rotating shaft 281 , and the shaft end is not easy to inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com