Syrup heating tank

A technology for heating tanks and syrups, which is applied in sugar production, sugar production, glucose production, etc., and can solve problems such as easy solidification and blockage of the discharge port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

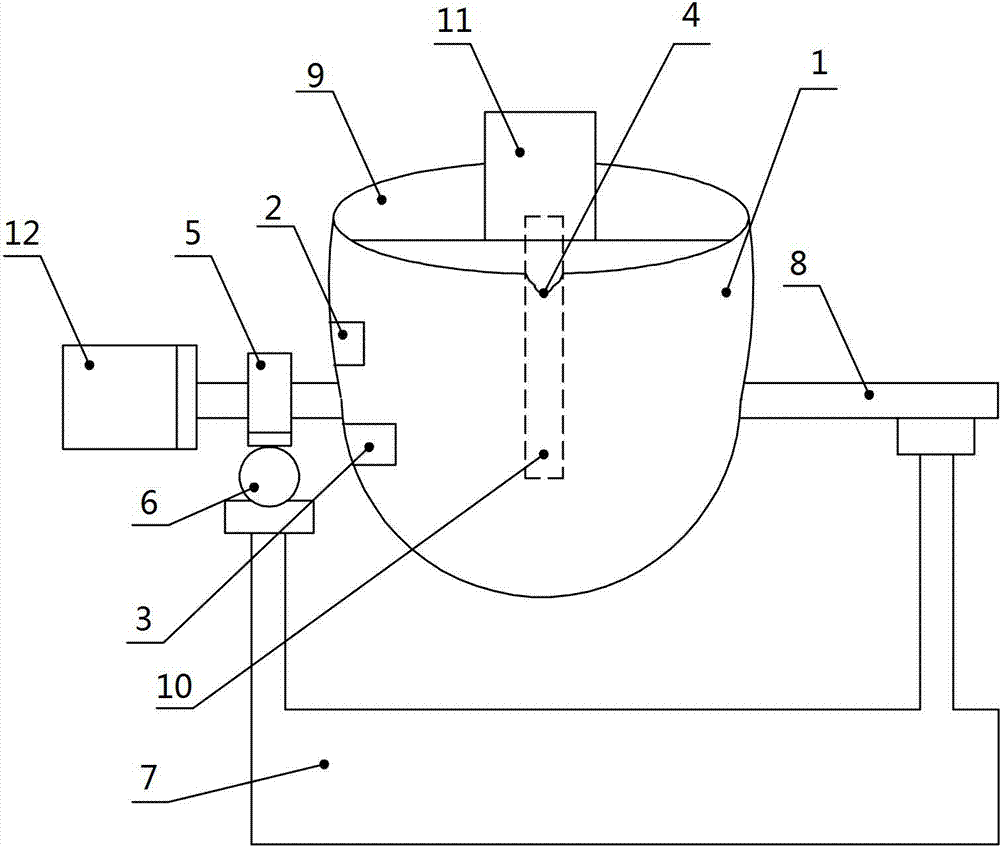

[0011] Such as figure 1 Shown: syrup heating tank, including syrup heating tank body 1, syrup heating tank body 1 is provided with feed port 2 and steam inlet 3, steam inlet 3 is connected with a hose, syrup heating tank body 1 is also provided with a pouring spout 4 and a pouring device, the pouring mouth 4 is located at the mouth of the syrup heating tank body 1, the pouring device is fastened on the syrup heating tank body 1, and the pouring device includes a worm gear 5, a worm screw 6, a support 7, a turning shaft 8 and a motor 12 , the worm 6 is fixed to the support 7, the worm 6 and the worm wheel 5 cooperate with each other, the turning shaft 8 is fixed to the turbine 5 and the end of the turning shaft 8 is fixed to the syrup heating tank body 1, and the motor 12 drives the worm wheel 5; the syrup heating tank body 1 The opening is provided with a cover body 9, which is provided with a stirring rod 10 extending into the syrup heating tank body 1 and a motor 11 driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com