Preparation method of biomass-based deinking agent

A technology based on deinking agent and biomass is applied in the field of preparation based on biomass-based deinking agent, which can solve the problems of low pulping yield of waste paper, low product quality and large water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method based on biomass-based deinking agent, comprising the following steps:

[0027] Weigh the sodium hydroxide solid and slowly dissolve it in water under stirring to make a sodium hydroxide aqueous solution with a mass percentage concentration of 20wt%. Add 5g sodium laurate particles to the sodium hydroxide aqueous solution. The mass ratio of the solution is 5:100; stir to obtain a uniform mixed solution, then add 2.5g of zinc oxide particles to the mixed solution, stir continuously, and add edible rapeseed oil 50 times the quality of sodium laurate to the system after mixing evenly , raise the temperature to 85°C at a heating rate of 1°C / min, and at the same time turn on the condensed water to cool the solution in the reflux reaction system and keep the temperature. After 10 hours of reaction, remove the product while it is hot and put it into a wide-mouthed container. After cooling, After being pulverized by a high-speed pulverizer, an anionic bioma...

Embodiment 2

[0029] The preparation method based on biomass-based deinking agent as described in Example 1, the difference is that,

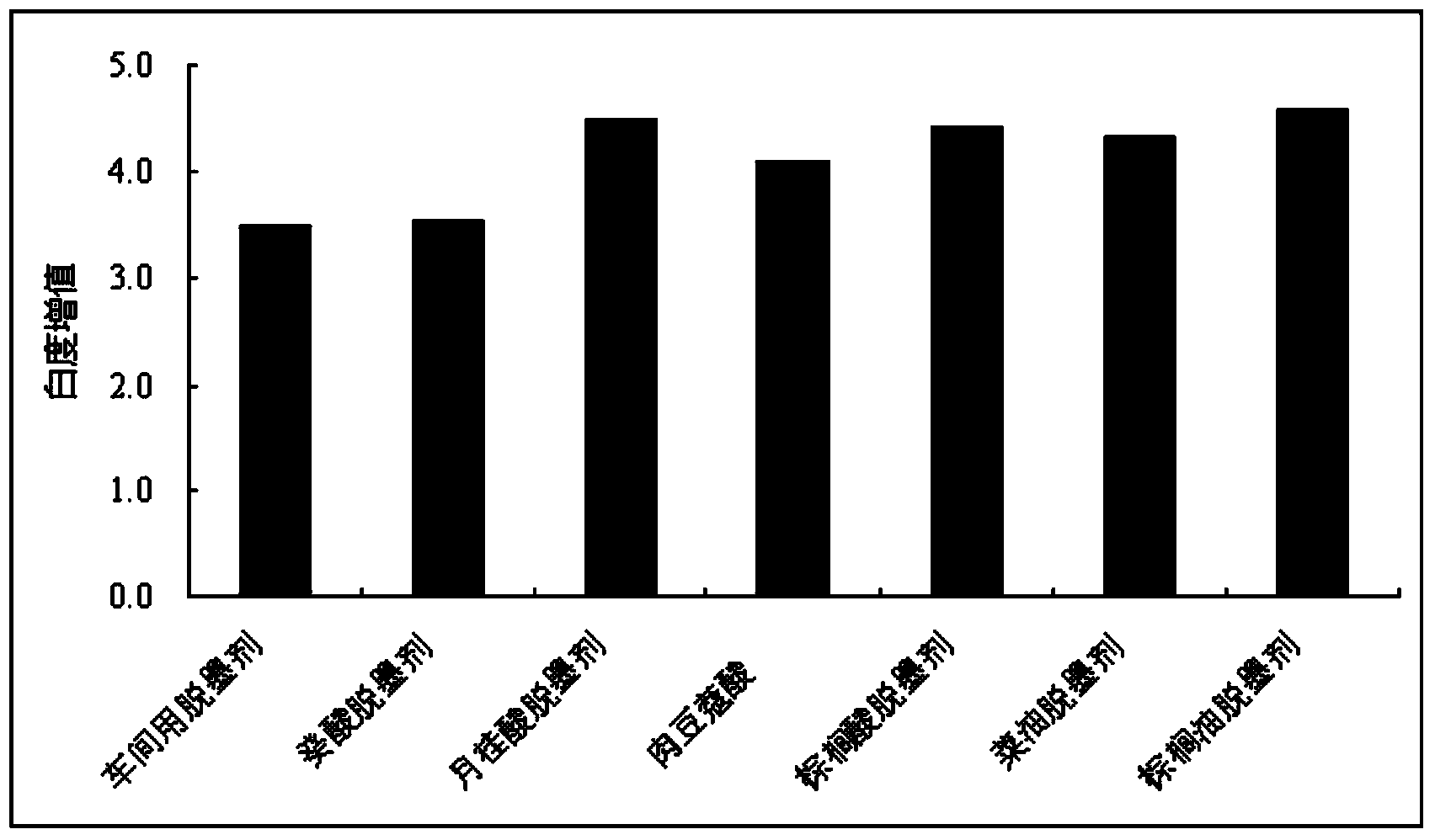

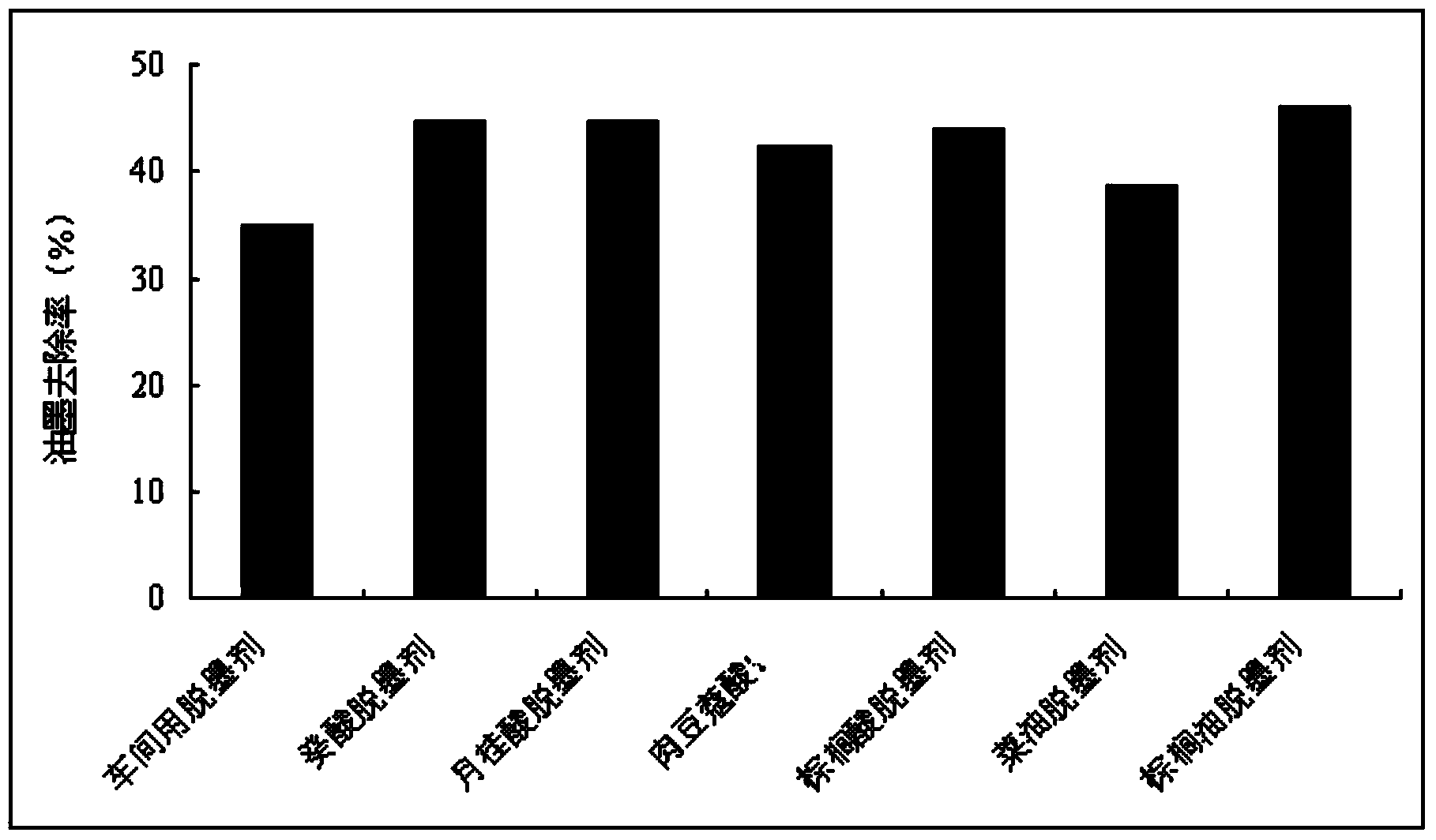

[0030] After mixing evenly, add palm oil of 55 times the quality of sodium laurate to the system, and raise the temperature to 90°C at a heating rate of 1°C / min to obtain an anionic biomass-based deinking agent, which is obtained in this example by whiteness meter detection The value-added whiteness of the deinking agent is 4.8, and the ink removal rate can reach 46%.

Embodiment 3

[0032] The preparation method based on biomass-based deinking agent as described in Example 1, the difference is that,

[0033] After mixing evenly, add capric acid with 52 times the mass of sodium laurate to the system, and raise the temperature to 95°C at a heating rate of 1°C / min to obtain an anionic biomass-based deinking agent, which is obtained in this example by whiteness meter detection The value-added whiteness of the deinking agent is 3.6, and the ink removal rate can reach 45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com