Biomass-oil catalytic hydrogenation reaction device and catalytic hydrogenation method thereof

A technology of catalytic hydrogenation and biomass oil, which is applied in the fields of chemical engineering and energy engineering, to achieve the effects of catalytic hydrogenation reaction, catalyst regeneration, and increased hydrogen dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

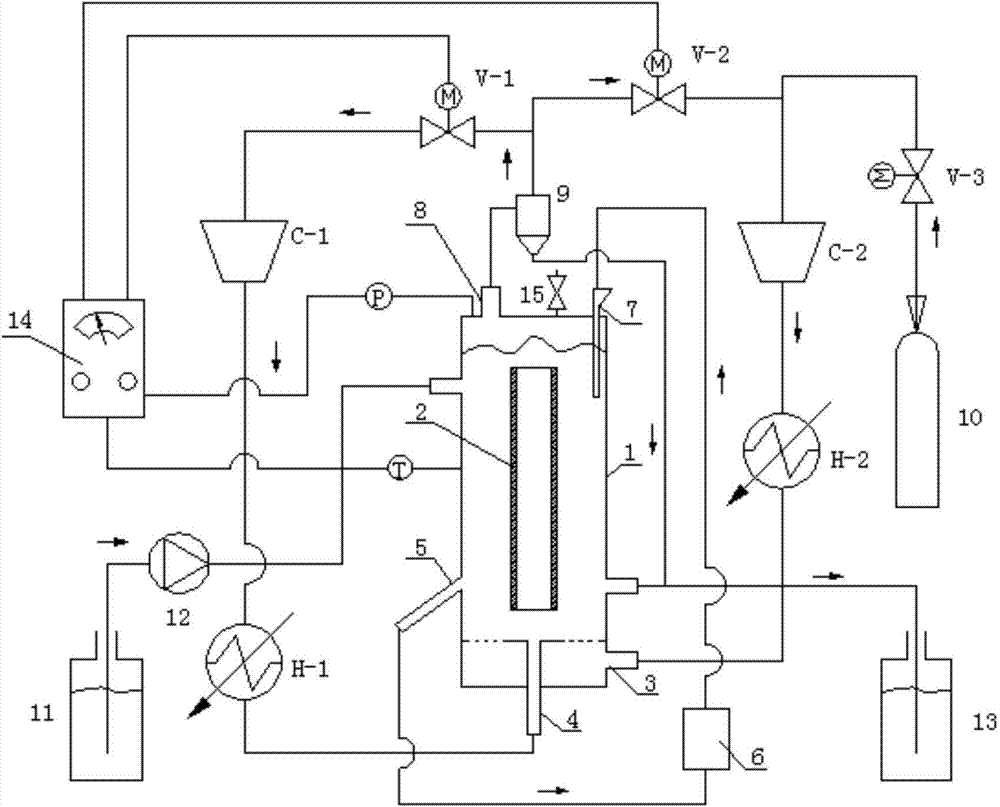

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 As shown, a biomass oil catalytic hydrogenation device includes a reaction tower 1, a riser 2 fixed in the inner cavity of the reaction tower 1 through a bracket, a temperature sensing probe set in the inner cavity of the reaction tower 1, and a 1 Pressure-sensitive probe in the inner cavity, catalyst regeneration device 6, gas-liquid separator 9, hydrogen source 10, biomass crude oil storage tank 11, oil delivery pump 12, refined oil storage tank 13, flow control device 14, first solenoid valve V-1, second solenoid valve V-2, third solenoid valve V-3, first compressor C-1, second compressor C-2, first heat exchanger H-1 and second heat exchanger H-2.

[0019] The top of the reaction tower 1 is provided with a catalyst inlet 7, a reaction gas outlet 8 and an exhaust valve 15, and the exhaust valve 15 is used to discharge miscellaneous gases su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com