Surface treatment method for base course of asphalt pavement

A technology of asphalt pavement and base layer, which is applied in the field of pavement construction, and can solve the problems of interlayer transition, shear fault or sliding separation, unable to meet the bearing capacity, including strength and stiffness, etc., to achieve improved shear strength and increase shear resistance Deformation ability, effect of improving shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The asphalt pavement paving construction method of the present embodiment comprises the following steps:

[0027] Step 1. Fill the base layer in layers. The thickness of each layer is 10-20cm. The material of the base layer must meet the requirements of JTJ034-2000 "Technical Specifications for Construction of Highway Pavement Base Layer"; the base layer is divided into two layers;

[0028] Step 2. Use the grass-roots paving equipment to level the grass-roots paving;

[0029] Step 3: Carry out initial compaction on the base layer, and the compaction degree is ≥98%;

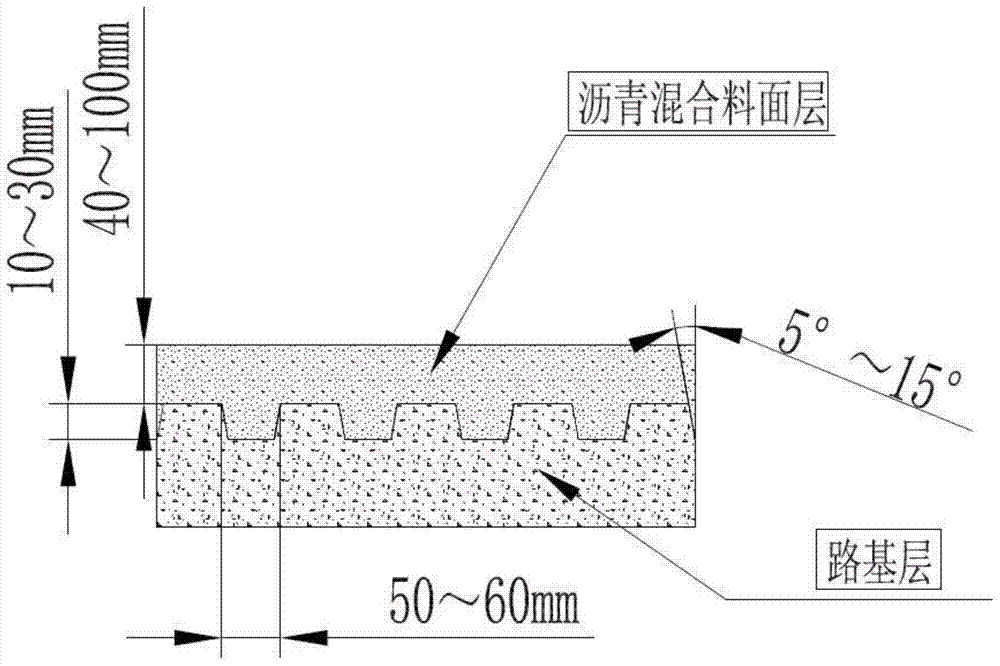

[0030] Step 4: Compressing the base layer, the longitudinal section of the base layer has a trapezoidal tooth structure, and the trapezoidal tooth structure includes at least one group of adjacent trapezoidal teeth and trapezoidal tooth grooves, and the length of the upper bottom of the trapezoidal teeth is less than The length of the lower bottom, the length of the upper bottom of the trapezoidal tooth gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com