Washing machine detergent automatic put system with spray and put function

A technology of automatic feeding and detergent, which is applied in the field of washing machines, can solve the problems of long pipelines, large differences in precision control, and affecting maintenance, etc., and achieve the effects of reasonable storage space, increased chamber volume, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

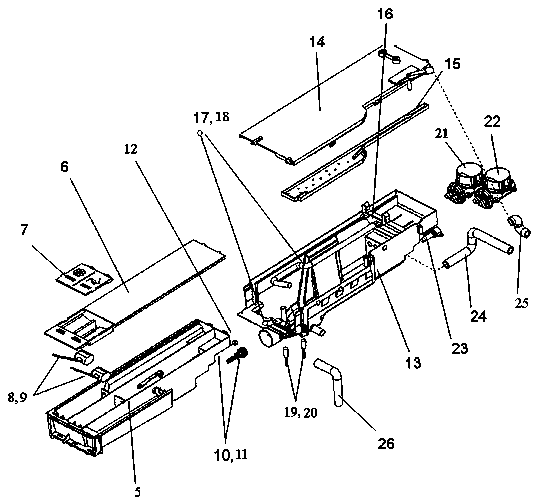

[0033] Below in conjunction with the accompanying drawings and embodiments, the washing machine automatic injection detergent system with spray injection function of the present invention will be further described in detail, in order to understand the structural composition and working process of the present invention more clearly, but it cannot be based on this To limit the protection scope of the present invention.

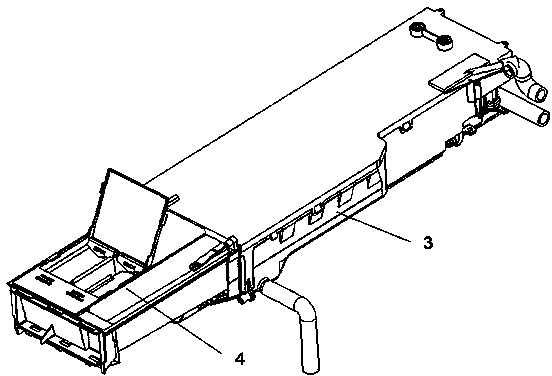

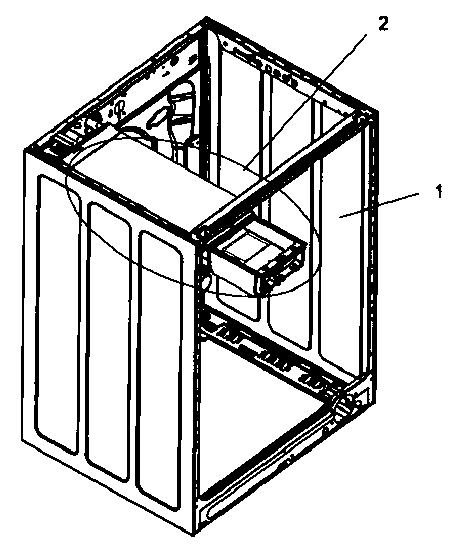

[0034] see Figure 1 to Figure 7 , the present invention provides an automatic detergent delivery system for a washing machine with a spray delivery function, wherein the automatic delivery detergent system 2 is mainly composed of two major components: a housing, a drawer assembly 3 and a drawer assembly 4, and the automatic delivery detergent system 2 is fixed on the washing machine casing 1.

[0035]The drawer assembly 4 can be freely pushed and pulled into the housing and the extraction assembly 3 through the card slot. The housing and the extraction assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com