High-efficiency barrel plating washing system

A cleaning system and barrel plating technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of high waste water treatment cost, large solution loss, large loss, etc., achieve good water saving effect, save solution, and reduce processing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further explained and illustrated:

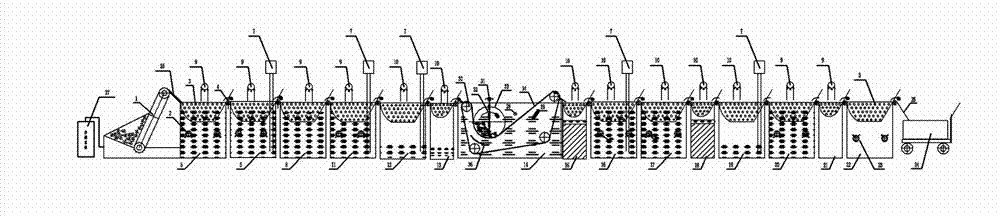

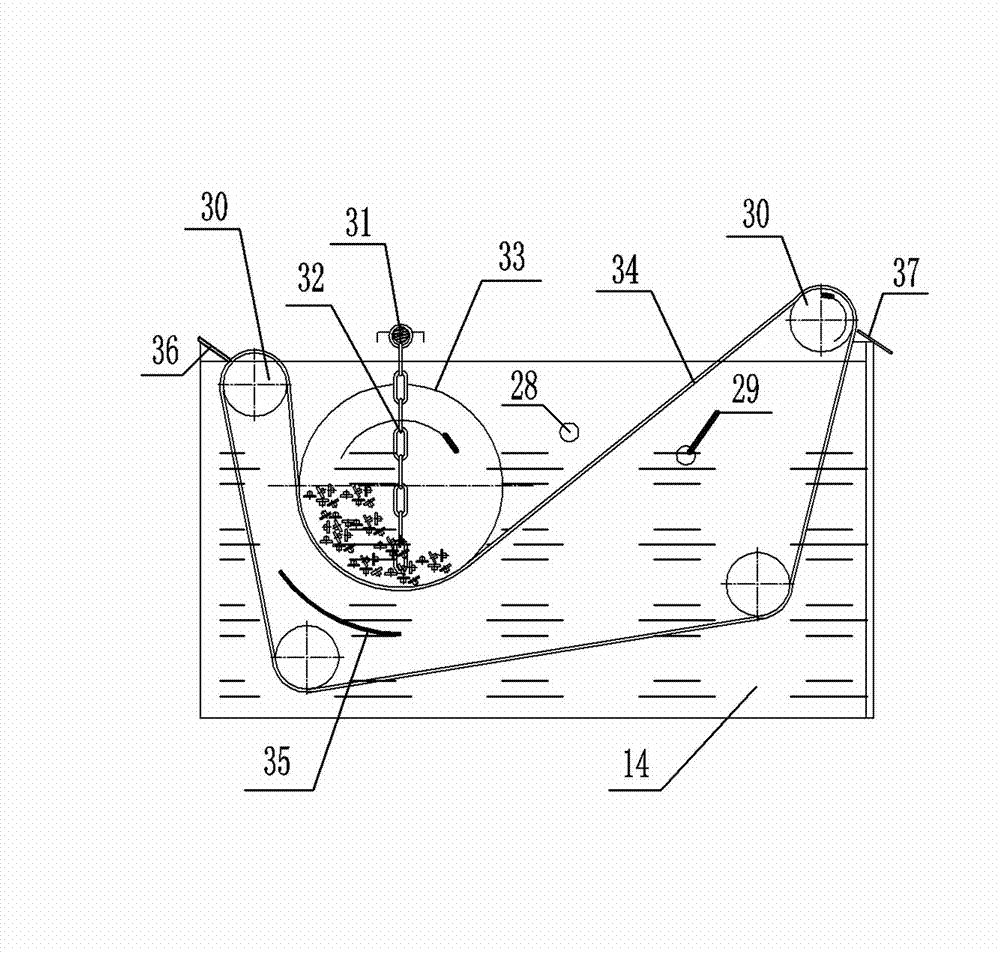

[0022] see figure 1 and figure 2 , a high-efficiency barrel plating cleaning system, comprising a control system 27, a parts hoist 1 and a barrel plating cleaning tank group, the barrel plating cleaning tank group successively includes an alkaline water cleaning tank 5, a hot water cleaning tank 6, a weak acid cleaning tank 8, a soaking tank Cleaning tank 11, primary spray washing tank 12, secondary spray washing tank 13, barrel plating tank body 14, electroplating solution recovery tank 15, immersion spray tank 16, passivation tank 17, solution recovery tank 18, spray Shower tank 19, closed tank 20, blowing tank 21 and vibration drying tank 22, the upper ends of two adjacent tanks are all provided with turning mechanism 4.

[0023] Among them: alkaline water cleaning tank 5, hot water cleaning tank 6, weak acid cleaning tank 8, immersion cleaning tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com