Method and device for controlling engine of hybrid electric vehicle

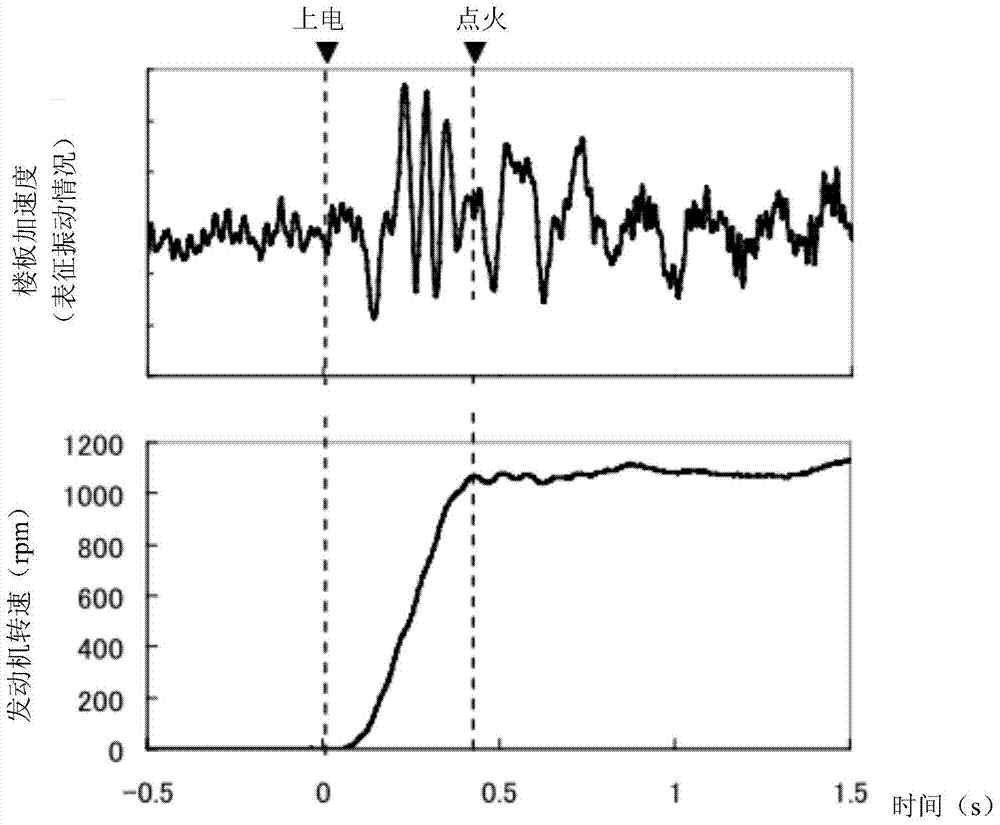

A hybrid electric vehicle and control method technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as large torque drop, acceleration fuel consumption degradation, engine power output reduction, etc., to overcome vibration and reduce torque shock , The effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

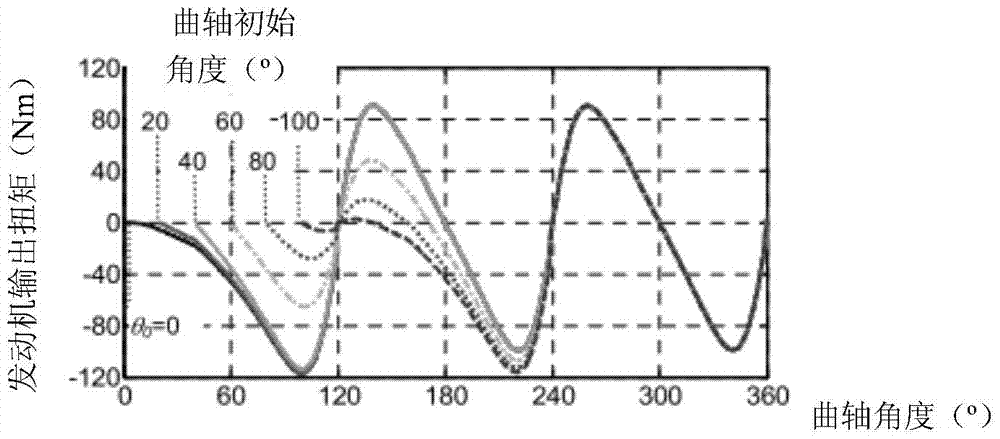

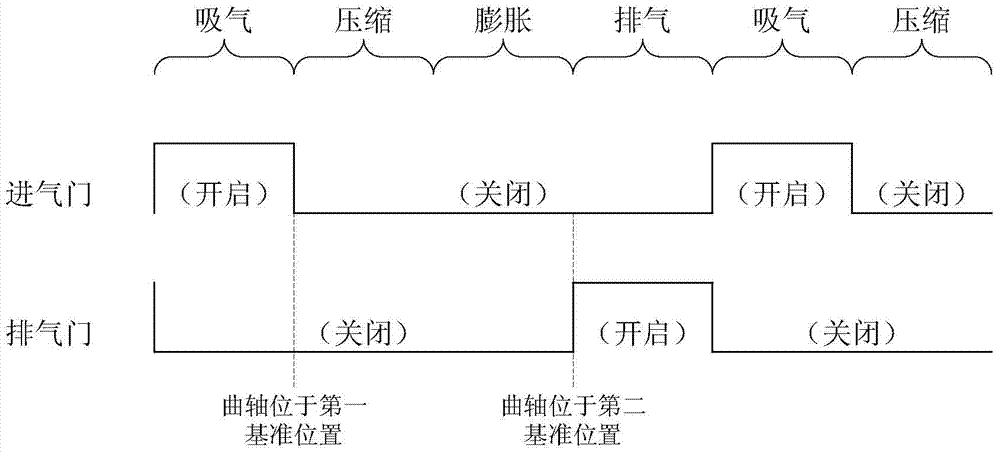

[0019] The control method of the hybrid electric vehicle engine of the present application is as follows: for the direct-connected hybrid electric vehicle, during the normal operation of the engine, the working cycle of the four-stroke engine is executed according to the existing control method. In the process of starting or stopping the engine, the opening time of the intake valve is not changed, but an additional opening time of the exhaust valve is added. The starting point of the additional opening time is within the range of 5 degrees to 30 degrees after the crankshaft position is located at the first reference position, and the end point of the additional opening time is within the range of 30 degrees to 0 degrees before the crankshaft position is located at the second reference position . The first reference position refers to the crankshaft position when the intake valve is closed when the engine is running normally. The second reference position refers to the cranksh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com