A kind of preparation method of non-linear optical crystal surface anti-reflection protection film

A technology of nonlinear optics and crystal surfaces, applied in chemical instruments and methods, crystal growth, post-processing details, etc., to solve the problem of deliquescence, good environmental stability, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

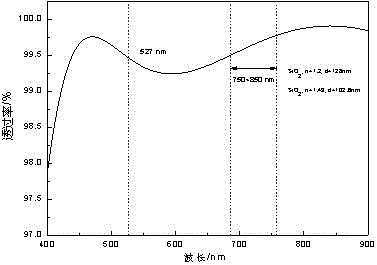

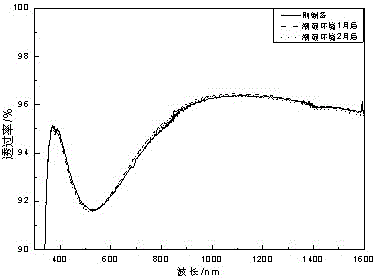

Image

Examples

Embodiment 1

[0022] Distilled and purified methyltriethoxysilane (MTES), absolute ethanol (EtOH), hydrochloric acid (HCl), deionized water (H 2 O) After mixing and stirring according to the molar ratio of 1:24:0.6:1.5, place it in a stable environment (20°C, relative humidity 30%) for aging for 7 days, then use toluene as a solvent to replace ethanol, and remove residual HCl and water, that is A transparent polysiloxane moisture-proof film sol coating solution can be obtained. During the reaction process, water needs to be dissolved in ethanol first, and then slowly added to the mixed solution of MTES, ethanol and hydrochloric acid.

[0023] Tetraethyl orthosilicate (TEOS), ammonia (NH 3 ·H 2 O) and absolute ethanol (EtOH) were mixed and stirred evenly according to the molar ratio of 1:3:50, and placed in a stable environment (20°C, relative humidity 30%) for aging for 10 days to obtain a light blue silica sol. Then add PEG100 and hexamethyldisilazane into the silica sol (molar ratio 0....

Embodiment 2

[0027] Dimethyldiethoxysilane (DDS), absolute ethanol (EtOH), acetic acid (CH 3 COOH), deionized water (H 2 O), fully stirred at room temperature for 2 hours according to the molar ratio of 1:30:2:1, then left to age for 7 days, then replaced ethanol with n-butanol as a solvent, and removed residual acetic acid and water at the same time to obtain transparent Moisture-proof film sol coating solution. Pay attention to the order of adding raw materials during the preparation process, H 2 O was first dissolved in half of ethanol, and then added dropwise to the other half of the mixture of EtOH, DDS and acetic acid. Otherwise, the reaction speed is too fast, and the sol will form a suspension.

[0028] Tetraethyl orthosilicate (TEOS), ammonia (NH 3 ·H 2 O) and absolute ethanol (EtOH) were mixed and stirred evenly according to the molar ratio of 1:3:50, and placed in a stable environment (20°C, relative humidity 30%) for aging for 10 days to obtain a light blue silica sol. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com