Linen yarn warping and slashing technology

A yarn and flax technology, which is applied in the field of warping and sizing technology, can solve the problems of many falling objects in the weaving workshop, low weaving efficiency, and difficulty in fitting hairiness, etc., and achieve the goals of saving sizing costs, improving efficiency, and increasing unit output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

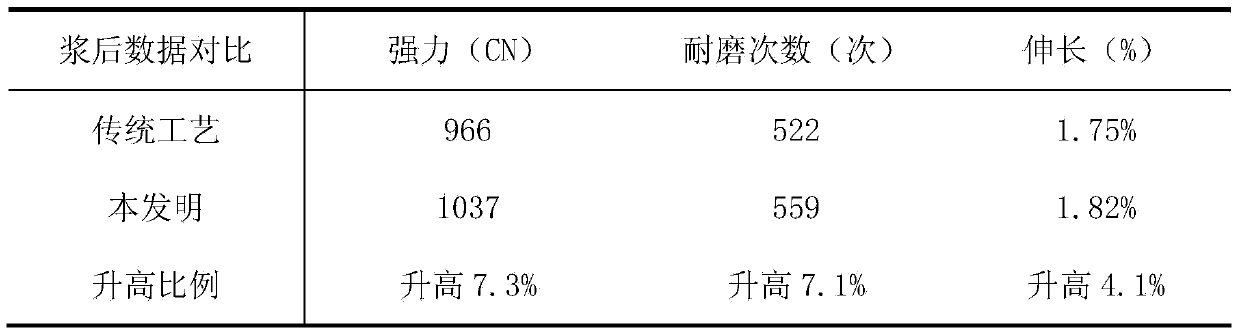

[0014] Example 1, variety: A05A05P0015, specification: L21*L21*50*48*68 / 60*48*57 / 58, weave: 1 / 1; process requirement: number of warp yarns 685*5.

[0015] 1) Pretreatment of warping yarn: bag the flax yarn, place it on a tray, cover it with a nylon net, and then pull it to a weaving workshop with a constant temperature of 30° for 12 hours to regain moisture. The moisture content of the flax yarn is 10.25%.

[0016] 2) Yarn warping: Deviation-type tension control process is adopted, water is sprinkled and humidified, and the linen yarn in the middle part of the warping frame is controlled by 6 grids. The weight of the tension sheet is 4 grams, and the actual measurement of the tension of a single yarn is 4-6CN , warp beam yarn hardness 62-65 (unit), 4 flax yarns located on both sides of the middle part use 10 grid tension control.

[0017] 3) Sizing: No sizing is required during sizing. The sizing rollers, pressure rollers, and contact rollers in the sizing machine are all in t...

Embodiment 2

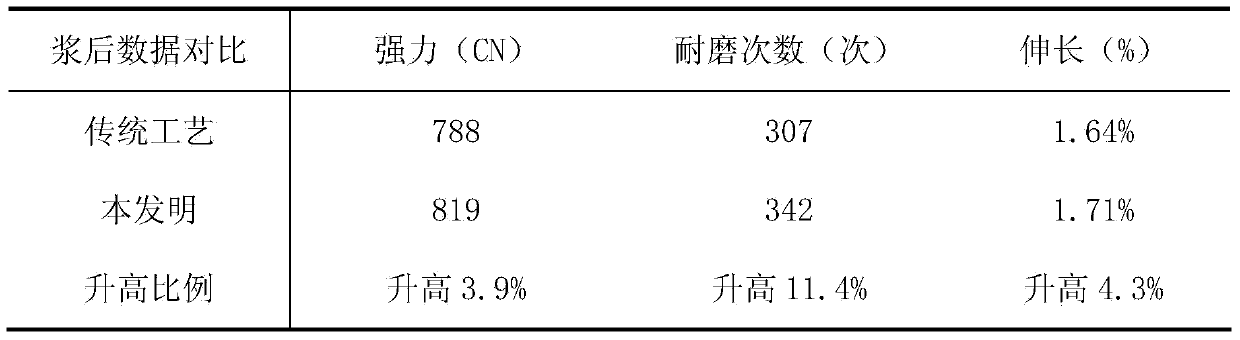

[0020] Example 2, variety: A05A05P0017K, specification: L17*L17*58*52*64 / 62*54*57 / 58, weave: 1 / 1; process requirement: number of warp yarns 604*6.

[0021] 1) Pretreatment of warping yarn: bag the flax yarn, put it on the tray, and cover it with nylon net, and then pull it to the weaving workshop with a constant temperature of 30° for 12 hours, and the moisture content of the flax yarn is 8.45%.

[0022] 2) Yarn warping: Deviation-type tension control technology is adopted. The linen yarn in the middle part of the warping frame is controlled by 7 grids of tension. The weight of the tension piece is 4 grams. The actual measurement of the tension of a single yarn is 6-8CN, and the warp beam The yarn hardness is 62-65 units, and each of the 4 flax yarns located on both sides of the middle part uses 10 grids of tension control.

[0023] 3) Sizing: No sizing is required during sizing. The sizing rollers, pressure rollers, and contact rollers in the sizing machine are all in the ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tension | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com