AOD furnace smoke and dust high and medium temperature waste heat positive energy recovery and dust removal system

A dust removal system, high and medium temperature technology, applied in the direction of improving energy efficiency, furnace, waste heat treatment, etc., can solve the problems of high investment cost, large wet dust removal resistance, too many conversion links, etc., and achieves simple and convenient installation and speed regulation. , The effect of improving energy utilization and increasing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific drawings and embodiments.

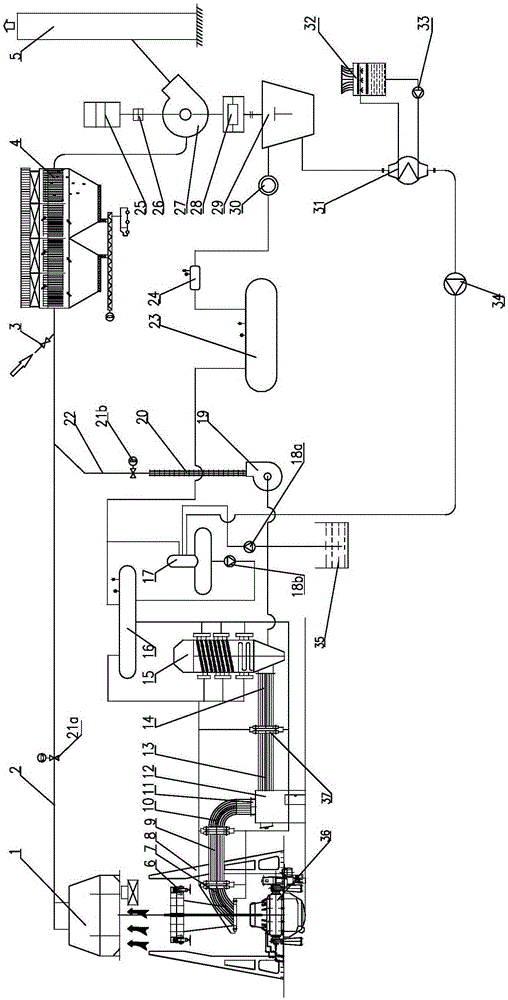

[0035]As shown in the figure: the AOD furnace dust high temperature waste heat positive energy recovery and dust removal system in the embodiment is mainly composed of variable flow roof hood 1, low temperature pipe 2, air mixing valve 3, bag filter 4, exhaust pipe 5 , electric mobile trolley 6, vaporization flue suction mask 7, smoke deflector exhaust hood 8, first vaporization flue section 9, second vaporization flue section 10, stainless steel compensator 11, combustion settling chamber 12 , the third vaporization flue section 13, the fourth vaporization flue section 14, finned tube waste heat boiler 15, steam drum 16, thermal deaerator 17, water inlet pump 18a, water delivery pump 18b, booster fan 19, Fin pipeline 20, electric multi-leaf butterfly valve 21a, electric multi-leaf butterfly valve 21b, high-temperature pipeline 22, steam heat accumulator 23, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com